In the realm of precision manufacturing, metal stamping dies play a pivotal role in shaping industries and products that touch our daily lives. These intricate tools are the unsung heroes behind the seamless production of countless metal components used in automobiles, electronics, appliances, and more. This article delves into the world of metal stamping die manufacturers, uncovering their significance, the manufacturing process, and the impact they have on various sectors.

The Significance of Metal Stamping Die Manufacturers

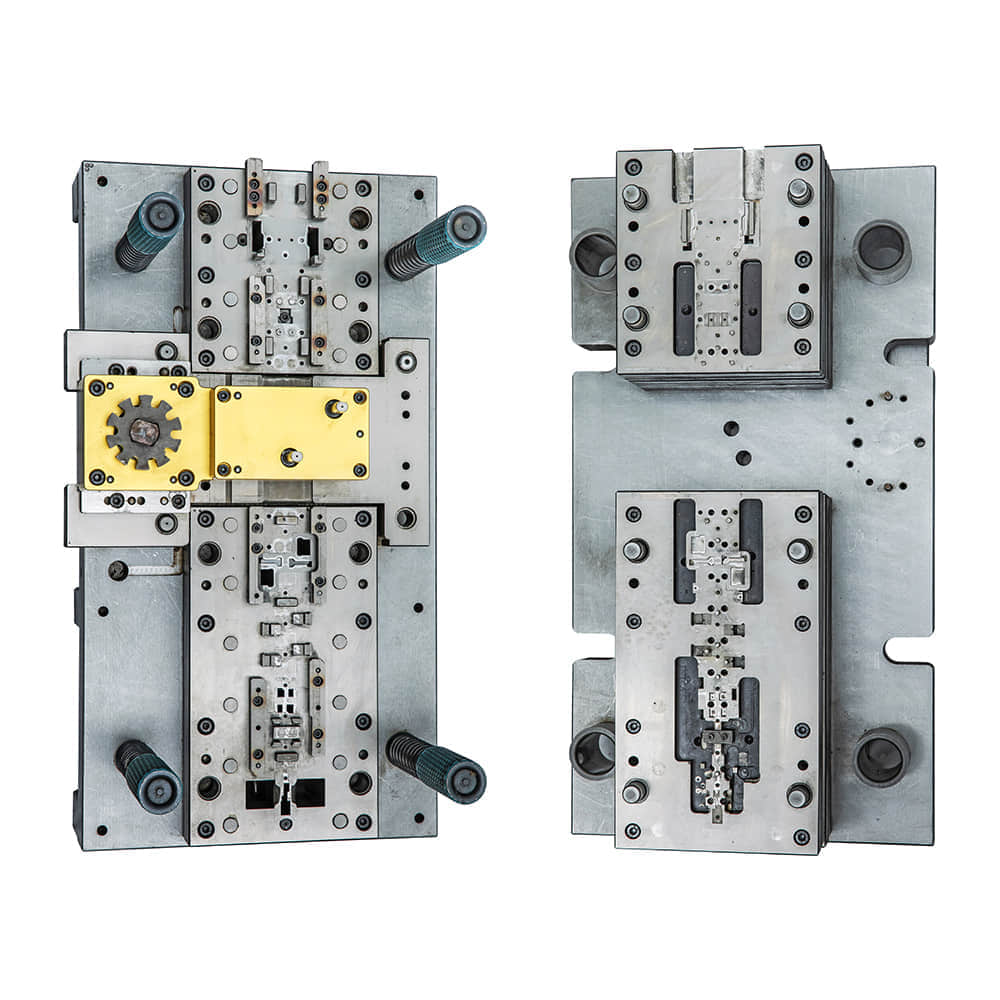

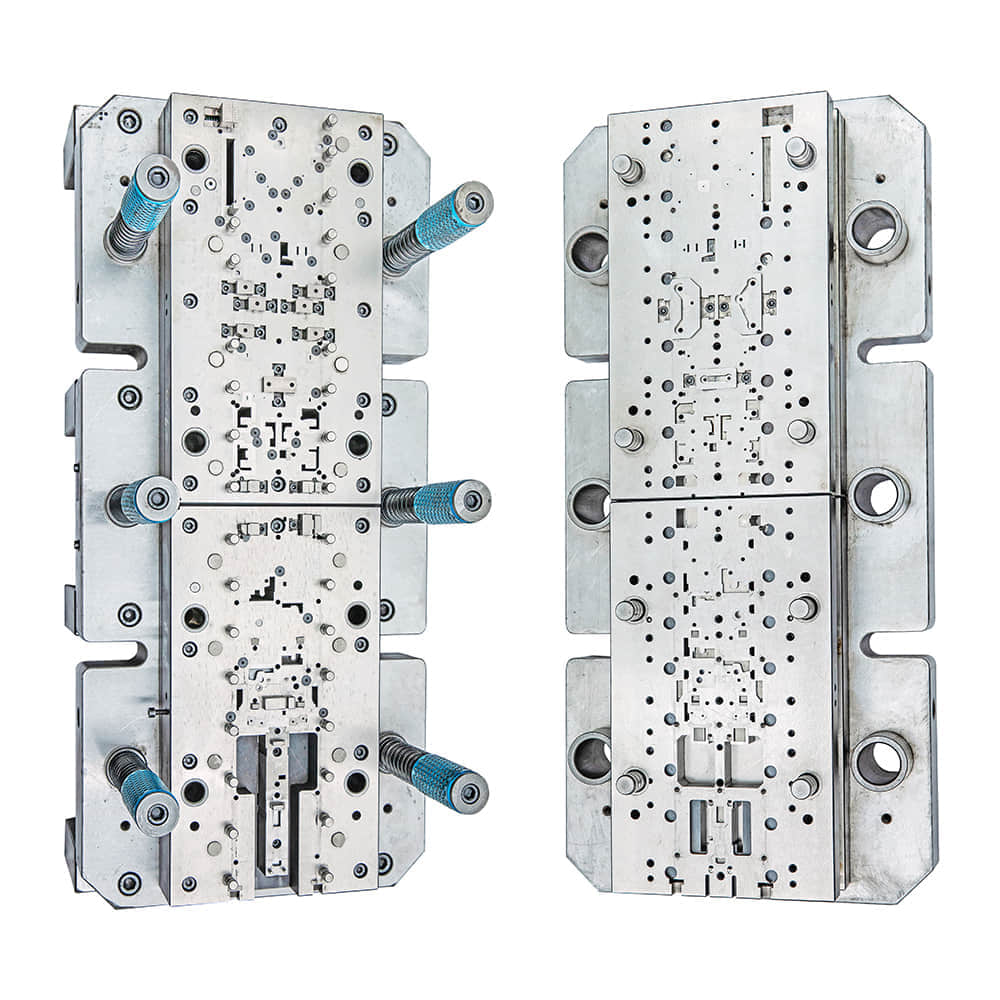

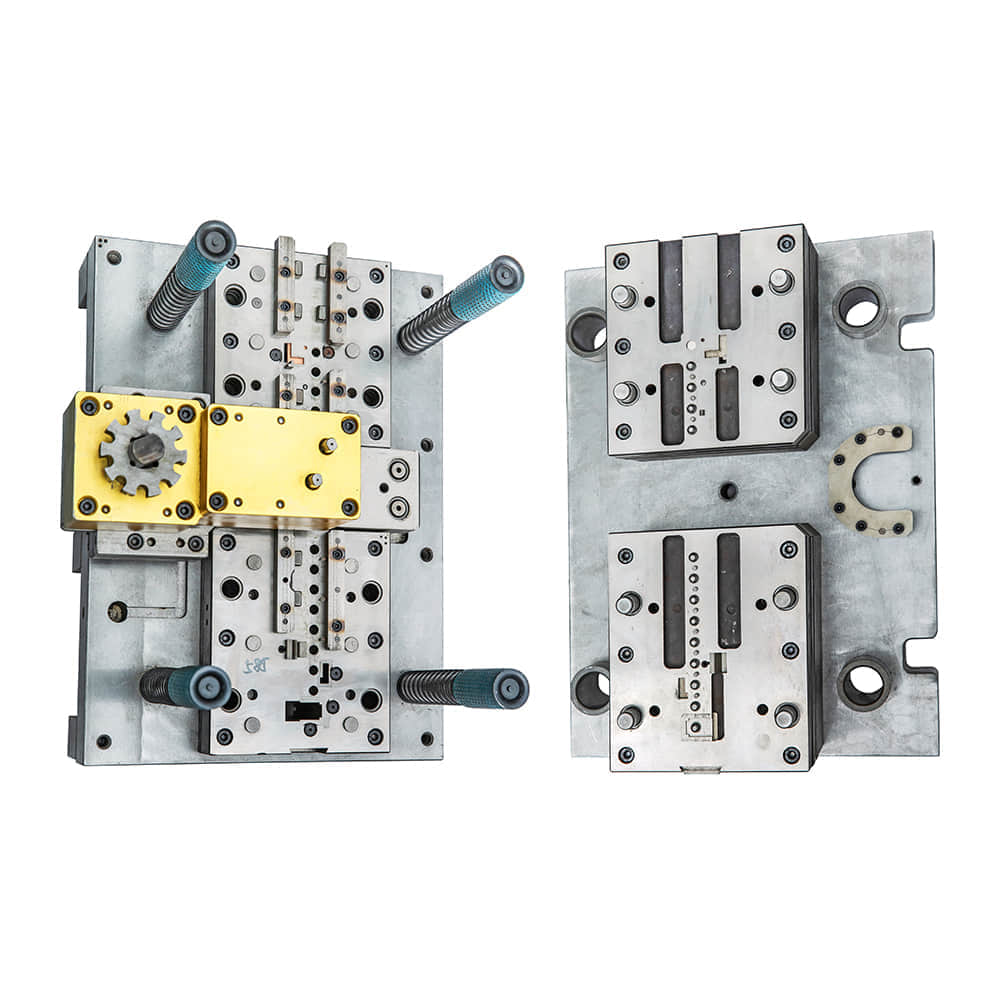

Metal stamping dies are specialized tools used to shape, cut, or form metal sheets into desired shapes and sizes. They are crucial for maintaining consistency, precision, and efficiency in mass production. These dies come in various forms, including progressive dies, transfer dies, and single-stage dies, each serving a specific purpose in the manufacturing process. The Manufacturing Process Manufacturing metal stamping dies is a meticulous process that demands a fusion of engineering expertise and advanced technology. It typically involves several stages: Design and Engineering: The process begins with conceptualizing the die’s design, taking into account factors like the desired product, material, tolerances, and production volume. Advanced computer-aided design (CAD) software