Introduction

In the realm of manufacturing and metalworking, various tools and techniques contribute to the creation of intricate and precise products. One such essential tool is the blanking die. This article delves into the world of blanking dies, shedding light on their significance, functionality, and the role they play in shaping modern production processes.

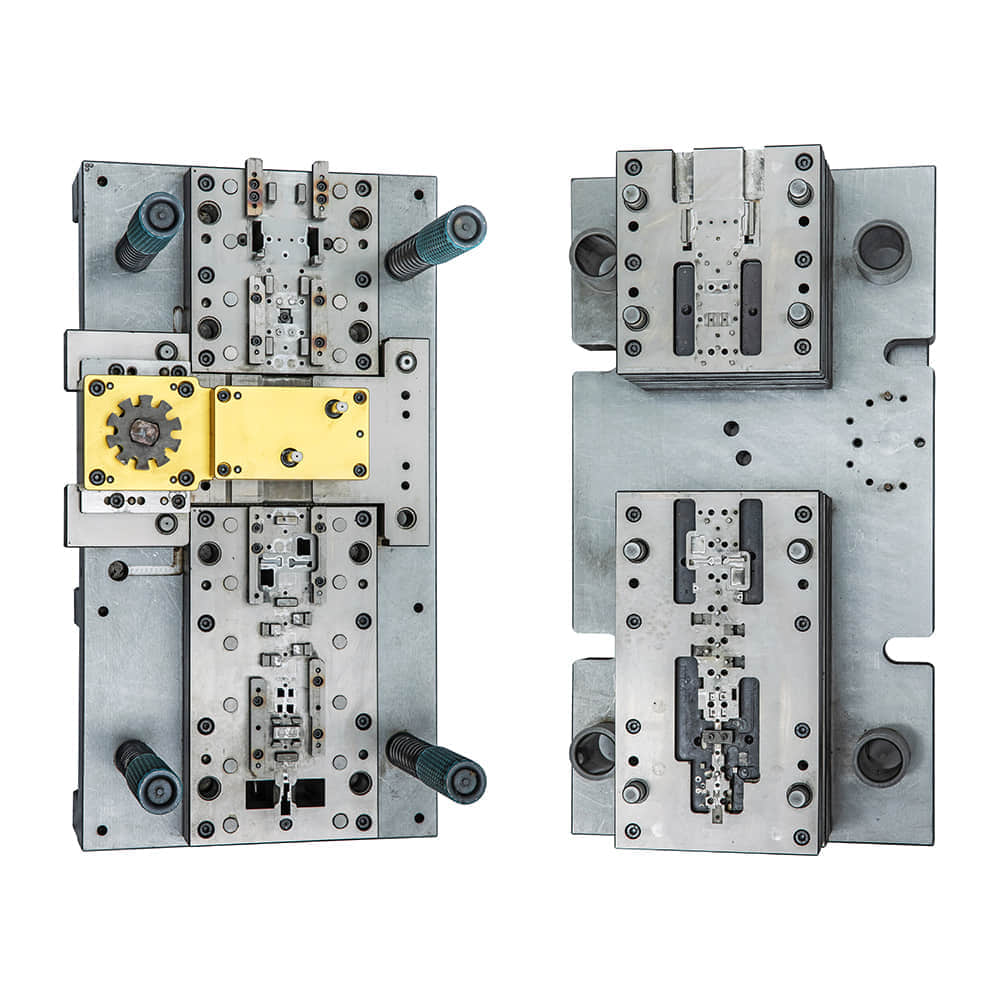

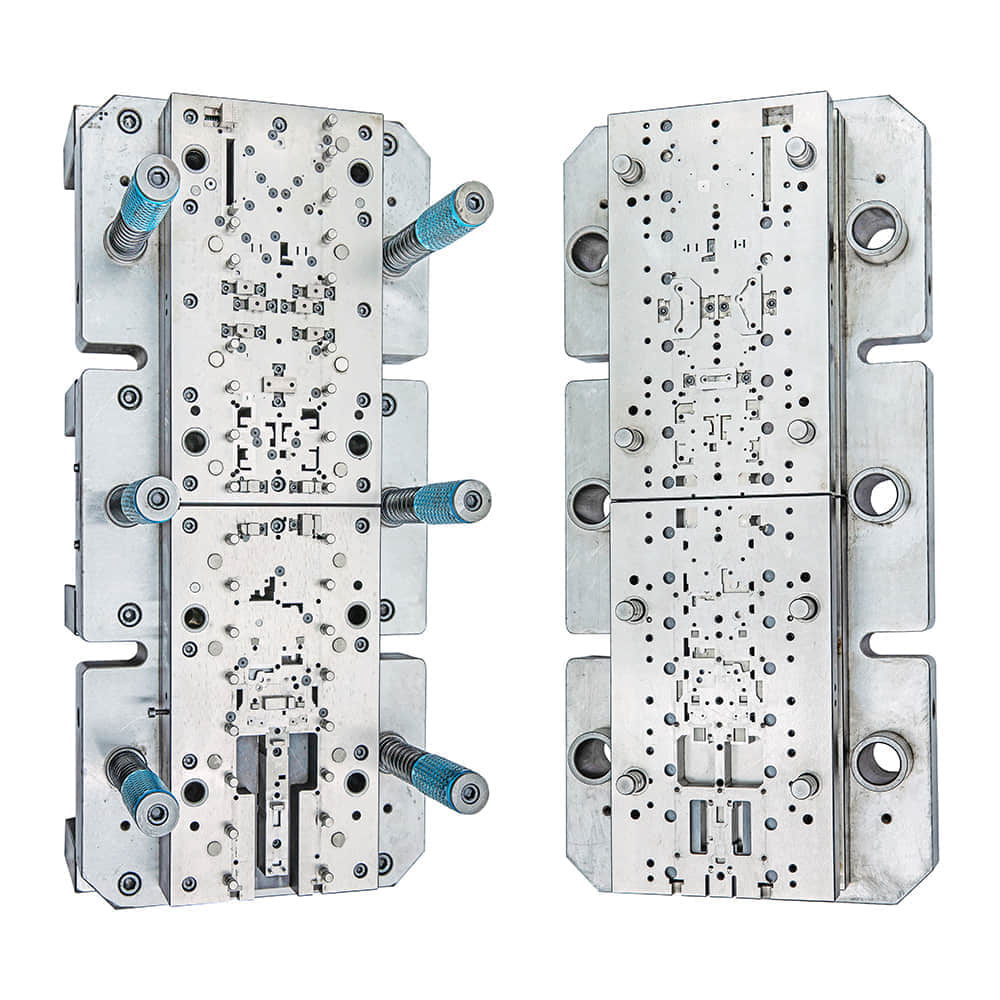

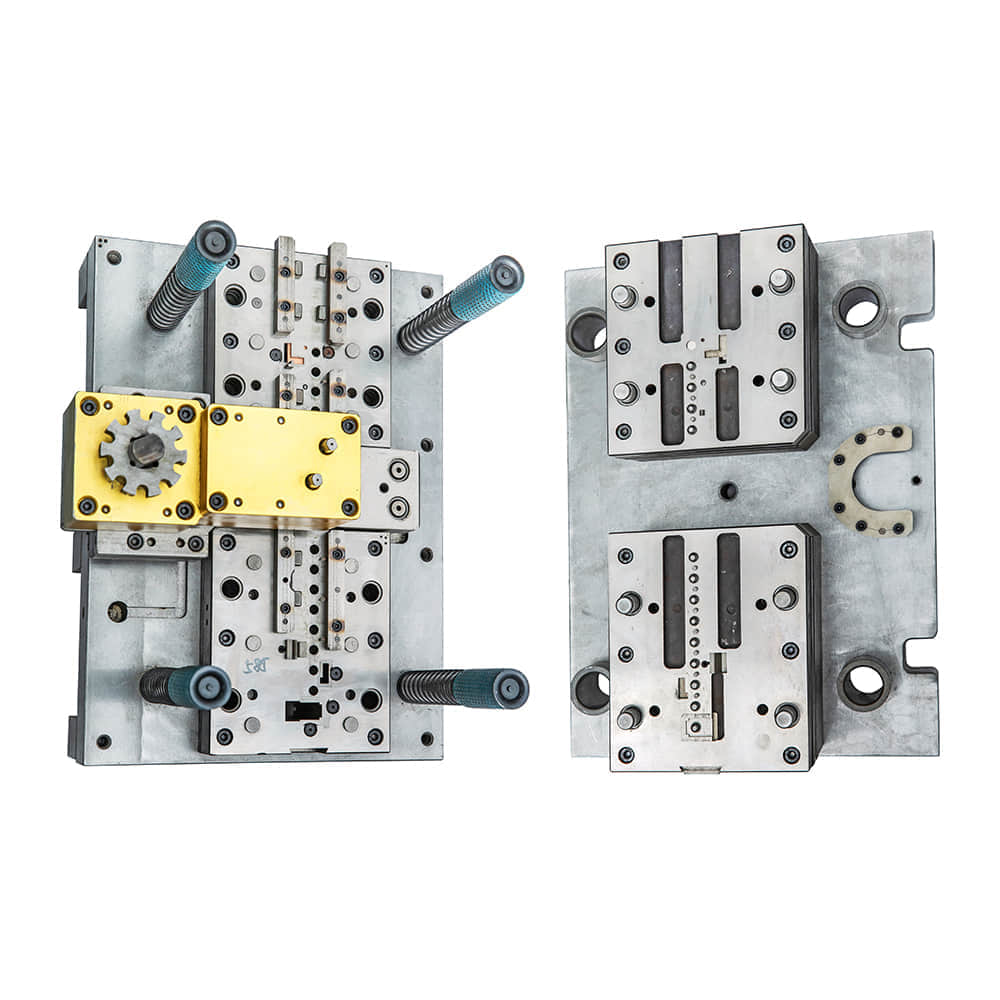

Understanding Blanking Dies Blanking dies are specialized tools used in the manufacturing industry to cut and shape flat pieces of sheet metal or other materials into desired shapes with precision and accuracy. They are an integral part of the blanking process, where a sheet of material is subjected to a die that cleanly cuts out the desired shape, leaving behind the waste material known as the “blank.” These blanks can further undergo various operations like bending, forming, or stamping to create final products such as automotive parts, electronic components, and household appliances. The Functionality of Blanking Dies The primary function of blanking dies is to produce consistent and accurate shapes from sheet materials. This