In industries such as oil and gas, chemicals, and mining, the need for safety is paramount. Hazardous environments often contain explosive gases, dust, or flammable materials, making equipment safety a critical concern. The Explosion-proof electric butterfly valve is designed to meet these high standards, combining advanced valve technology with explosion-proof capabilities. This article explores the features, applications, and advantages of these crucial devices.

Understanding the Explosion-proof Electric Butterfly Valve

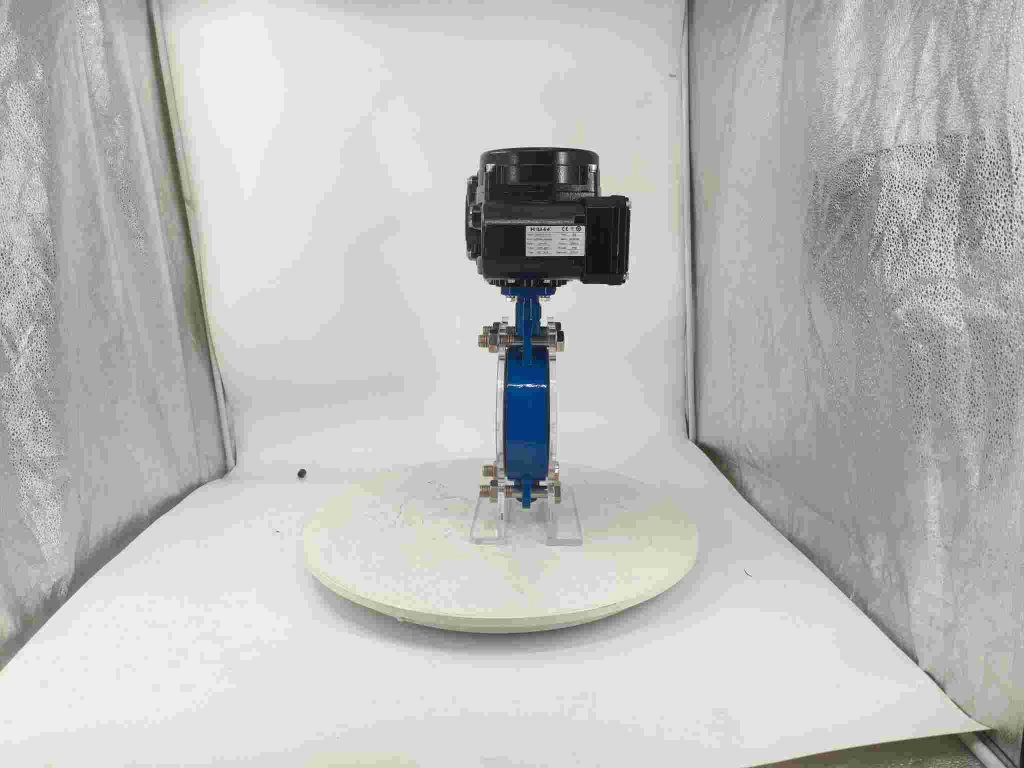

A butterfly valve is a quarter-turn valve with a rotating disc that controls the flow of fluids. It’s commonly used in large pipelines due to its compact design, low weight, and ability to handle large volumes of flow with minimal resistance. The electric butterfly valve, on the other hand, uses an electric actuator to automate the valve’s operation, allowing for remote control and enhancing the efficiency of processes. The Explosion-proof electric butterfly valve merges these technologies with the added protection of explosion-proof features, designed specifically for environments where flammable substances are present. This valve type is equipped with special electrical and mechanical safety mechanisms to prevent sparks or overheating from igniting hazardous gases or materials in the surrounding atmosphere.