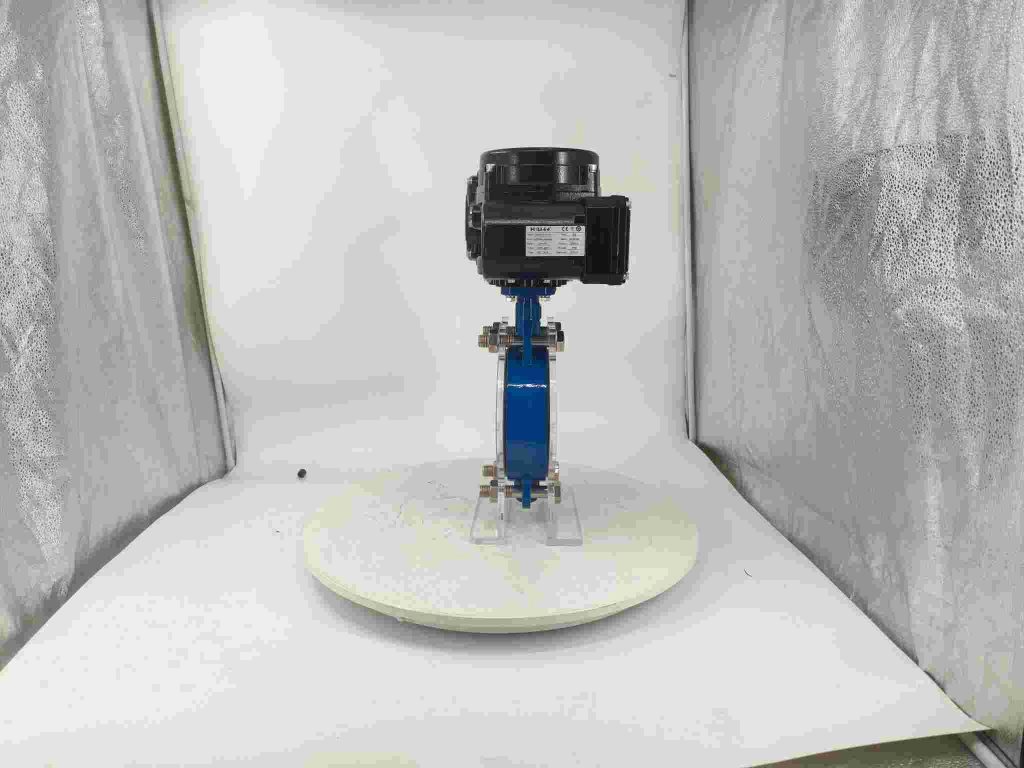

The Explosion-proof electric butterfly valve is a specialized valve designed to safely control the flow of fluids in potentially hazardous environments where the risk of explosion is present. This advanced valve combines the characteristics of an electric actuator and a butterfly valve, offering a highly efficient solution for industries dealing with explosive gases, flammable liquids, or combustible dust. Its ability to function in dangerous environments while ensuring safety makes it an essential component in various sectors such as chemical processing, oil and gas, and pharmaceuticals.

Introduction to Explosion-proof Electric Butterfly Valves

Explosion-proof valves are essential components in industries where explosive substances, volatile chemicals, or dangerous gases are handled. These valves are designed to prevent the ignition of potentially explosive materials within the valve’s system, ensuring that both the equipment and personnel remain safe in such high-risk environments. The Explosion-proof electric butterfly valve is an amalgamation of two primary technologies: the butterfly valve design and the electric actuator. The butterfly valve, with its disc-shaped closure element, regulates the flow of materials by rotating the valve disk. When paired with an electric actuator, it can be operated remotely, making it a suitable choice for automated industrial systems. The addition of explosion-proof capabilities allows this valve to operate safely in hazardous zones without posing the risk of triggering a fire or explosion.