In industries that deal with flammable, volatile, or hazardous substances, safety is paramount. One essential component that plays a crucial role in ensuring both safety and operational efficiency is the explosion-proof electric butterfly valve. These valves are specifically designed to prevent the risk of ignition in environments that are prone to explosions, all while providing precise control over fluid and gas flow. As the demand for high-quality, durable valves continues to rise, manufacturers of explosion-proof electric butterfly valves have become increasingly vital in various industries, from chemical processing to oil and gas.

Understanding Explosion-proof Electric Butterfly Valves

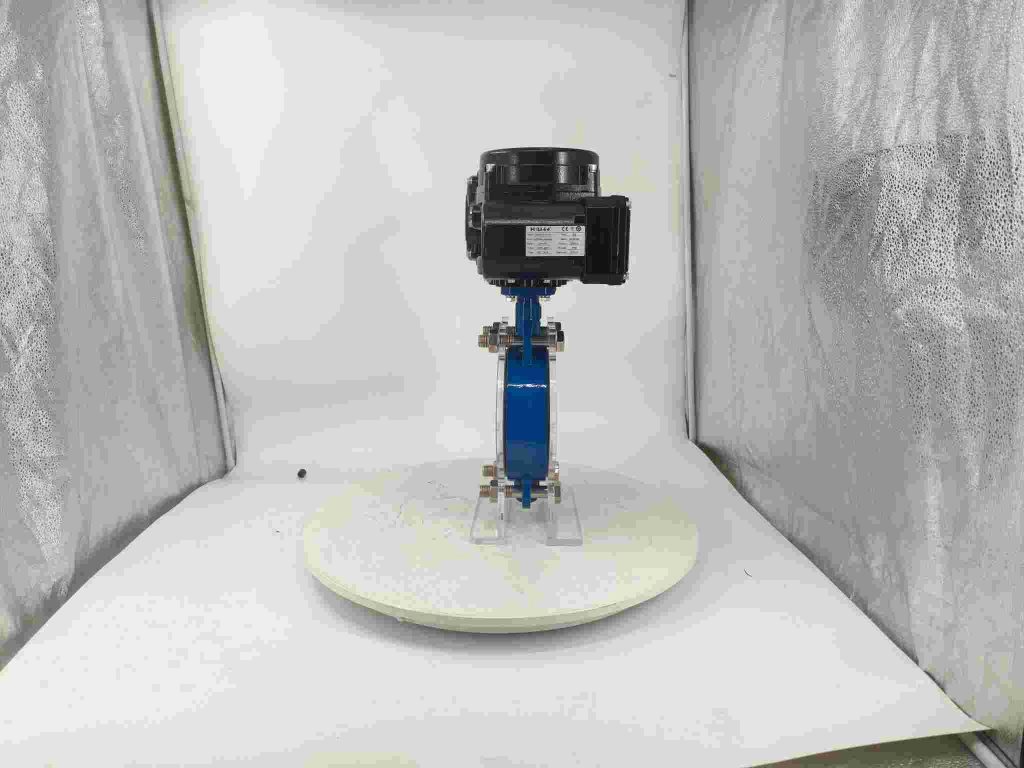

An explosion-proof electric butterfly valve is a type of quarter-turn valve that is powered by an electric actuator, which enables remote operation and automation of the valve. The primary function of this valve is to regulate the flow of fluids or gases in pipelines. However, what sets it apart from standard butterfly valves is its explosion-proof feature, which is achieved through the use of specially designed materials, construction, and sealing technologies. These valves are built to withstand the harsh conditions of explosive atmospheres, where the presence of flammable gases, vapors, or dust can pose a significant risk. To prevent any potential ignition that could lead to an explosion, explosion-proof valves are designed with components that do not produce sparks or heat, even when subjected to external factors like vibration, electrical surges, or mechanical stress. This makes them indispensable in industries where safety is of the utmost concern.