In the realm of modern manufacturing, injection molding stands tall as a versatile and efficient method for producing a wide array of plastic parts. Injection molded parts manufacturers play a pivotal role in this process, contributing to various industries ranging from automotive and electronics to medical devices and consumer goods. In this article, we delve into the world of injection molded parts manufacturers, exploring their significance, processes, and impact on today’s manufacturing landscape.

The Significance of Injection Molded Parts Manufacturers

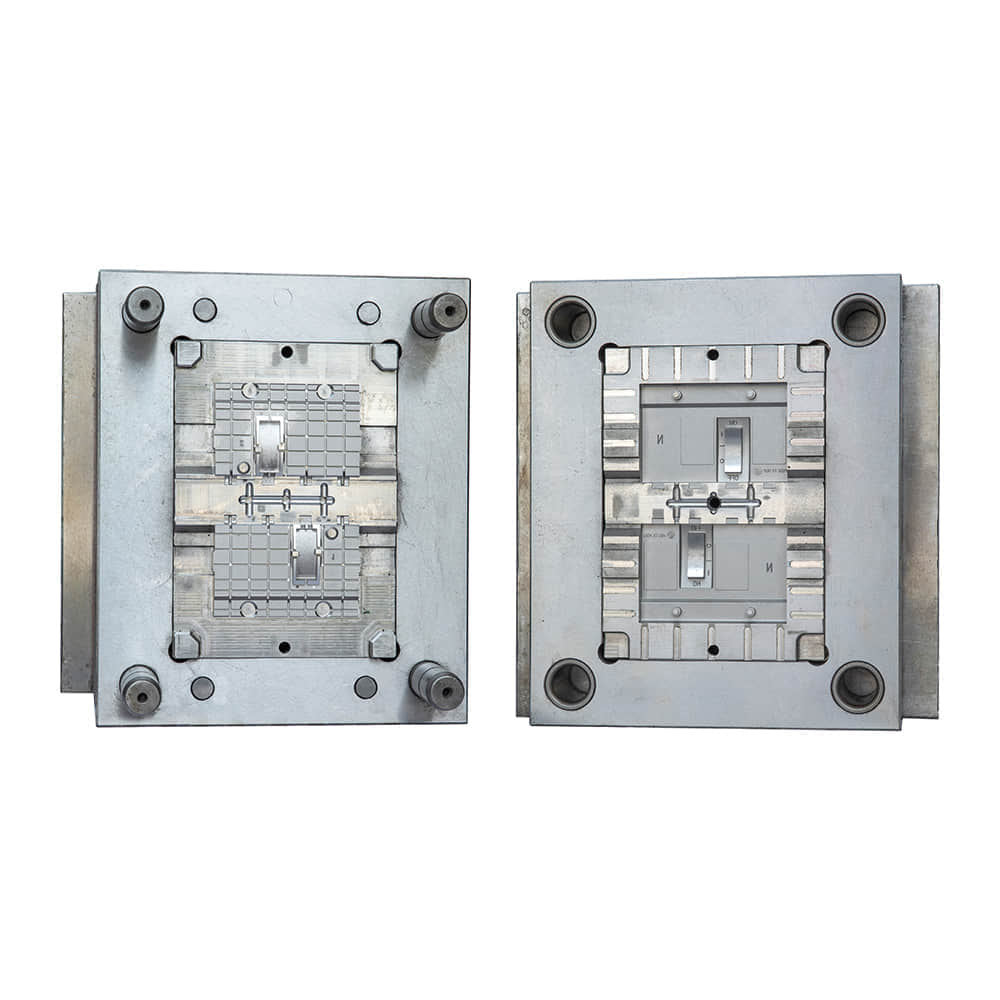

Injection molded parts are ubiquitous in our daily lives, found in items as diverse as packaging, electronic casings, and interior automotive components. The role of injection molded parts manufacturers is to transform raw plastic materials into these essential components using specialized machinery and techniques. These manufacturers provide a cost-effective solution for mass production. The process allows for high-volume production with consistent quality, making it an ideal choice for products that require precision and uniformity. This method also facilitates the creation of intricate designs and complex geometries that might be otherwise difficult to achieve with traditional manufacturing techniques. The Injection Molding Process At the heart of injection molding lies a carefully orchestrated process. It begins with the selection of raw plastic materials, which are melted and injected into a mold cavity under high pressure. The mold, typically made of steel or aluminum, is designed to shape the plastic into the desired form. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. This cycle can be repeated numerous times, allowing for the rapid production of a large number of parts. Injection molded parts manufacturers employ skilled engineers, designers, and technicians who collaborate to create precise molds and ensure the quality of the final products. Modern technology has further enhanced the process, with computer simulations and advanced machinery aiding in optimizing mold design and material usage. Impacting Diverse Industries The influence of injection molded parts manufacturers extends across industries, making them a linchpin of modern manufacturing. In the automotive sector, these manufacturers contribute to producing components such as bumpers, dashboards, and interior trims. In electronics, they craft casings for smartphones, laptops, and various consumer gadgets. The medical field benefits from injection molded parts in the form of syringes, IV connectors, and diagnostic equipment casings. Manufacturers also cater to the packaging industry by producing bottles, caps, and containers of all shapes and sizes. Advancements and Sustainability As sustainability becomes a paramount concern, injection molded parts manufacturers are adapting their practices. Many are incorporating recycled plastics and exploring biodegradable materials to reduce environmental impact. Furthermore, advancements in automation and robotics are streamlining production processes, enhancing efficiency, and minimizing waste. The Future of Injection Molded Parts Manufacturers Looking ahead, injection molded parts manufacturers are poised to continue their pivotal role in the manufacturing landscape. With ongoing advancements in materials, processes, and automation, the potential for innovation remains vast. Customization and personalization are likely to become more prevalent, allowing manufacturers to cater to specific client needs with unparalleled precision. In conclusion, injection molded parts manufacturers are the unsung heroes driving modern manufacturing across a multitude of industries. Their expertise in transforming raw plastic materials into intricate, functional components showcases the remarkable capabilities of today’s manufacturing technology. As innovation propels us into the future, these manufacturers will undoubtedly remain at the forefront of shaping how we create, assemble, and interact with everyday products.