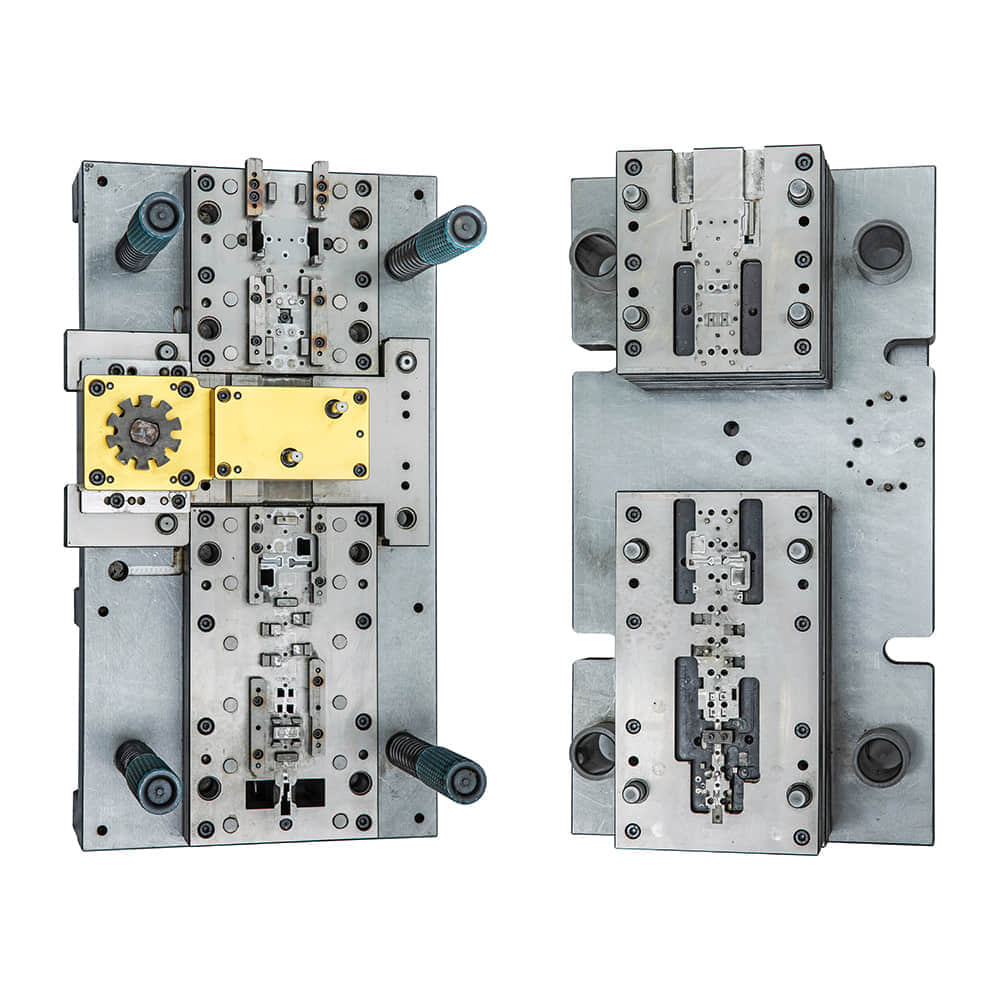

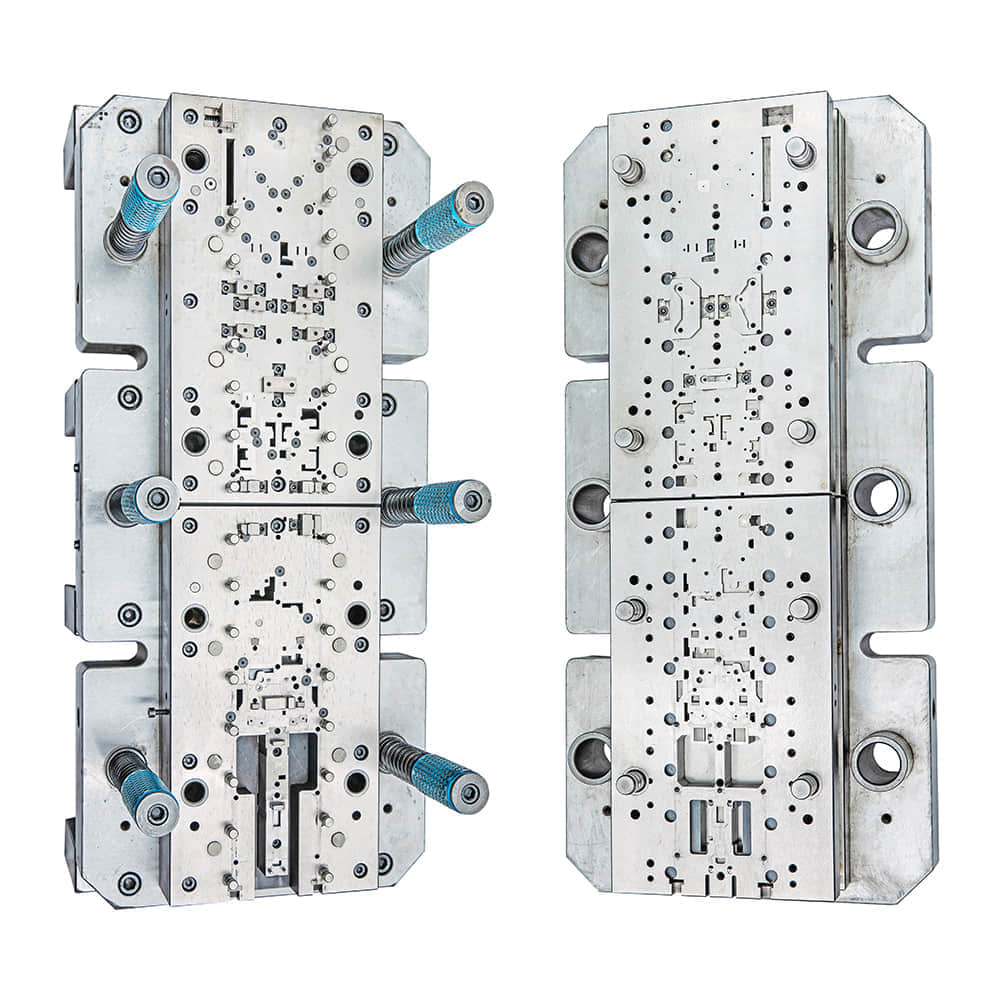

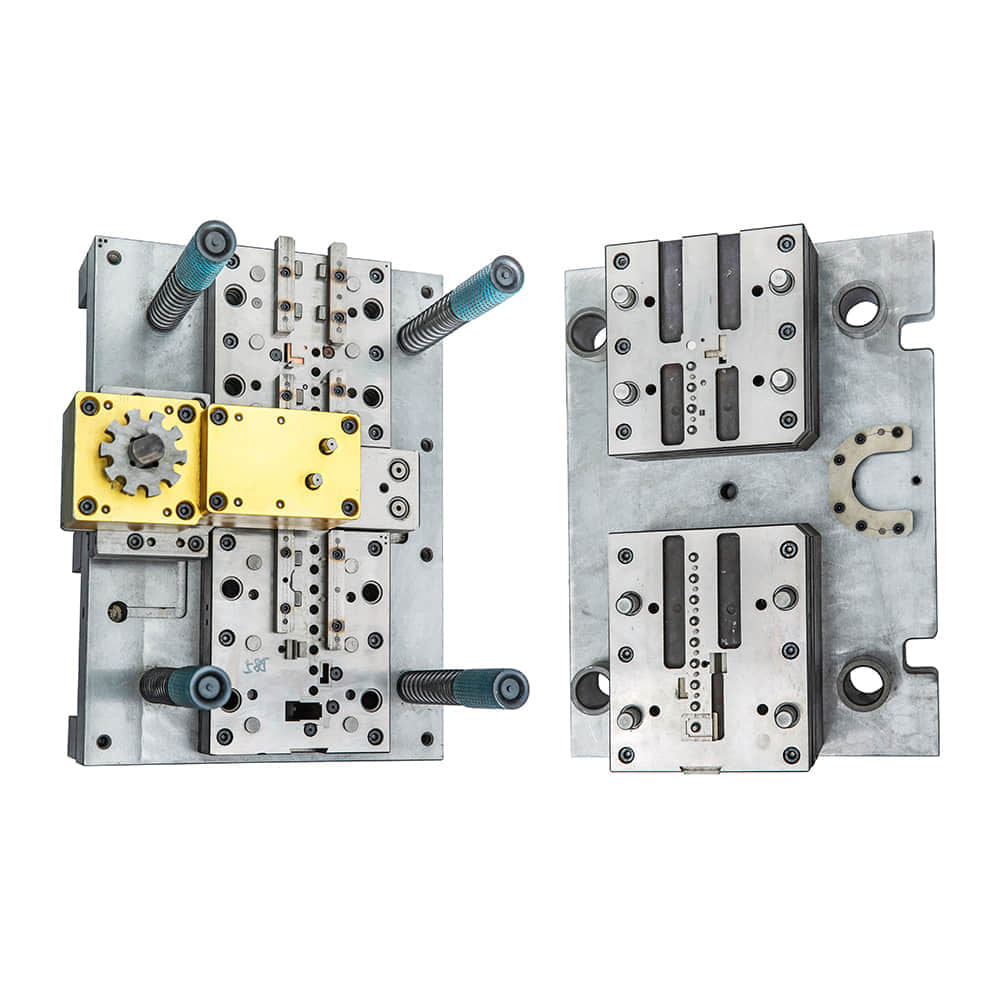

In the realm of precision engineering and manufacturing, Metal Stamping Die OEM Manufacturers play a pivotal role in shaping industries and transforming raw materials into intricate products. With a rich history and an eye for innovation, these manufacturers have revolutionized the way products are created across various sectors.

Introduction

Metal Stamping Die Original Equipment Manufacturer (OEM) companies are at the forefront of modern manufacturing. They specialize in crafting custom-made tools, dies, and molds used in metal stamping processes. These processes involve cutting, shaping, and transforming sheets of metal into precise components that serve as building blocks for countless products. Precision Engineering and Innovation At the heart of every Metal Stamping Die OEM Manufacturer lies precision engineering. These manufacturers utilize advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to create intricate designs that guide the metal stamping process. The synergy of human expertise and technological innovation results in dies that can produce components with micrometer-level accuracy. Moreover, Metal Stamping Die OEM Manufacturers are not just limited to traditional manufacturing methods. They constantly explore new