In today’s dynamic manufacturing landscape, injection molding stands as a vital process that shapes countless products we use daily. Central to this process are injection mold manufacturers, the unsung heroes responsible for crafting the intricate molds that form the backbone of the manufacturing industry.

The Essence of Injection Mold Manufacturers

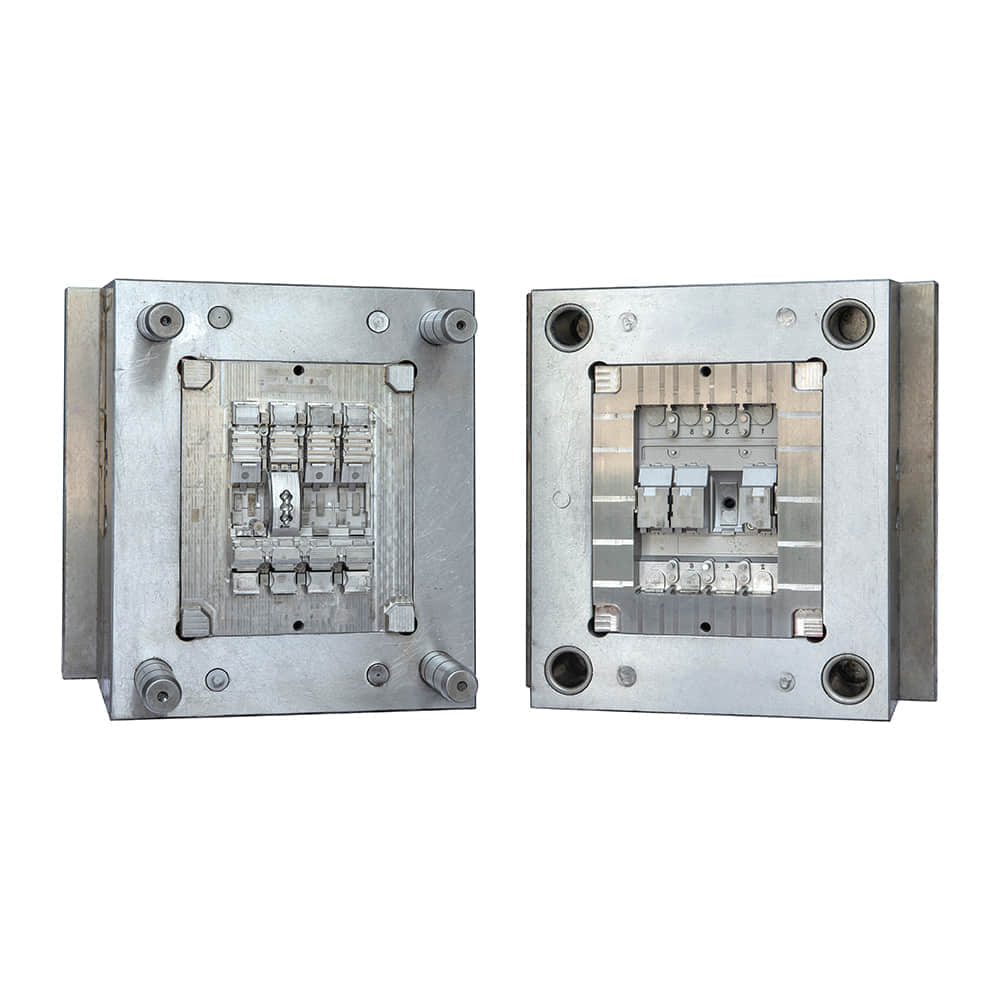

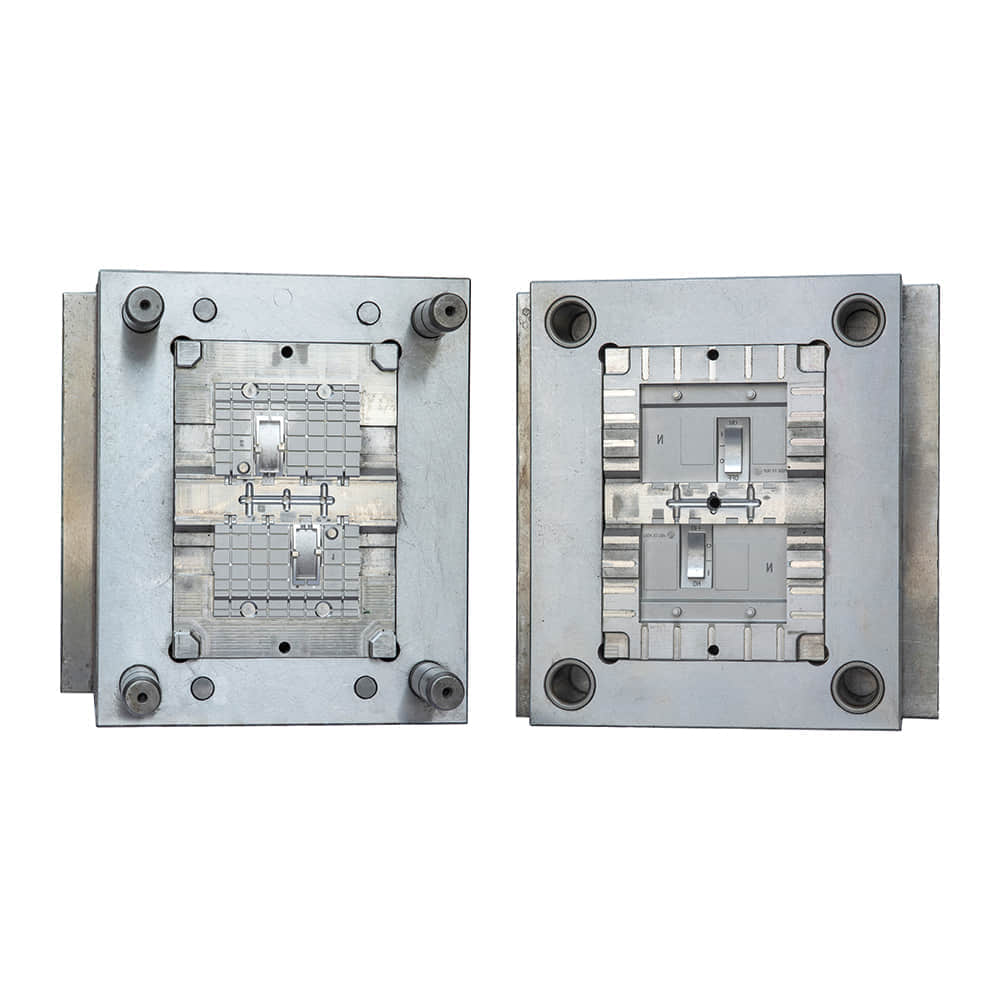

Injection mold manufacturers play a pivotal role in bringing designs to life. Their expertise lies in creating molds that enable the production of a wide array of items, from intricate medical devices to everyday consumer goods. These molds serve as the blueprint for the final product, dictating its dimensions, textures, and even its functionality. Meticulously designed molds result in products that meet the highest standards of quality and precision. Precision and Innovation The heart of injection molding lies in precision, and injection mold manufacturers are at the forefront of delivering it. They harness cutting-edge technologies to design molds with incredible accuracy. Computer-Aided Design (CAD) software allows them to translate intricate designs into detailed specifications, ensuring that each mold component fits together seamlessly. This commitment to precision minimizes defects, reduces waste, and streamlines the manufacturing process. Moreover, innovation is a driving force in this field. Injection mold manufacturers constantly seek novel ways to improve mold design and construction. Advanced materials, such as high-performance alloys and composite polymers, are integrated to enhance durability and longevity. Manufacturers also explore intricate cooling and ejection mechanisms, resulting in faster production cycles and increased efficiency. Collaboration and Customization Collaboration is another key aspect of the injection mold manufacturing process. Manufacturers work closely with product designers and engineers to understand the intended functionality and aesthetics of the final product. This collaboration ensures that the mold aligns with the product’s specifications and manufacturing requirements. Customization