Metal Stamping Die: Precision in Forming Metal

Metal stamping die, often referred to simply as a “die,” is a crucial tool in the world of metalworking and manufacturing. It plays a pivotal role in transforming flat metal sheets into complex shapes, used in a wide range of industries, from automotive to electronics. In this article, we will delve into the fascinating world of metal stamping die, exploring its various types, applications, and the precision it offers in forming metal.

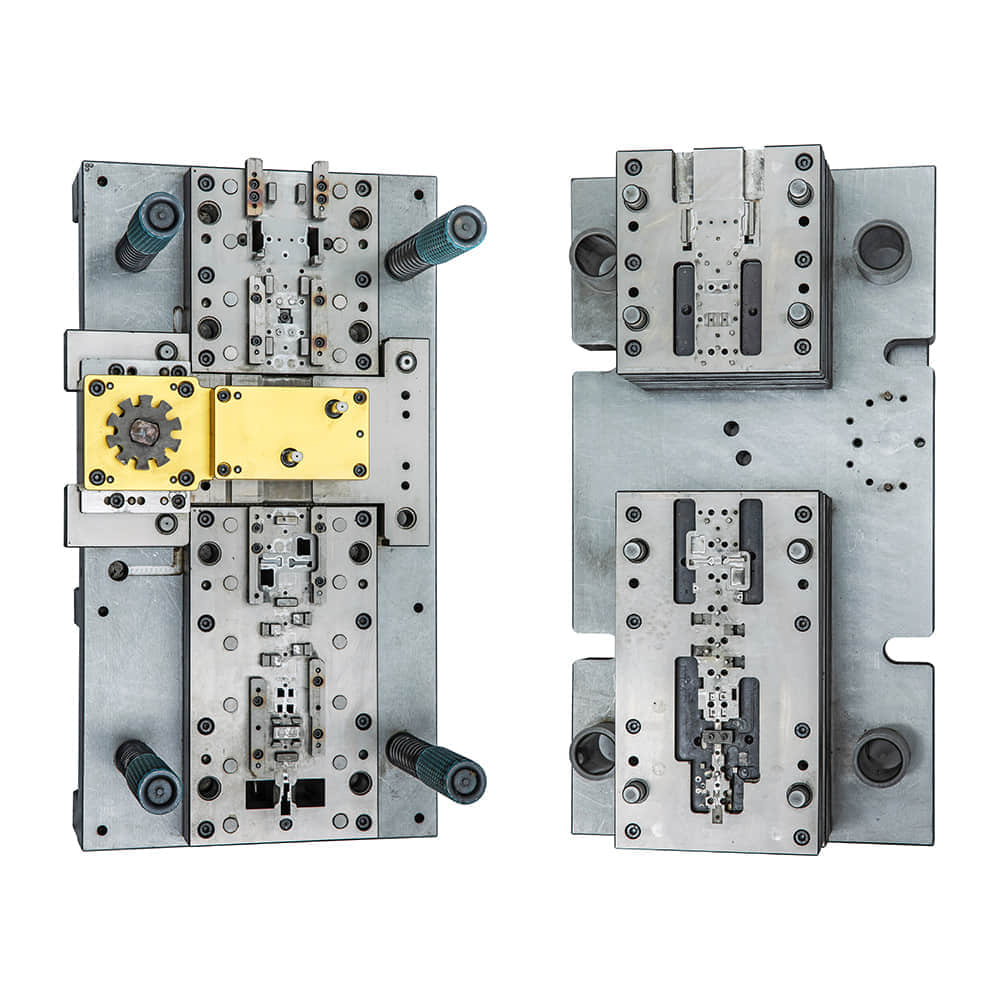

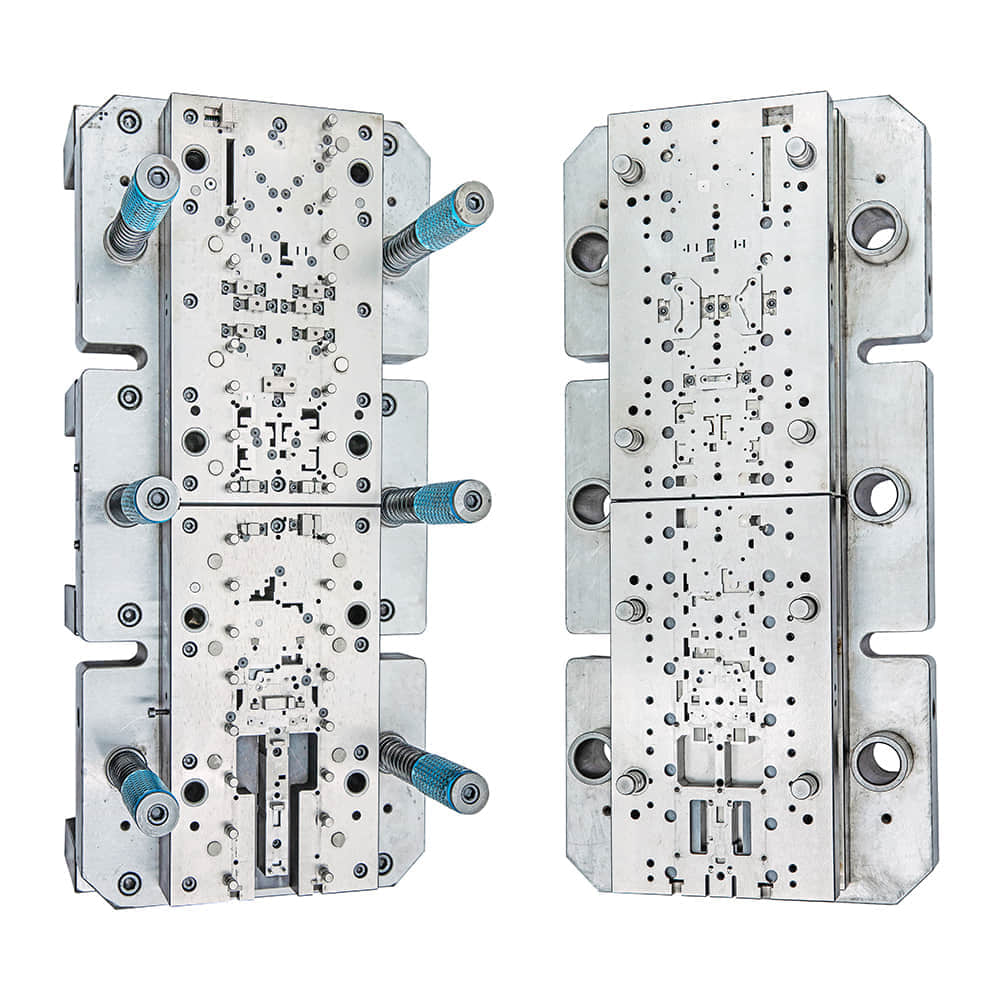

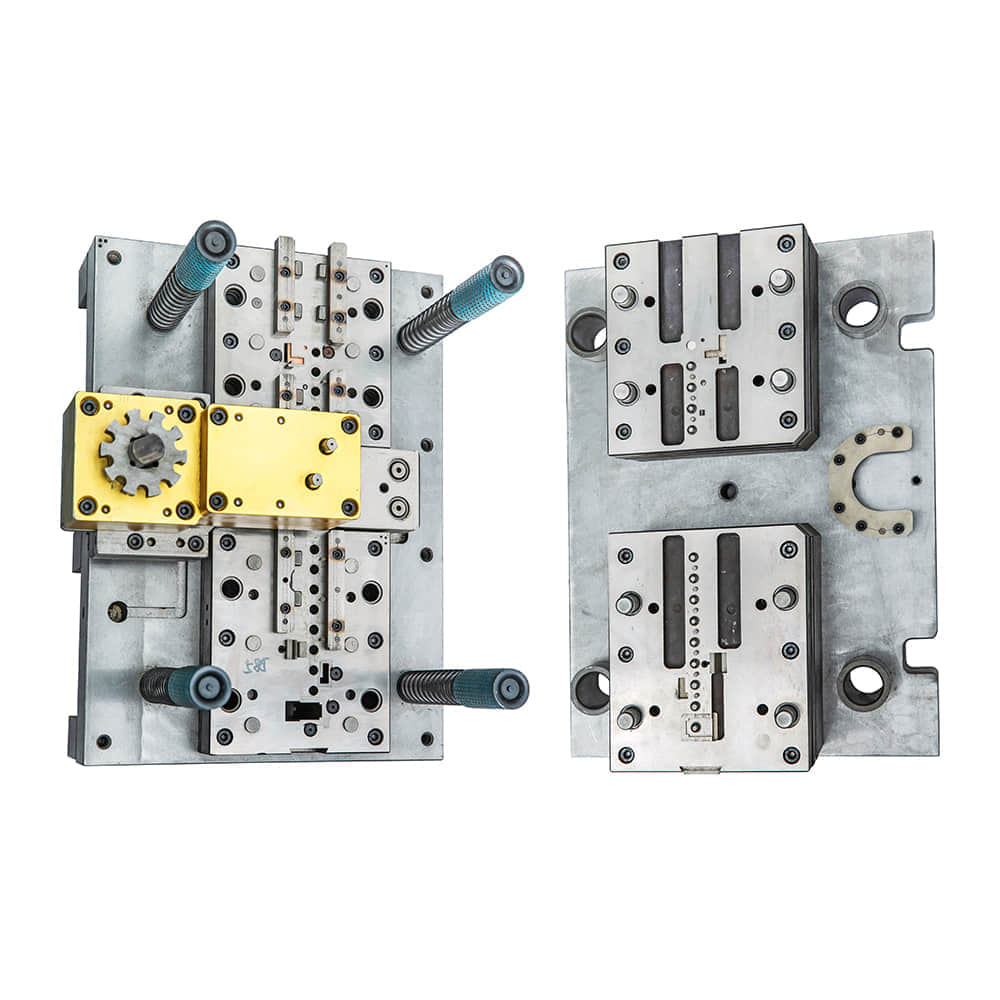

What is Metal Stamping Die? At its core, a metal stamping die is a specialized tool used to shape and cut metal sheets into desired forms. It consists of two main components: a male part (the punch) and a female part (the die). These parts work in tandem, with the punch pressing against the die to shape the metal sheet. The die contains cavities and contours that mirror the desired final shape, while the punch imparts force to transform the metal accordingly. Types of Metal Stamping Dies Blanking Dies: These dies are primarily used for cutting out flat pieces from a metal sheet. Common applications include producing washers, brackets, and electronic components. Piercing Dies: Piercing dies are employed to create holes or openings in metal sheets. This process is essential for manufacturing parts like