materials, techniques, and processes to improve efficiency, reduce waste, and enhance the quality of stamped components. This commitment to innovation drives industries forward and enables the creation of products that were once deemed unattainable. Customization and Versatility One of the defining features of Metal Stamping Die OEM Manufacturers is their ability to create custom solutions. Every product requires specific components, and these manufacturers tailor their dies to meet unique requirements. Whether it’s for the automotive, electronics, aerospace, or medical industry, Metal Stamping Die OEM Manufacturers produce dies that enable the consistent production of intricate parts at scale. Collaborative Partnerships Metal Stamping Die OEM Manufacturers don’t operate in isolation; they thrive on collaborative partnerships. These partnerships involve close interactions with clients to understand their needs, technical specifications, and production goals. The iterative feedback process ensures that the final product aligns with the client’s vision while adhering to the highest quality standards. Quality Assurance In the world of manufacturing, quality is non-negotiable. Metal Stamping Die OEM Manufacturers implement rigorous quality control measures at every stage of the production process. From material selection to die design and production, each step is scrutinized to minimize defects and maintain consistency. This dedication to quality has earned these manufacturers a reputation for reliability and excellence. Sustainability and Efficiency As industries shift towards more sustainable practices, Metal Stamping Die OEM Manufacturers are also embracing environmentally friendly initiatives. They employ techniques that minimize material wastage, optimize energy consumption, and reduce the overall carbon footprint. By prioritizing sustainability, these manufacturers contribute to the creation of a greener and more responsible manufacturing ecosystem. Global Impact The impact of Metal Stamping Die OEM Manufacturers extends far beyond their immediate production facilities. Their precision dies are integral to the production of a wide array of products that we encounter daily. From the chassis of automobiles to the tiniest electronic components, Metal Stamping Die OEM Manufacturers shape the modern world. Conclusion In the realm of manufacturing, Metal Stamping Die OEM Manufacturers hold a unique and indispensable position. Their commitment to precision, innovation, customization, and quality sets them apart as key players in various industries. As technology continues to advance, we can only anticipate that these manufacturers will push the boundaries of what’s possible, further propelling industries into the future.