In industries that deal with volatile chemicals, gases, and flammable materials, the risk of explosion is a constant concern. To mitigate this danger and maintain smooth operations, specialized equipment is necessary. One such vital component is the explosion-proof electric butterfly valve. These valves are designed to control the flow of fluids, gases, and slurries in pipelines while ensuring safety in environments where explosive atmospheres are a risk. This article explores the design, features, applications, and safety standards associated with explosion-proof electric butterfly valves.

What is an Explosion-proof Electric Butterfly Valve?

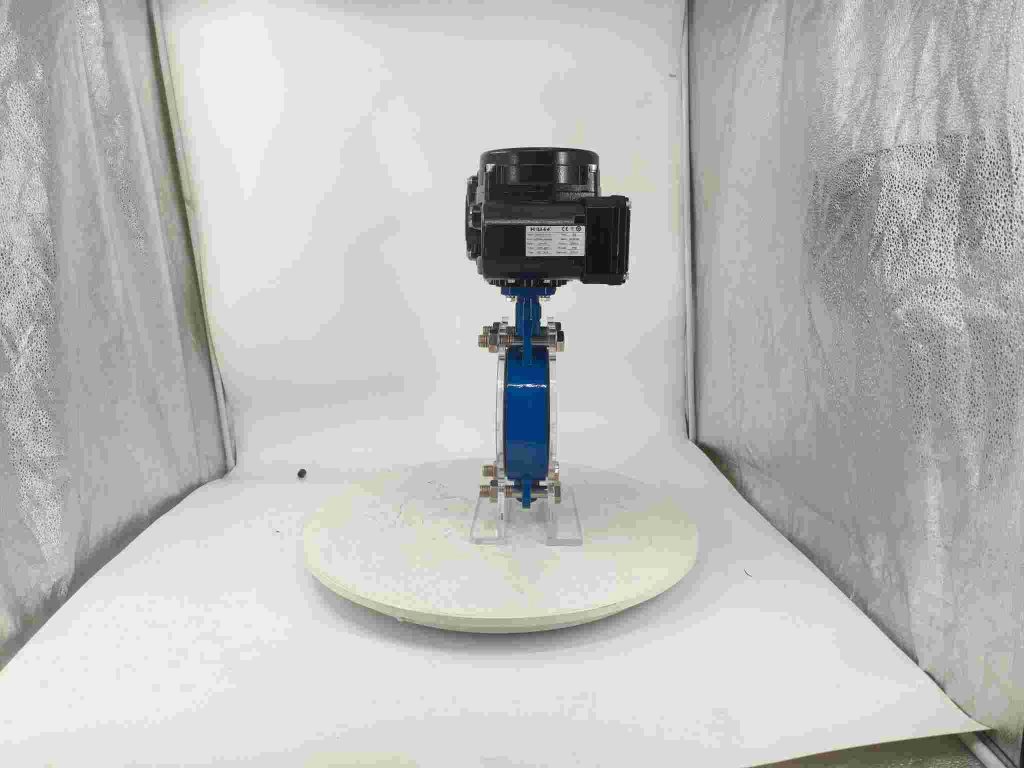

An explosion-proof electric butterfly valve is a critical piece of equipment used in industries prone to explosive hazards, such as oil and gas, chemical processing, and pharmaceuticals. These valves consist of a circular disc that rotates within the pipeline to regulate fluid or gas flow. The unique aspect of these valves lies in their explosion-proof construction, which prevents sparks or heat generated by the actuator from igniting surrounding explosive atmospheres. The electric actuator provides precise control over the valve’s opening and closing, eliminating the need for manual operation. These valves are often equipped with electric motors, making them highly reliable in automated systems and remote operations. They are also highly durable, built to withstand challenging environments and to prevent catastrophic accidents that could result from an explosion.