In industries such as oil and gas, chemical processing, and mining, safety is a paramount concern. The presence of volatile gases, flammable liquids, or dust in certain environments makes it critical to use equipment designed to minimize risks. One such essential component is the Explosion-proof electric butterfly valve, a device engineered to control the flow of fluids while ensuring safety in potentially hazardous conditions. These valves, produced by Explosion-proof electric butterfly valve OEM manufacturers, play a vital role in minimizing the risk of explosions, reducing operational hazards, and ensuring the integrity of industrial processes.

What is an Explosion-proof Electric Butterfly Valve?

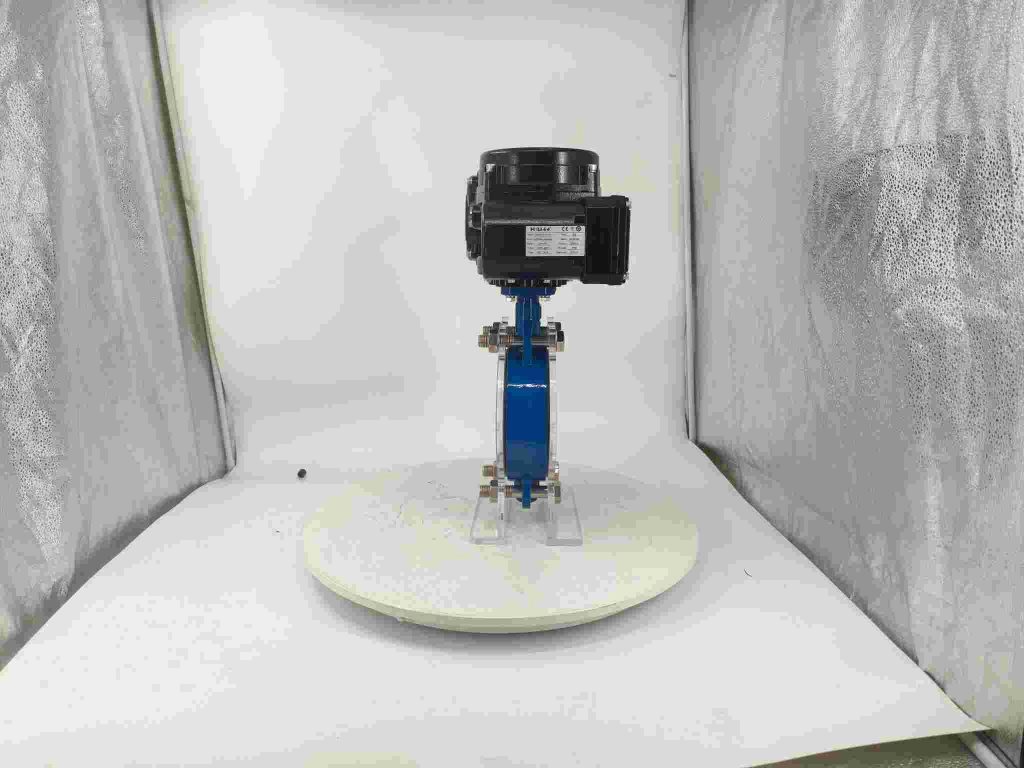

An Explosion-proof electric butterfly valve is a type of valve designed to regulate the flow of fluids, gases, or slurries in industrial applications, particularly in environments with explosive atmospheres. The primary feature that distinguishes these valves from regular valves is the explosion-proof actuator, which is specially designed to operate safely in areas with an increased risk of explosions. These valves consist of a butterfly disk that rotates within a pipe to control the flow of material. The electric actuator is used to operate the valve remotely, allowing for automated control. What makes the valve explosion-proof is its housing and the actuator’s design, which are built to withstand high pressure and avoid sparking or igniting any explosive gases in the vicinity.