is often the norm, as each project demands unique molds tailored to its distinct needs. Quality Assurance and Compliance Injection mold manufacturers uphold stringent quality assurance standards. Molds undergo rigorous testing to ensure they can withstand the demands of high-volume production. Manufacturers also adhere to industry regulations and guidelines, ensuring the molds meet safety and environmental standards. Global Impact The influence of injection mold manufacturers extends globally. They cater to industries spanning automotive, electronics, medical, consumer goods, and more. Regardless of the sector, the precision molds they produce significantly contribute to the products we rely on daily. The global nature of modern manufacturing means that injection mold manufacturers can collaborate with clients and partners from around the world, exchanging knowledge and expertise to drive innovation further. Sustainability and Future Trends As sustainability takes center stage, injection mold manufacturers are actively seeking eco-friendly solutions. They explore biodegradable materials, energy-efficient processes, and recyclable mold components to reduce the environmental impact of production. This commitment to sustainability reflects the industry’s dedication to responsible manufacturing practices. Looking ahead, the future of injection mold manufacturing holds exciting prospects. Additive manufacturing, or 3D printing, is poised to revolutionize the field, enabling the creation of complex molds with unprecedented ease. The integration of artificial intelligence and machine learning may enhance mold design and production efficiency, further elevating the industry’s capabilities. Conclusion Injection mold manufacturers are the unsung heroes of modern manufacturing, contributing significantly to the products that shape our lives. Their expertise, precision, and dedication to innovation ensure that our world is filled with high-quality items, ranging from essential medical devices to innovative consumer gadgets. As technology continues to advance, these manufacturers will remain at the forefront of shaping the future of manufacturing, one mold at a time.