In the realm of industrial operations, where safety and reliability are paramount, the role of explosion-proof electric butterfly valves cannot be overstated. As an essential component in managing fluid flow, these valves are particularly crucial in hazardous environments where the risk of explosions is significant. An OEM (Original Equipment Manufacturer) specializing in explosion-proof electric butterfly valves provides a vital service by ensuring that these critical components meet rigorous safety and performance standards.

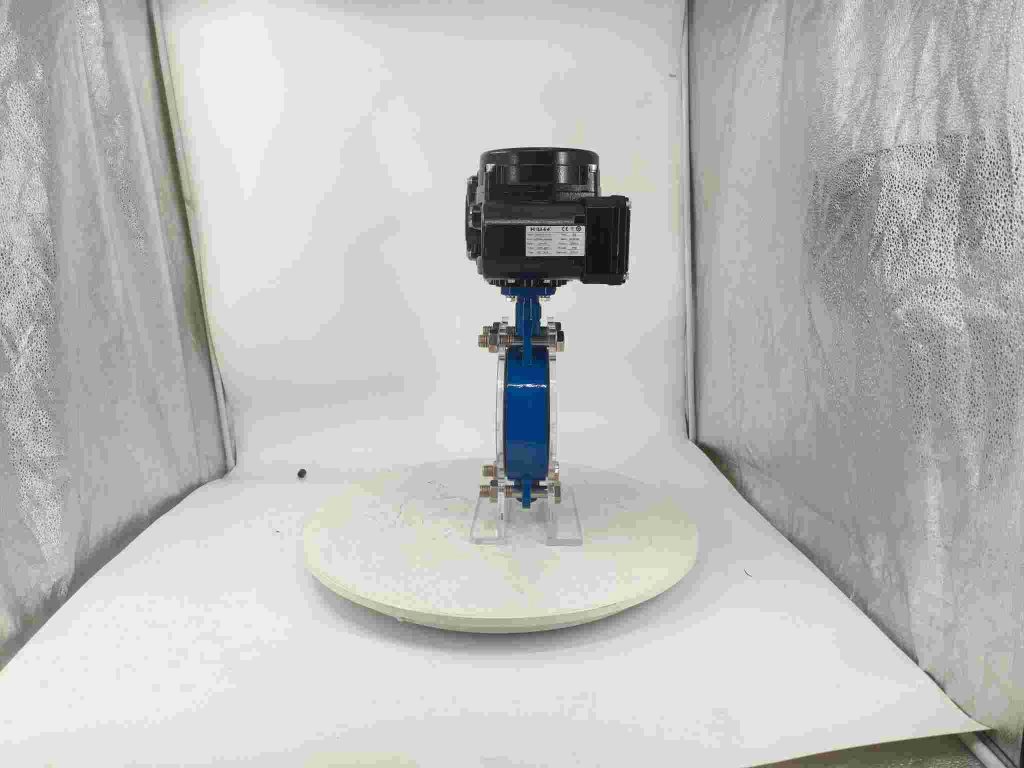

Explosion-proof electric butterfly valves are engineered to withstand extreme conditions, including explosive atmospheres, high pressures, and corrosive substances. They are typically used in industries such as oil and gas, chemical processing, and mining, where the potential for hazardous conditions is high. The primary function of these valves is to control the flow of liquids and gases while preventing the possibility of ignition and explosion, which can be catastrophic in such environments.

An OEM manufacturer of explosion-proof electric butterfly valves must adhere to strict international standards and regulations. This includes compliance with standards such as ATEX (Atmosphères Explosibles) in Europe or NEC (National Electrical Code) in the United States. These standards ensure that the valves are designed, tested, and certified to perform safely and reliably in explosive atmospheres. The manufacturing process involves rigorous testing, including pressure and leak tests, to ensure that the valves can operate under extreme conditions without failure. One of the key advantages of working with an OEM manufacturer is the ability to customize solutions to meet specific operational needs. Each industrial application may have unique requirements in terms of valve size, material, and actuation method. OEMs offer tailored solutions, providing valves that are designed and built to precisely fit the operational environment. This customization not only enhances performance but also contributes to overall safety by ensuring that the valve operates correctly and efficiently.