In the realm of modern manufacturing, injection molding has emerged as a cornerstone technology, revolutionizing the production of intricate plastic and metal components. Central to this innovation are injection mold manufacturers, whose expertise and ingenuity drive the evolution of this industry. This article explores the vital role of injection mold manufacturers in shaping various sectors and propelling technological advancements.

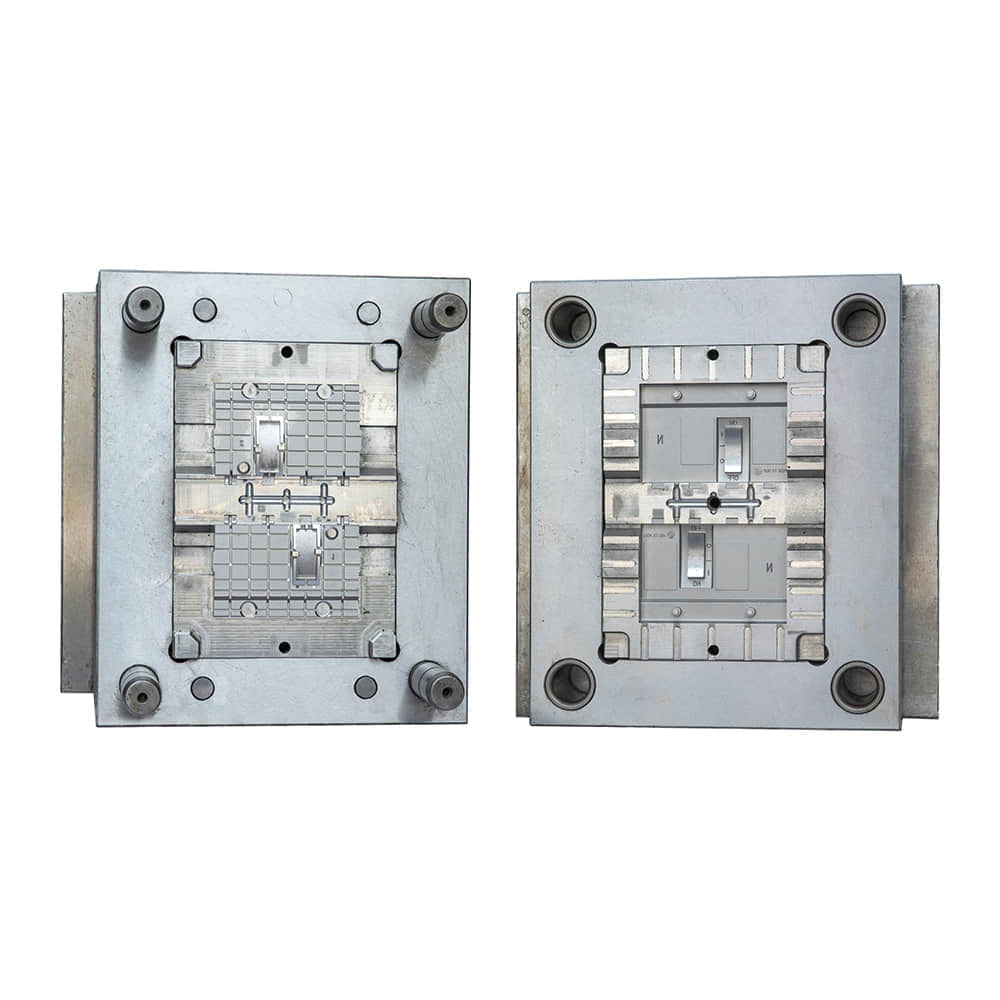

Injection mold manufacturers are the architects behind the molds that shape products ranging from consumer electronics to medical devices. Their craftsmanship determines the quality, precision, and efficiency of the manufacturing process. These professionals employ cutting-edge technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) to create highly detailed and customized molds. This level of precision guarantees that every product produced is consistent in quality and specification.

To meet the demands of an ever-evolving market, injection mold manufacturers have adopted innovative techniques. One such technique is 3D printing, which has not only expedited the mold prototyping process but has also facilitated the production of complex mold designs that were previously unachievable. This advancement has significantly reduced the time it takes to bring a new product to market while also minimizing development costs. In recent years, sustainability has become a focal point across industries. Injection mold manufacturers have risen to the challenge by implementing eco-friendly practices. By utilizing recyclable materials and optimizing the molding process to reduce waste, these manufacturers contribute to a greener manufacturing ecosystem. Additionally, their expertise in material selection ensures that the end-products are durable, extending the lifecycle of the products and further promoting sustainability. The medical sector, in particular, has benefited immensely from injection molding, thanks to the expertise of mold manufacturers. The production of intricate and sterile medical equipment demands a level of precision that traditional manufacturing methods struggle to achieve. Injection mold manufacturers have bridged this gap by creating molds that can produce intricate medical components with unparalleled accuracy. This has not only revolutionized the medical field but has also saved lives through the production of reliable, high-quality medical devices. Automotive manufacturers also rely on injection molding for a wide array of components, from interior aesthetics to critical under-the-hood parts. Injection mold manufacturers play a pivotal role in these industries by crafting molds that produce parts that meet rigorous safety standards, are visually appealing, and enhance the overall driving experience. Their ability to produce large quantities of components in a relatively short time ensures that the automotive industry can keep up with consumer demand. In conclusion, injection mold manufacturers are at the forefront of innovation in modern manufacturing. Their expertise, coupled with technological advancements like 3D printing, has redefined what is possible in terms of precision, efficiency, and sustainability. From healthcare to automotive industries, their contributions have elevated the quality of products and pushed the boundaries of design. As technology continues to advance, the role of injection mold manufacturers will remain integral to the evolution of various sectors, consistently driving progress and shaping the future of manufacturing.