is achieved through the interaction between the blanking die and a press machine. The die consists of two main parts: the punch and the die block. The punch is the component that pushes down on the sheet material, while the die block is the stationary part that contains the desired shape cutout. When the punch and die block come together, the sheet material is sheared along the edges of the cutout, resulting in the creation of the desired blank. The design and precision of blanking dies are crucial to achieving high-quality end products. Engineers and toolmakers carefully consider factors such as material thickness, material properties, cutting clearances, and the overall geometry of the die to ensure that the blanks are produced with minimal burrs, uniform dimensions, and smooth edges. These factors not only impact the aesthetics of the final product but also influence its functionality and performance. Applications Across Industries The versatility of blanking dies makes them indispensable across various industries. In the automotive sector, blanking dies are used to create components such as body panels, brackets, and engine parts. The electronics industry relies on them for producing intricate parts used in devices like smartphones, tablets, and computers. Additionally, household appliances, aerospace components, and packaging materials owe their precise shapes to the application of blanking dies. Advancements in Blanking Die Technology As technology continues to advance, so does the field of manufacturing. Blanking die technology has also witnessed significant improvements. Computer-aided design (CAD) software enables engineers to create highly intricate and customized die designs. Moreover, computer numerical control (CNC) machining has enhanced the precision of die production, resulting in faster turnaround times and reduced material waste. These advancements contribute to the overall efficiency of the blanking process and elevate the quality of end products. Conclusion In the intricate dance of modern manufacturing, blanking dies take center stage as crucial tools for shaping raw materials into precise and functional components. Their role in creating a wide array of products across industries underscores their significance. As technology propels manufacturing processes forward, the evolution of blanking die technology stands as a testament to human ingenuity and the relentless pursuit of excellence in production.