Metal stamping, a fundamental process in the manufacturing industry, plays a pivotal role in shaping various products that we encounter daily. From intricate electronic components to robust automotive parts, metal stamping manufacturers are the unsung heroes behind the scenes, turning sheets of metal into precise and functional components. In this article, we delve into the world of metal stamping parts manufacturers, exploring their significance, processes, and impact on modern production.

The Significance of Metal Stamping Parts Manufacturers

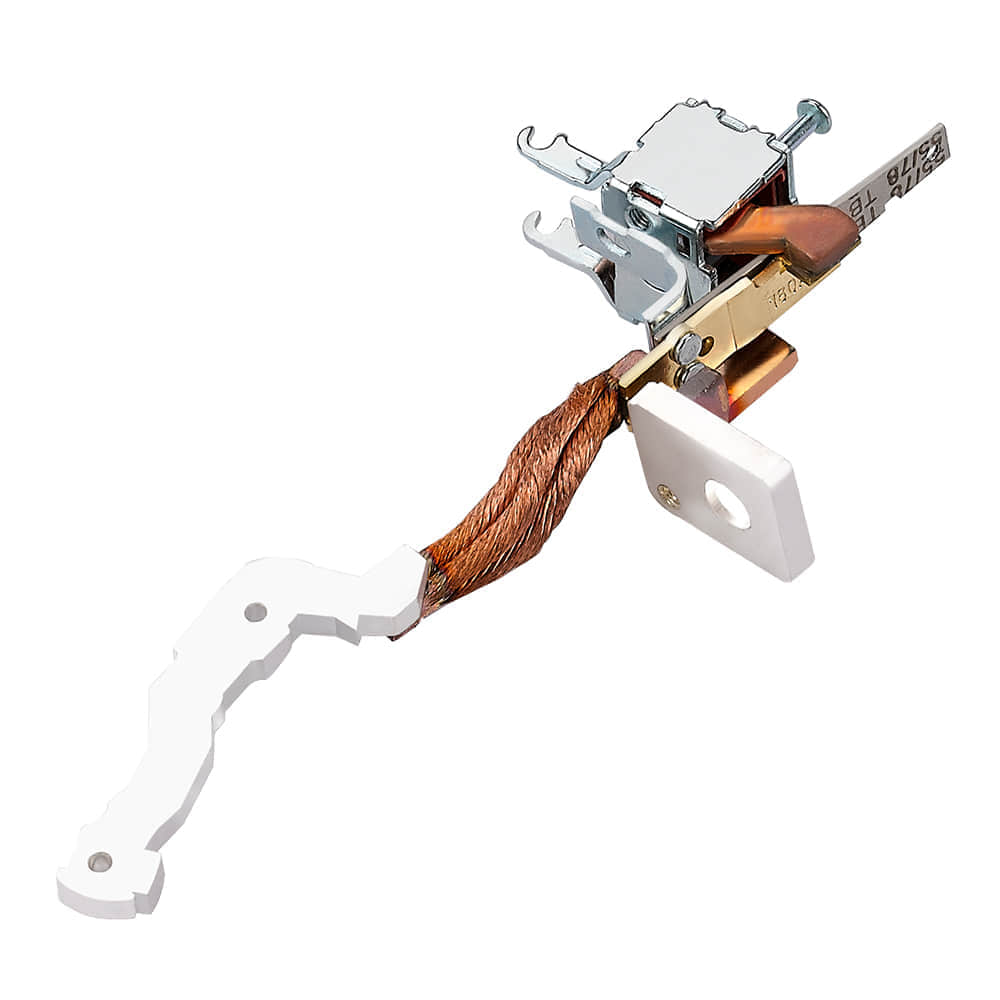

Metal stamping is a manufacturing technique that involves cutting, bending, and shaping metal sheets to create parts and components. These parts serve as integral building blocks for industries like automotive, aerospace, electronics, and appliances. Metal stamping parts manufacturers are at the heart of this process, utilizing advanced machinery and technology to transform raw materials into usable components that meet strict quality standards. The Metal Stamping Process The metal stamping process is a fusion of creativity, engineering, and precision. It begins with the creation of a custom tool and die, which outlines the desired shape and features of the component. This die is then pressed onto a metal sheet, cutting the material into the desired shape. Additional processes like bending, embossing, and coining can be applied to achieve the final form. Manufacturers employ various stamping methods, including progressive, transfer, and tandem stamping, based on the complexity of the component and the required volume. Progressive stamping involves a series of operations performed in sequence, while transfer stamping moves the component between different stations for various operations. Tandem stamping utilizes multiple presses in a row to perform operations simultaneously, increasing efficiency for high-volume production. Innovation and Technology The realm of metal stamping is not impervious to technological advancements. Modern metal stamping parts manufacturers harness the power of computer-aided design (CAD) and computer-aided manufacturing (CAM) software to design intricate tooling with unparalleled accuracy. Simulation software allows them to visualize and optimize the stamping process before physical production, reducing the likelihood of defects and material wastage. Additionally, the incorporation of robotics and automation has revolutionized metal stamping. Automated material handling, die changes, and quality inspections have streamlined production, resulting in faster turnaround times and enhanced precision. These innovations have not only improved efficiency but also reduced the physical toll on workers, making the manufacturing environment safer and more ergonomic. Quality Control and Compliance Metal stamping parts manufacturers adhere to stringent quality control measures to ensure the components they produce are reliable and consistent. Advanced inspection techniques such as computer vision systems, coordinate measuring machines (CMM), and non-destructive testing are employed to identify even the slightest deviations from specifications. This dedication to quality guarantees that the stamped parts integrate seamlessly into the final product, whether it’s a consumer electronic device or a critical automotive component. Environmental Considerations As industries focus more on sustainability, metal stamping parts manufacturers are also adopting eco-friendly practices. The efficient use of materials, recycling of scrap metal, and implementation of energy-efficient machinery contribute to reducing the environmental footprint of the manufacturing process. By minimizing waste and optimizing resource utilization, these manufacturers are aligning with global efforts toward a greener future. Conclusion Metal stamping parts manufacturers are the backbone of modern manufacturing, shaping the products that drive our world. Their innovative processes, integration of technology, commitment to quality, and environmental consciousness collectively make them key players in various industries. As technology continues to advance and industries evolve, these manufacturers will remain at the forefront of innovation, driving progress and enabling the creation of products that shape our future.