In the realm of modern manufacturing, metal stamping has emerged as a cornerstone process, producing intricate components used across a multitude of industries. Metal stamping parts manufacturers play a pivotal role in shaping our world, crafting everything from automobile components to household appliances. This article delves into the realm of metal stamping, shedding light on its significance and the key players driving this industry.

The Art of Metal Stamping

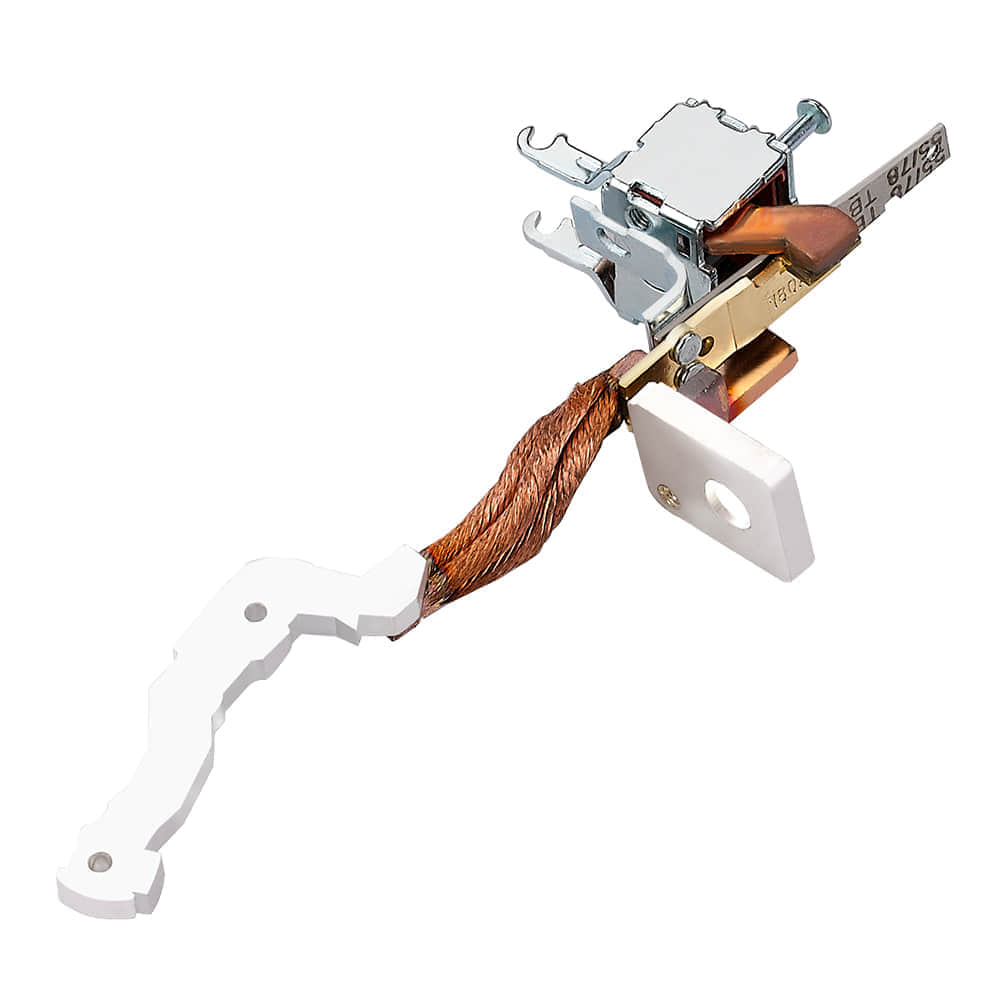

Metal stamping is a manufacturing process that involves cutting, shaping, and forming metal sheets into various designs and sizes. It’s a versatile technique that employs both traditional and advanced methods to create parts that meet stringent quality and precision standards. The process begins with designing the stamping die, a specialized tool used to cut and shape the metal. This die is then pressed onto the metal sheet with immense force, resulting in the desired shape. The Significance of Metal Stamping Parts Manufacturers Metal stamping parts manufacturers are instrumental in producing components used in countless applications. From small electrical connectors to complex automotive parts, the range of products manufactured through this process is vast. The automobile industry, for instance, heavily relies on metal stamping for producing parts like fenders, panels, and engine components. Similarly, the aerospace sector benefits from precision-stamped parts used in aircraft construction. Key Characteristics of Reliable Manufacturers Technological Expertise:Reputable manufacturers stay abreast of technological advancements in stamping machinery and techniques. This enables them to offer innovative solutions and maintain a competitive edge. Material Knowledge:Different projects demand different materials. Reliable manufacturers possess deep insights into various metals, enabling them to suggest the most suitable material for a specific application. Quality Assurance:Stringent quality checks are imperative in metal stamping. Established manufacturers have robust quality control processes in place to ensure each product meets or exceeds the required standards. Customization Capabilities:Every industry has unique requirements. Top manufacturers offer customization options, tailoring their processes to meet the distinct needs of each client. Collaborative Approach:Effective communication between the manufacturer and the client is vital. Reputable manufacturers maintain an open line of dialogue, involving the client at every stage from design to production. Navigating Technological Advancements As technology continues to advance, so does the metal stamping industry. Computer Numerical Control (CNC) systems, for instance, have revolutionized the precision and efficiency of the process. These systems allow for intricate designs and repeatable accuracy, minimizing errors and wastage. Challenges and Future Prospects While metal stamping offers remarkable benefits, it’s not without challenges. Complex designs, material limitations, and cost considerations can pose obstacles. However, manufacturers are actively addressing these challenges through ongoing research and development. The integration of AI and machine learning, for example, aids in predicting and preventing defects, enhancing overall quality. Looking ahead, the future of metal stamping parts manufacturing appears promising. As industries continue to evolve, the demand for intricate and high-quality metal components will persist. Manufacturers that embrace automation, refine their techniques, and prioritize sustainability will likely thrive in this dynamic landscape. In Conclusion Metal stamping parts manufacturers play a crucial role in shaping the products we rely on daily. Their expertise, coupled with technological advancements, drives the production of components across industries. As the manufacturing landscape continues to transform, the art of metal stamping will undoubtedly remain a cornerstone, meeting the ever-growing demand for precision-engineered metal parts.