In today’s industrial landscape, safety is a top priority, particularly in environments where hazardous gases, chemicals, or dust are present. The potential for explosions in such environments demands the use of specialized equipment designed to mitigate risks. One such crucial component is the explosion-proof electric butterfly valve, a device specifically engineered to maintain safety, prevent ignition, and offer reliable control in volatile settings. OEM manufacturers of these valves play a pivotal role in ensuring that industries adhere to safety standards while benefiting from the operational advantages these valves provide.

Understanding Explosion-proof Electric Butterfly Valves

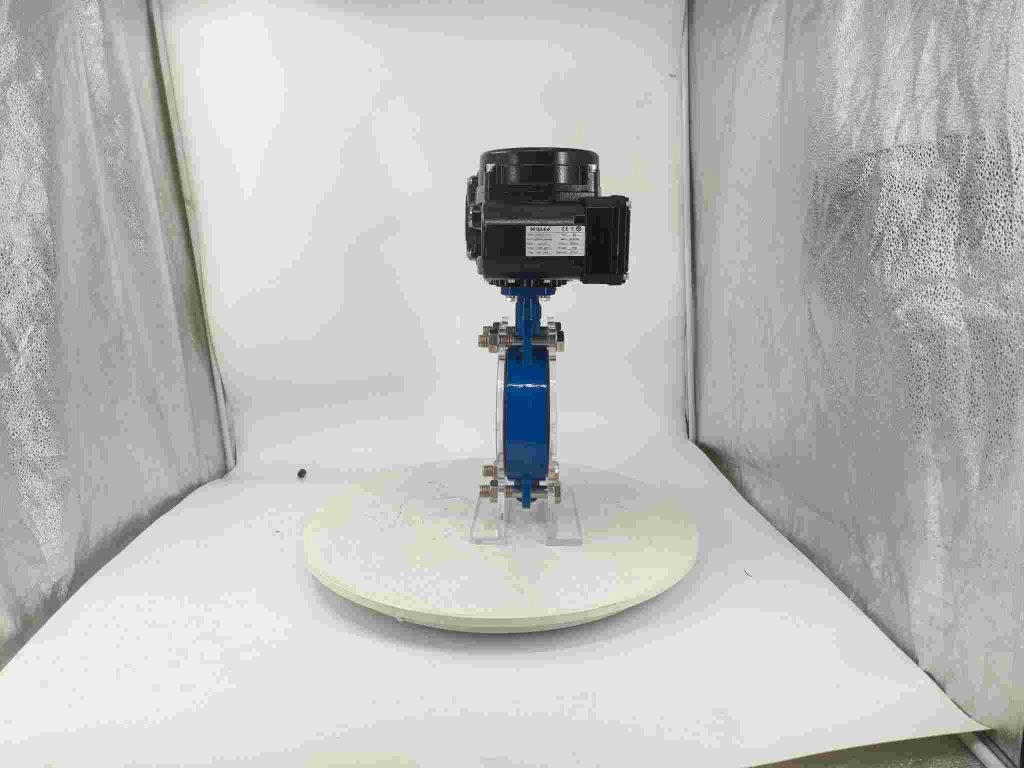

An explosion-proof electric butterfly valve combines the functionality of a butterfly valve, which is a flow control device, with an electric actuator that provides automation and remote control capabilities. The key differentiator of these valves is their explosion-proof design, which is crucial in environments where flammable gases, vapors, or dust particles are present. These valves are designed to contain or withstand potential explosions, preventing sparks, heat, or electrical malfunctions from igniting hazardous materials. The valve itself is typically made of durable materials such as stainless steel, cast iron, or other corrosion-resistant alloys, with seals designed to handle high temperatures and pressures. The actuator is equipped with features to prevent electrical faults from triggering an explosion. Together, these components offer precise control over the flow of materials and ensure safety in environments where the risk of an explosion is high.