Metal stamping parts are a crucial component of modern manufacturing processes, playing a significant role in various industries, from automotive to electronics. This article delves into the world of metal stamping parts, examining their importance, manufacturing processes, and diverse applications.

Understanding Metal Stamping Parts

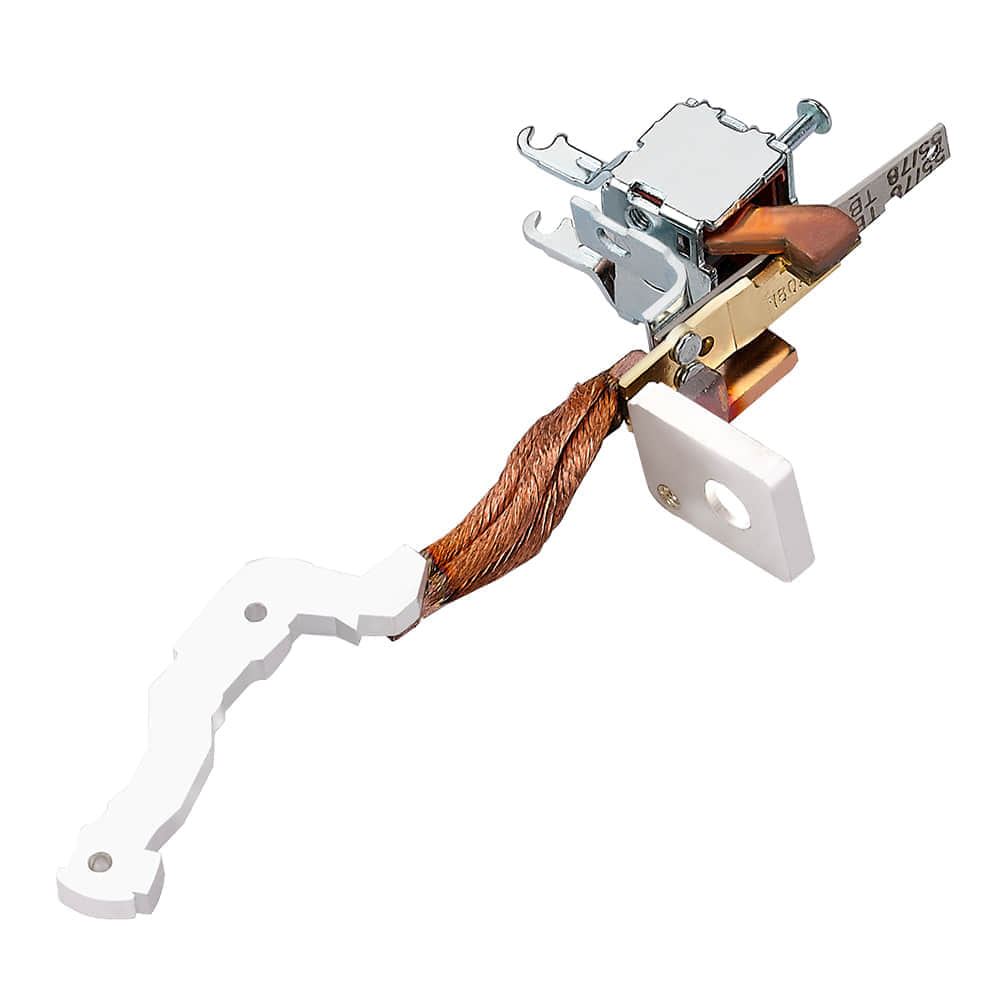

Metal stamping is a manufacturing process that involves shaping flat sheets of metal into desired forms using dies and presses. This versatile method produces parts with precision and consistency, making it an integral part of many industries. The primary materials used in metal stamping include steel, aluminum, copper, and stainless steel, each selected for its unique properties and application requirements. The Manufacturing Process The manufacturing of metal stamping parts involves several key steps: Material Selection:The choice of material is crucial, as it determines the part’s strength, durability, and conductivity. Engineers carefully select the appropriate material based on the desired application. Design and Tooling:Engineers create detailed designs for the metal stamping part, including die specifications. These designs guide the construction of the stamping dies, which are specialized tools used to shape the metal. Blanking:This initial step involves cutting the metal sheet into the desired shape, creating what is known as a blank. The blank is typically larger than the final part to account for material stretching during the stamping process. Stamping:The blank is placed into the stamping press, and the die exerts immense force to shape the metal into the desired form. This process may involve several stamping operations to achieve intricate shapes. Secondary Operations:After stamping, secondary operations like trimming, deburring, and welding may be necessary to refine the part’s appearance and functionality. Quality Control:Stringent quality checks ensure that each part meets the required specifications. This step is critical to guarantee the part’s reliability and safety. Applications of Metal Stamping Parts Metal stamping parts find applications in various industries: Automotive Industry:Metal stamping is widely used in automotive manufacturing to produce components such as body panels, chassis parts, and engine components. These parts require high precision and durability to ensure vehicle safety and performance. Electronics:Metal stamping is crucial in the production of electronic components like connectors, terminals, and shielding. These parts demand precision and reliability for seamless electrical connections and signal integrity. Aerospace:Aerospace manufacturers rely on metal stamping to create lightweight, high-strength components for aircraft and spacecraft. These parts must withstand extreme conditions and meet strict safety standards. Appliances:Metal stamping parts are commonly used in household appliances, such as washing machine drums, refrigerator components, and microwave oven enclosures, where durability and precision are paramount. Medical Devices:Metal stamping is integral to the medical device industry, producing items like surgical instruments, implantable devices, and diagnostic equipment, where precision and biocompatibility are essential. Construction:Metal stamping contributes to the construction sector by producing structural components, fasteners, and hardware that ensure the integrity and safety of buildings and infrastructure. Conclusion In conclusion, metal stamping parts are the unsung heroes of modern manufacturing. Their versatility, precision, and durability make them indispensable in a wide range of industries. As technology advances, metal stamping processes continue to evolve, leading to even more innovative applications and contributions to various sectors. Understanding the significance of metal stamping parts sheds light on the intricate world of manufacturing that drives our modern world.