assists in creating detailed digital blueprints. Material Selection: Choosing the appropriate material for the die is crucial for durability and precision. High-quality tool steels are often used due to their hardness, wear resistance, and thermal stability. Machining and Fabrication: Precision machinery, such as computer numerical control (CNC) mills and electrical discharge machining (EDM) equipment, is employed to shape and cut the die components according to the CAD design. This step demands utmost accuracy, as even minor deviations can impact the final product. Assembly: Various components of the die, such as punches, dies, and inserts, are meticulously assembled to create the final tool. The assembly process requires skilled technicians to ensure proper alignment and functionality. Testing and Refinement: The newly assembled die undergoes rigorous testing to ensure it meets the desired specifications. Adjustments and refinements are made as necessary to achieve optimal performance. Impact on Industries Metal stamping die manufacturers have a profound impact on various industries: Automotive Industry: Metal stamping dies are instrumental in producing car body panels, engine components, and intricate parts, contributing to the safety and aesthetics of vehicles. Electronics Sector: The production of electronic devices heavily relies on metal stamping dies for creating casings, connectors, and intricate internal components with precision and consistency. Consumer Appliances: Items like refrigerators, washing machines, and microwave ovens incorporate parts made using metal stamping dies, ensuring functionality and reliability. Aerospace and Aviation: Precision components used in aircraft and spacecraft, such as turbine blades and structural elements, are often manufactured using metal stamping dies. Medical Equipment: Metal stamping dies aid in the creation of medical devices and equipment, where precision and reliability are paramount. Innovation in Metal Stamping Die Manufacturing Advancements in technology continue to revolutionize the metal stamping die manufacturing landscape. Computer simulations and virtual prototyping help streamline the design process, reducing lead times and costs. Additionally, the integration of sensors and data analytics enhances the monitoring of die performance, enabling predictive maintenance and minimizing downtime. Conclusion Metal stamping die manufacturers are the architects of modern manufacturing, shaping the world around us through precision and innovation. Their expertise and dedication ensure that industries function smoothly, producing everything from everyday products to cutting-edge technologies. As technology advances, the world of metal stamping die manufacturing will undoubtedly continue to evolve, pushing the boundaries of what’s possible in the realm of precision metal shaping.