gears, electrical connectors, and automobile chassis components. Forming Dies: Forming dies are used to bend and reshape metal sheets into specific shapes. They are commonly used in the production of car body panels, kitchen appliances, and consumer electronics casings. Progressive Dies: These are complex dies that perform multiple operations in a single pass, including cutting, bending, and shaping. Progressive dies are highly efficient and find extensive use in mass production, such as in the automotive industry. Drawing Dies: Drawing dies are essential for creating deep, cup-like shapes, such as pots and pans or cylindrical components like cans and containers. Applications of Metal Stamping Dies The applications of metal stamping dies are vast and diverse. Here are a few industries that heavily rely on this technology: Automotive Industry: Metal stamping dies are extensively used in manufacturing car body parts, engine components, and various interior and exterior accessories. Electronics: In the electronics industry, metal stamping dies help create the intricate components needed for devices like smartphones, tablets, and laptops. Aerospace: Aerospace manufacturers use metal stamping dies to produce components for aircraft and spacecraft, including structural elements and engine parts. Appliances: The household appliance industry relies on metal stamping to create components for refrigerators, ovens, and washing machines. Construction: Metal stamping dies are crucial for fabricating structural components used in construction, such as brackets, beams, and panels. The Precision Advantage One of the standout features of metal stamping dies is their ability to deliver exceptional precision and consistency in part production. These dies are engineered to incredibly tight tolerances, ensuring that each stamped part is identical to the next. This precision is essential in industries like aerospace and automotive, where safety and performance standards are non-negotiable. Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has further enhanced the precision of metal stamping dies. CAD allows engineers to design intricate and complex die shapes with incredible accuracy, while CAM ensures that these designs are translated into the physical die components with the utmost precision. Conclusion In the world of metalworking and manufacturing, metal stamping dies are unsung heroes. They enable the creation of intricate metal components that form the backbone of countless industries. From automotive to electronics, these dies have a profound impact on the products we use every day. Their precision and versatility continue to drive innovation and shape the future of manufacturing. As technology advances, we can expect metal stamping dies to play an even more vital role in the creation of the products that define our modern world.