In industrial settings where explosive gases or flammable materials are present, safety is paramount. One critical component designed to address such challenges is the explosion-proof electric butterfly valve. This specialized valve combines the functionality of a butterfly valve with electric actuation and explosion-proof features, making it essential for maintaining operational integrity in hazardous environments.

The explosion-proof electric butterfly valve is engineered to provide reliable control over the flow of gases and liquids in environments where there is a risk of explosion. Its design ensures that it can operate safely and efficiently even under extreme conditions, protecting both equipment and personnel from potential hazards.

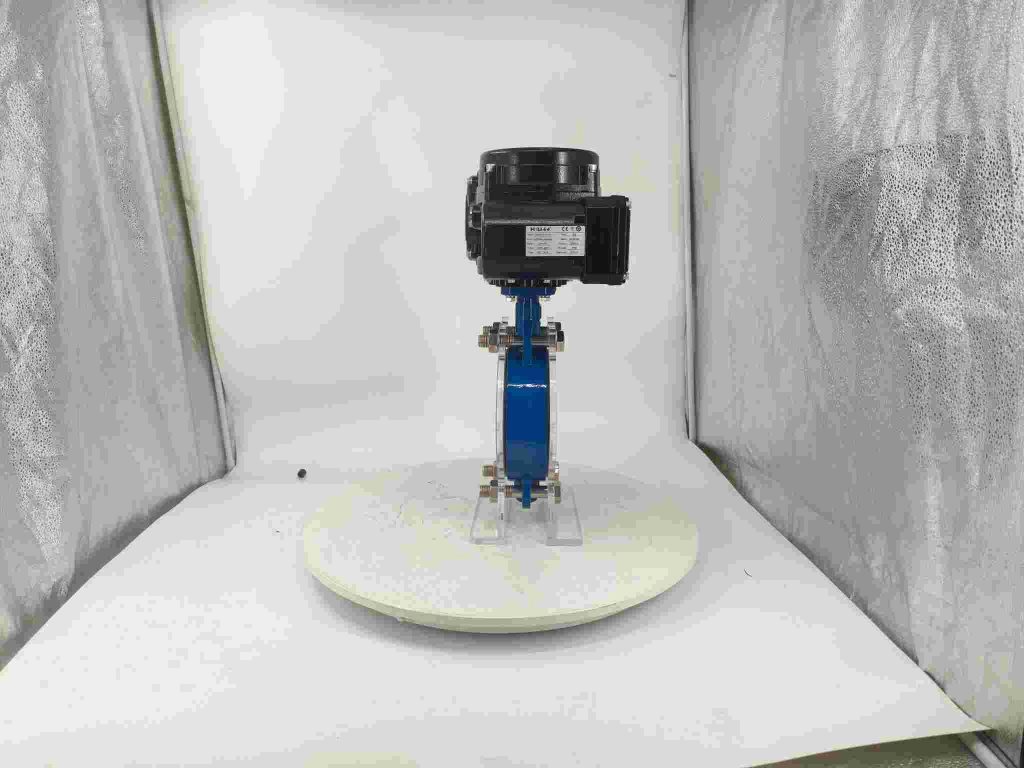

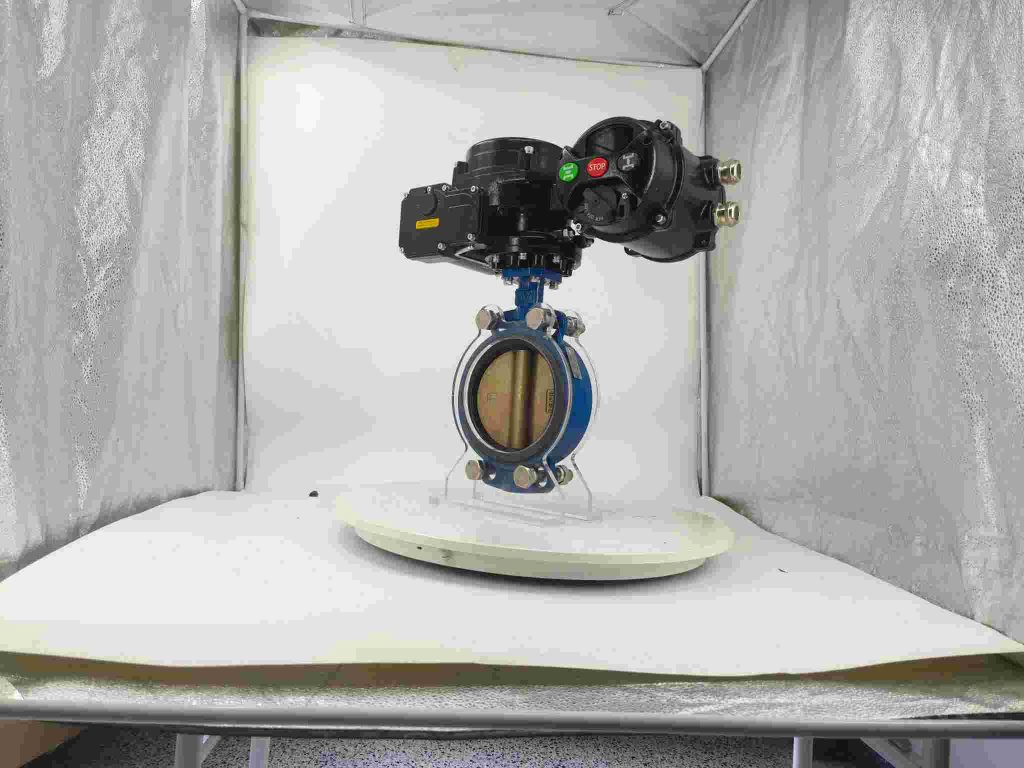

Design and Construction The valve’s body is typically constructed from durable materials such as stainless steel or cast iron, which are resistant to high pressure and corrosive substances. The electric actuator is housed within an explosion-proof enclosure, which prevents any electrical sparks from igniting the surrounding volatile atmosphere. This enclosure is built to meet rigorous international standards, such as those set by the ATEX or IECEx certifications, which ensure that the valve performs reliably in hazardous locations. The butterfly valve itself features a disc that rotates to control the flow of fluid. This disc is positioned within the valve body, and its rotation is precisely controlled by the electric actuator. This design allows for quick and accurate regulation of flow rates, making it suitable for applications where precision is crucial.