The Explosion-proof electric butterfly valve plays a critical role in modern industrial systems, particularly in sectors where volatile gases, chemicals, and other hazardous materials are handled. These valves are designed to offer reliable performance in environments where there is a potential risk of explosion or ignition. With the growing need for safety in industries such as oil and gas, chemical processing, and pharmaceuticals, the explosion-proof electric butterfly valve provides an essential solution to protect both equipment and personnel.

What is an Explosion-proof Electric Butterfly Valve?

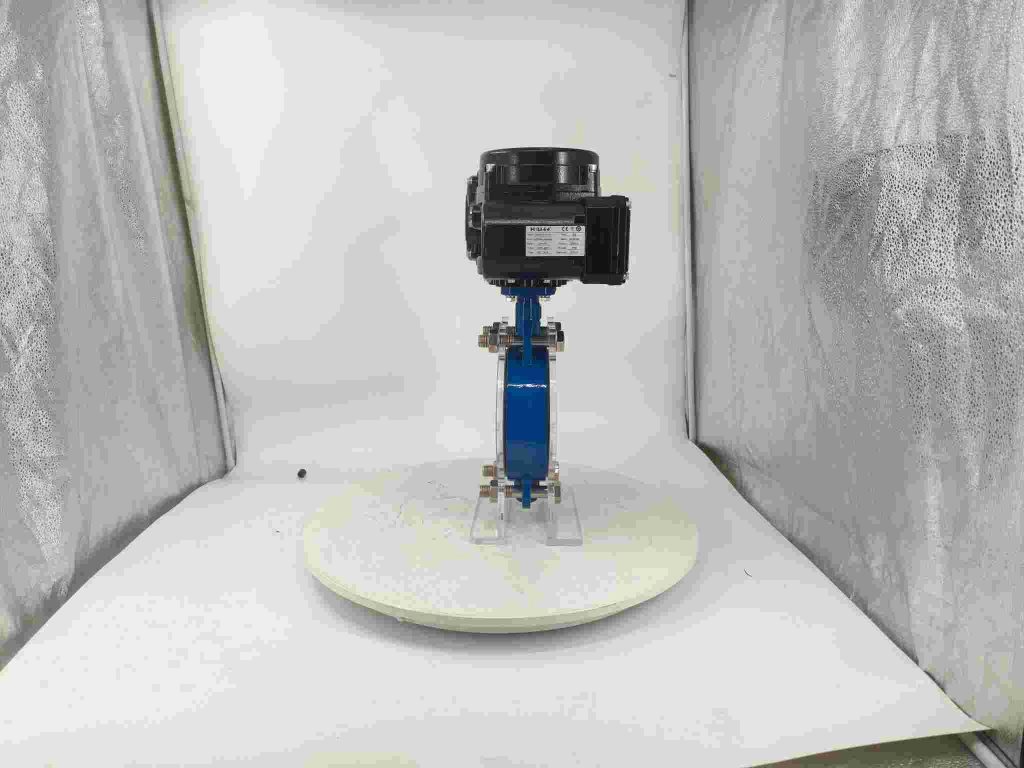

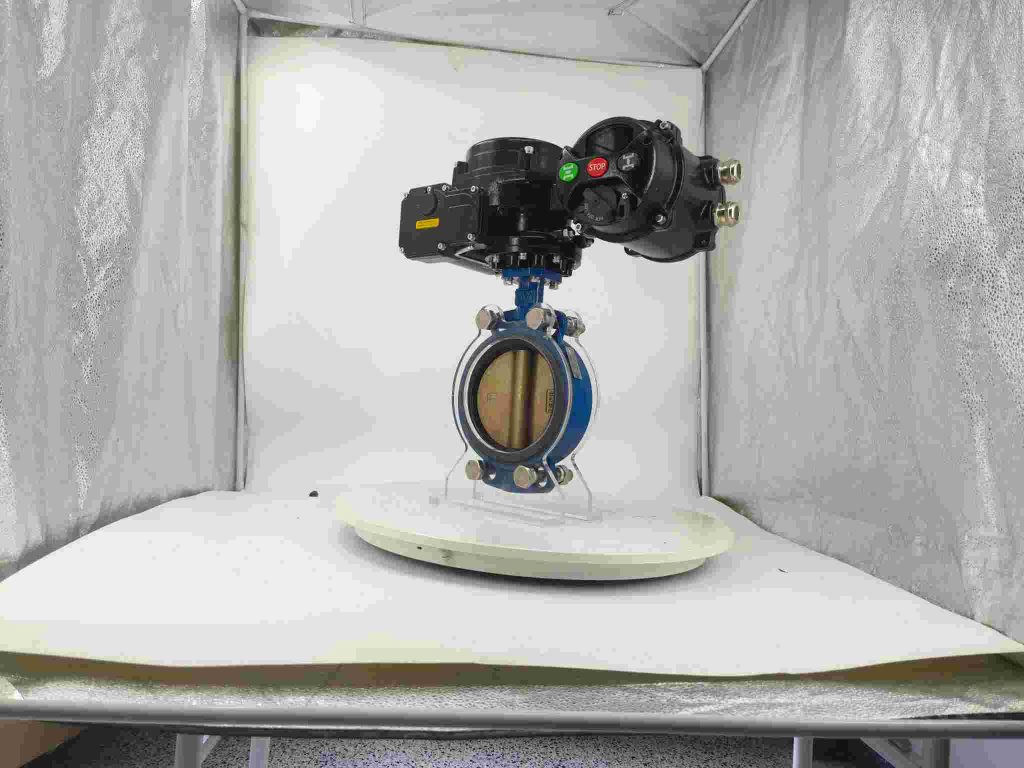

An Explosion-proof electric butterfly valve is a type of valve equipped with a motorized actuator, commonly used to regulate the flow of fluids in pipelines. The main distinguishing feature of this valve is its explosion-proof design, which ensures that it remains operational and safe even in hazardous environments where flammable gases, vapors, or dust are present. The valve’s butterfly disc rotates within a housing, opening or closing the flow path, while the electric actuator is used for automated control. Explosion-proof electric butterfly valves are built to meet strict safety standards, such as those specified by the International Electrotechnical Commission (IEC) and the National Fire Protection Association (NFPA). These standards ensure that the valve’s components, including the actuator and housing, are designed to withstand high pressure, temperature extremes, and potential explosive atmospheres.