In modern industrial automation and control systems, the industrial relay plays a pivotal role in controlling high-power devices and ensuring the smooth functioning of various applications. Whether in manufacturing, power distribution, or mechanical operations, industrial relays act as intermediaries between low-power control circuits and high-power electrical equipment. This article explores the working principle, types, applications, and importance of industrial relays in enhancing industrial operations.

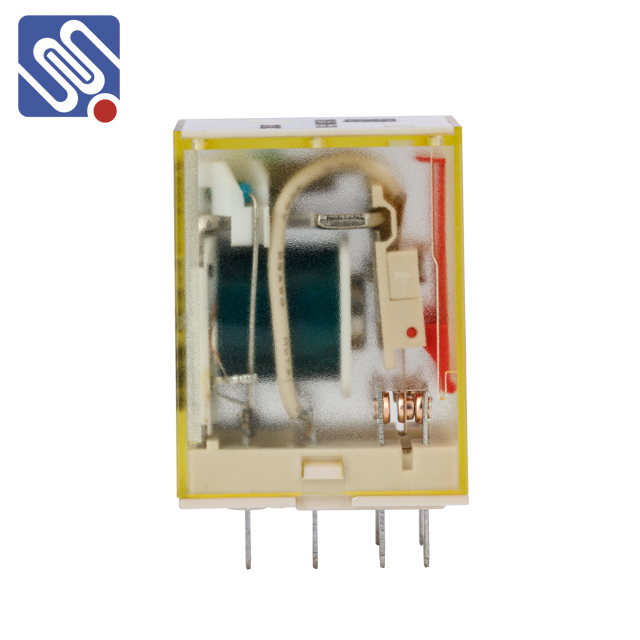

Working Principle of Industrial Relays The basic principle of an industrial relay lies in electromagnetic functionality. A relay consists of a coil, armature, contacts, and a spring mechanism. When a control voltage is applied to the relay’s coil, it generates a magnetic field, causing the armature to move. The movement of the armature opens or closes the contacts, which then controls the flow of electricity through the circuit. The control circuit typically operates at a lower voltage and current, while the relay enables switching of higher voltage and current circuits. This allows a small signal to control a large power circuit, making it essential for automation systems.