In industrial processes where hazardous substances, high pressures, or extreme temperatures are common, safety is a paramount concern. To address these challenges, the explosion-proof electric butterfly valve has become a crucial component in maintaining system integrity and ensuring smooth operations. These valves are designed to regulate the flow of liquids or gases while preventing sparks or overheating that could lead to explosions, making them an essential part of any industry dealing with volatile environments.

What is an Explosion-proof Electric Butterfly Valve?

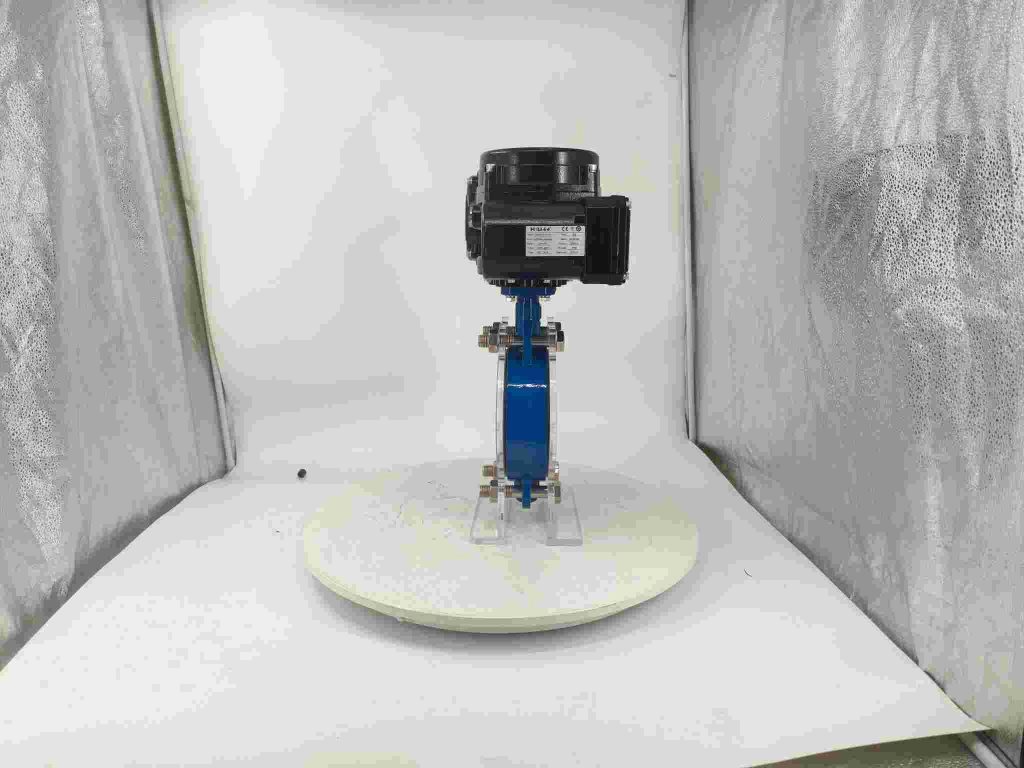

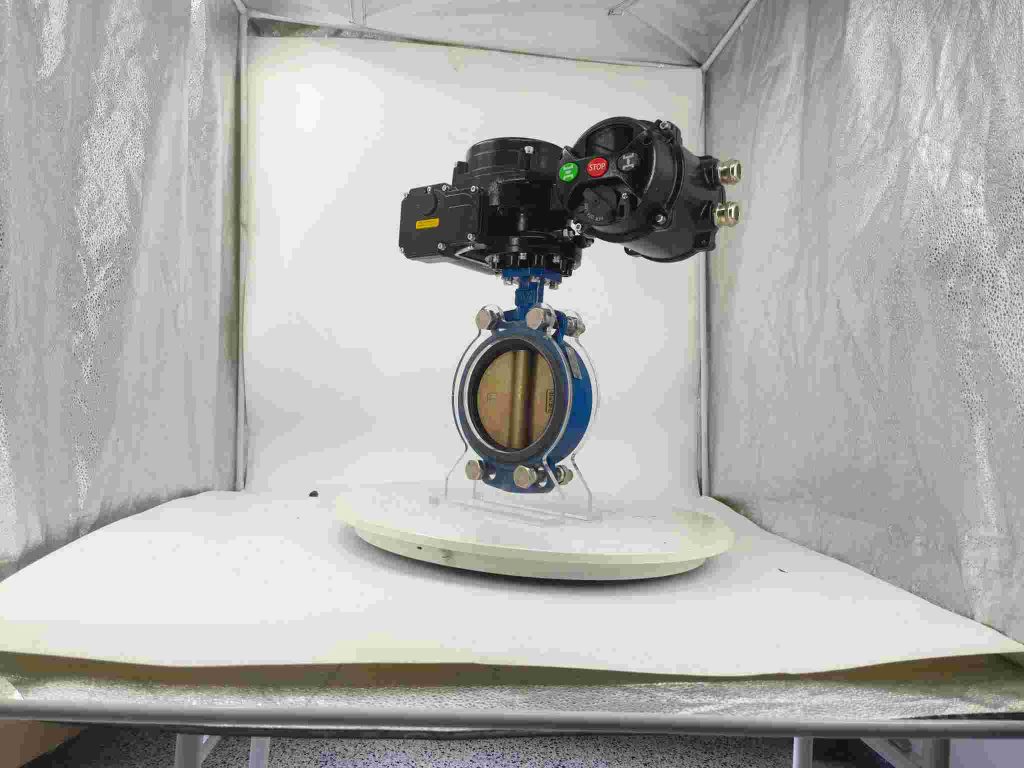

An explosion-proof electric butterfly valve combines two key features: an explosion-proof design and the precision control of an electric actuator. The butterfly valve itself consists of a disc that rotates within a pipe to control the flow of fluid. It is often used in applications where space is limited and quick control of flow is necessary. The electric actuator allows for automated operation, providing accurate and efficient control over the valve’s opening and closing. The “explosion-proof” aspect refers to the valve’s construction, which is specifically designed to prevent the ignition of flammable substances in environments where the risk of explosion is high. These valves are constructed using special materials and protective casings to ensure they can withstand harsh conditions without causing sparks or other forms of ignition. This makes them suitable for use in industries such as chemical processing, oil and gas, mining, and pharmaceutical manufacturing, where explosive gases or dust might be present.