In industrial processes, controlling the flow of liquids or gases is critical, especially in hazardous environments where the potential for explosions or fire is high. The explosion-proof electric butterfly valve is a crucial component designed to meet these specific needs. It combines the efficient flow control of a butterfly valve with the safety features required to prevent ignition in explosive atmospheres. In this article, we will explore the importance, design, and applications of explosion-proof electric butterfly valves, emphasizing their role in ensuring safety and operational efficiency in industries dealing with volatile substances.

What is an Explosion-Proof Electric Butterfly Valve?

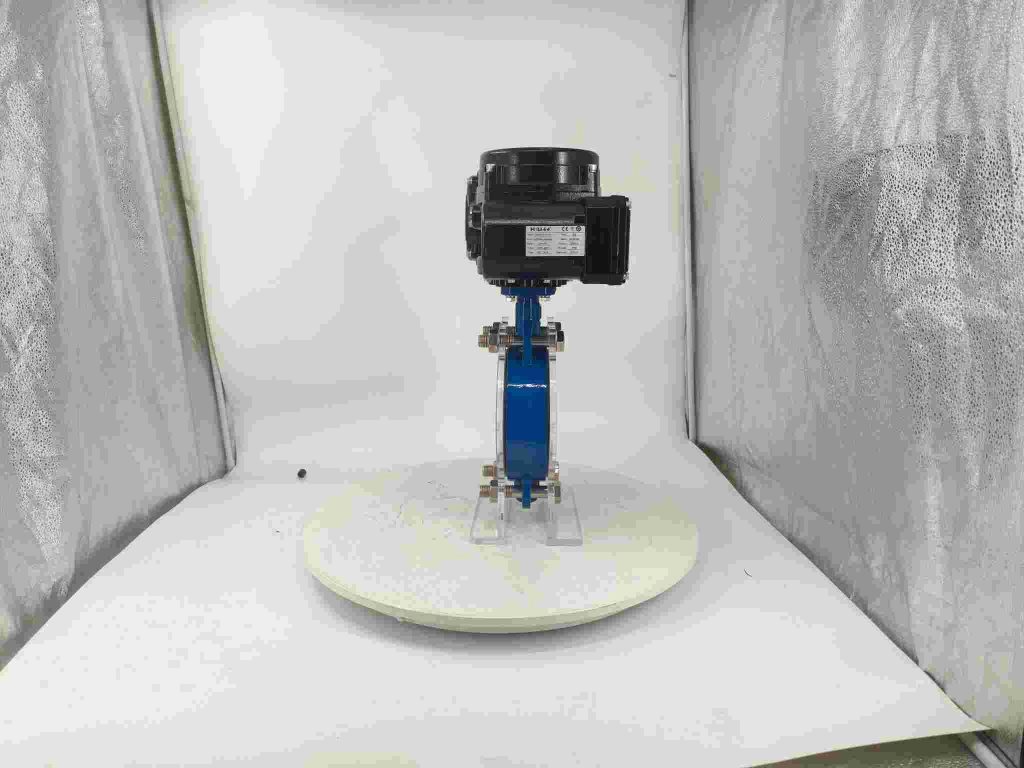

An explosion-proof electric butterfly valve is a type of flow control valve that incorporates an electric actuator with explosion-proof capabilities, designed for use in environments where there is a risk of gas or dust explosions. The valve itself is a quarter-turn valve, typically featuring a disc that rotates to regulate flow. The electric actuator allows for remote or automated operation, making it suitable for modern, highly automated industrial systems. The explosion-proof design ensures that the valve and actuator will not become sources of ignition, preventing sparks or heat from triggering an explosion.