In the realm of modern manufacturing, where precision and efficiency are paramount, the role of a Metal Stamping Die Manufacturer stands out as a cornerstone of innovation. Metal stamping, a process that transforms flat metal sheets into intricate shapes with remarkable accuracy, owes much of its success to the expertise and craftsmanship of these manufacturers. This article delves into the world of Metal Stamping Die Manufacturers, exploring their significance, the processes they employ, and the impact they have on various industries.

The Significance of Metal Stamping Die Manufacturers

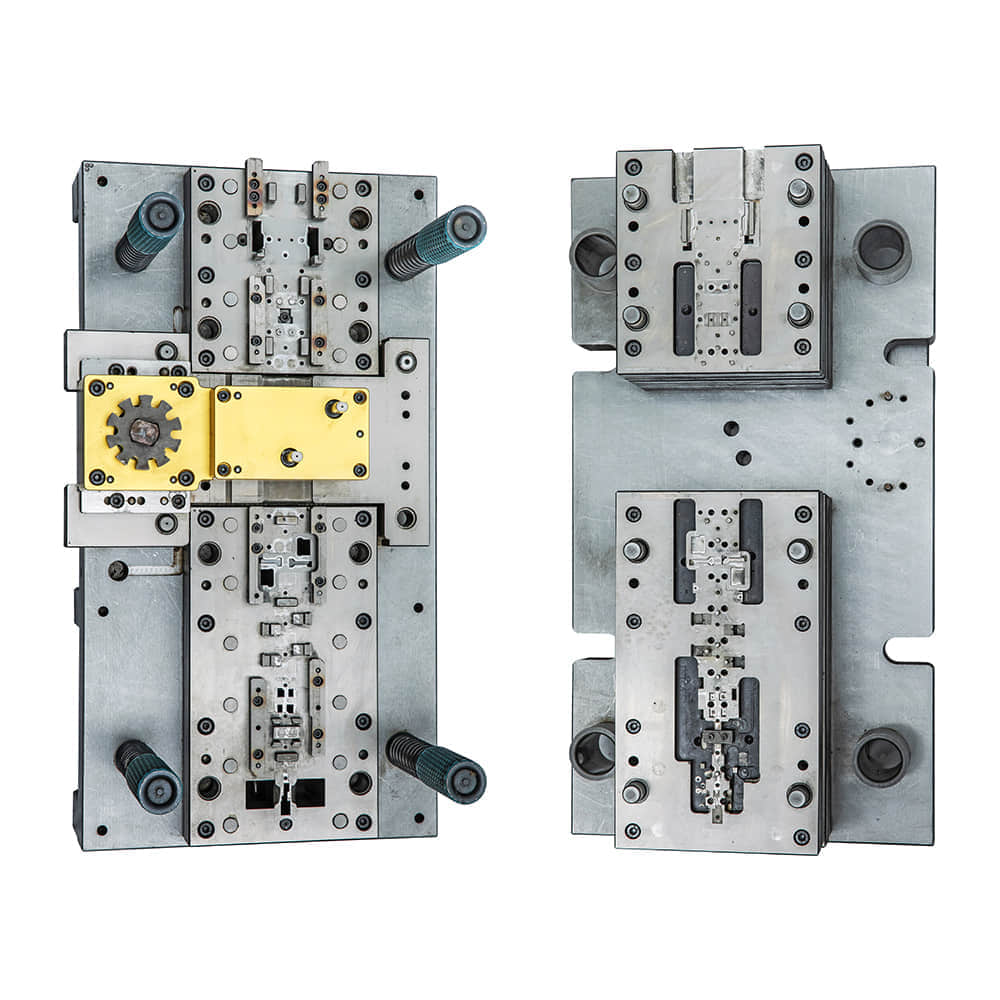

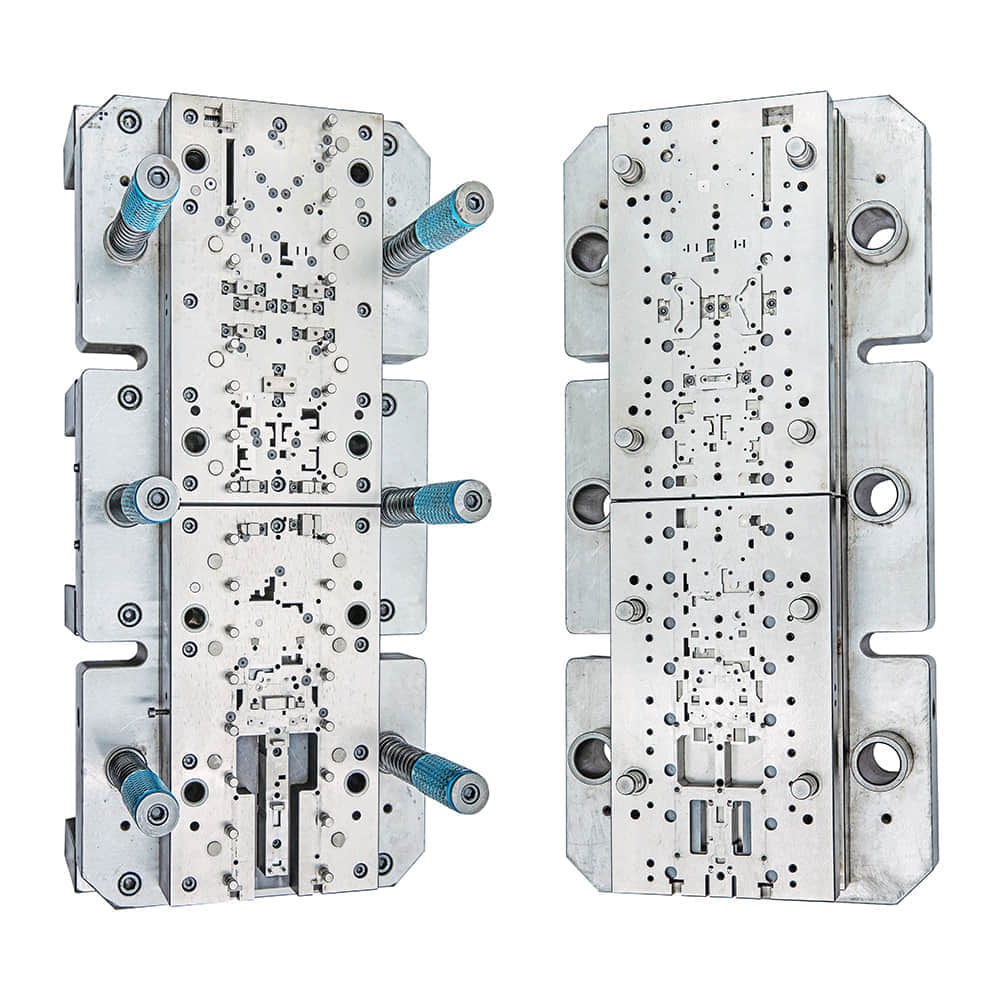

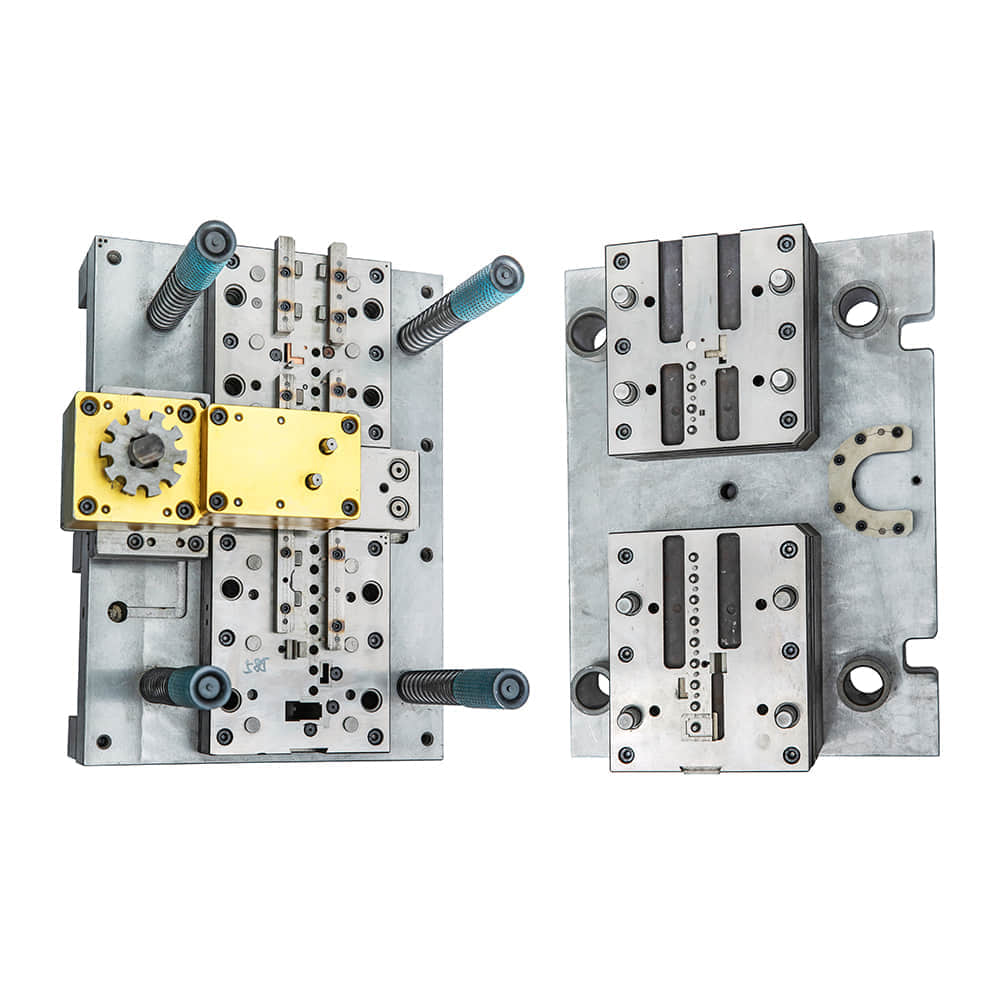

Metal Stamping Die Manufacturers play a vital role in the manufacturing landscape by creating the molds, or dies, that are used to shape metal sheets into various components and products. These manufacturers are at the forefront of technological advancements, developing cutting-edge solutions to meet the demands of industries like automotive, electronics, aerospace, and more. Their ability to produce intricate and consistent parts with high efficiency makes them indispensable in modern production processes. Precision in Manufacturing At the heart of a Metal Stamping Die Manufacturer’s work lies precision. These manufacturers