Flow Control Solenoid Valves (FCSV) play a crucial role in regulating fluid flow in various automation systems. By combining the characteristics of solenoid valves with advanced flow control capabilities, these valves offer a precise and reliable method of managing the movement of liquids and gases in industrial applications. This article explores the structure, working principles, applications, and benefits of Flow Control Solenoid Valves, as well as their significance in modern automation systems.

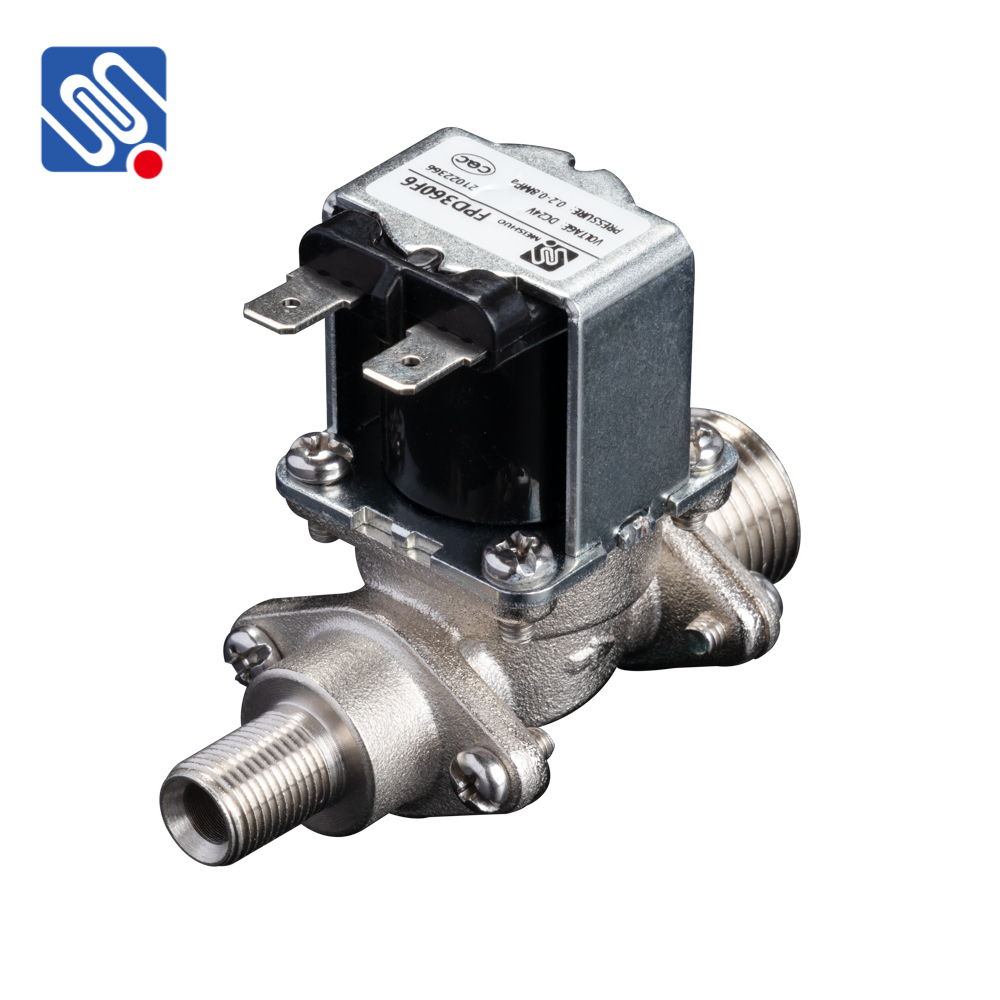

What is a Flow Control Solenoid Valve? A Flow Control Solenoid Valve is a type of valve that uses electromagnetic control to regulate the flow rate of fluids such as water, oil, air, or gas in a system. These valves are designed to open or close based on electrical signals sent from a control system, enabling automated, precise control of fluid flow. The solenoid component of the valve is an electromagnetic coil that, when energized, creates a magnetic field to move a valve element, typically a plunger or spool, which adjusts the flow passage. How Does It Work? The operation of a Flow Control Solenoid Valve is relatively simple yet highly effective. The valve consists of a solenoid coil, a valve body, and a valve element (plunger or spool). When an electrical signal is sent to the solenoid coil, it generates a magnetic field that moves the valve element. This movement adjusts the size of the flow passage, regulating the rate at which fluid passes through the valve.