utilize advanced software, computer-aided design (CAD), and computer-aided manufacturing (CAM) systems to create intricate die designs with micron-level accuracy. The dies they produce are tailored to the specific requirements of each project, ensuring that every component produced is uniform and of the highest quality. The Manufacturing Process The journey of a metal sheet from raw material to a finished stamped component involves several crucial steps. First, the Metal Stamping Die Manufacturer collaborates with the client to understand their needs, specifications, and design requirements. Then, they conceptualize the die design using specialized software, meticulously considering factors like material characteristics, part geometry, and production volume. Once the design is finalized, the manufacturing process begins. High-quality tool steels are chosen to construct the dies, ensuring durability and precision throughout the production cycle. Advanced CNC machining techniques are employed to craft the dies to exact specifications. The result is a precision tool capable of withstanding the pressures and forces involved in metal stamping. Impact on Industries The impact of Metal Stamping Die Manufacturers reverberates through numerous industries. In the automotive sector, these manufacturers contribute to the production of intricate parts used in engines, transmissions, and chassis assemblies. In electronics, they help create components for devices that have become integral to daily life. Furthermore, the aerospace industry relies on their expertise to fabricate components that meet stringent safety and performance standards. Innovation and Future Trends Metal Stamping Die Manufacturers continue to push the boundaries of innovation. As new materials and technologies emerge, they adapt their processes to accommodate these changes. The integration of automation and artificial intelligence into metal stamping processes enhances efficiency, reduces waste, and accelerates production times. The concept of sustainability is also gaining traction in the industry. Metal Stamping Die Manufacturers are exploring environmentally friendly materials, energy-efficient processes, and waste-reduction techniques to minimize their ecological footprint. Conclusion In the intricate dance of modern manufacturing, Metal Stamping Die Manufacturers stand as pioneers of precision and innovation. Their expertise shapes the foundation of industries worldwide, bringing to life the products that define our modern lives. As technology advances and industries evolve, these manufacturers will continue to play a pivotal role in driving progress and shaping the future of manufacturing.