In the world of modern manufacturing, precision and efficiency are paramount. Among the myriad processes that contribute to the production of complex metal components, metal stamping stands out as a cornerstone technique. At the heart of this process lies the Metal Stamping Die OEM Manufacturer, an unsung hero playing a pivotal role in shaping industries across the globe.

The Essence of Metal Stamping Die OEM Manufacturers

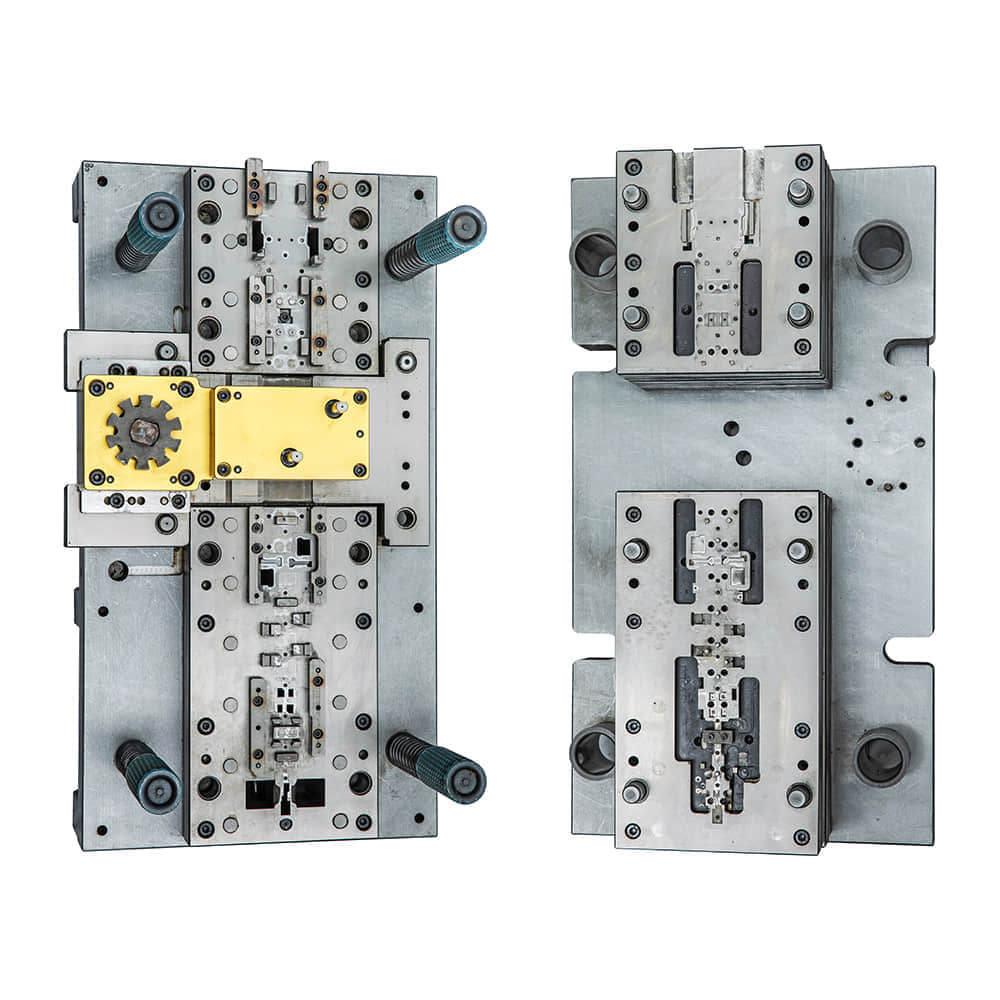

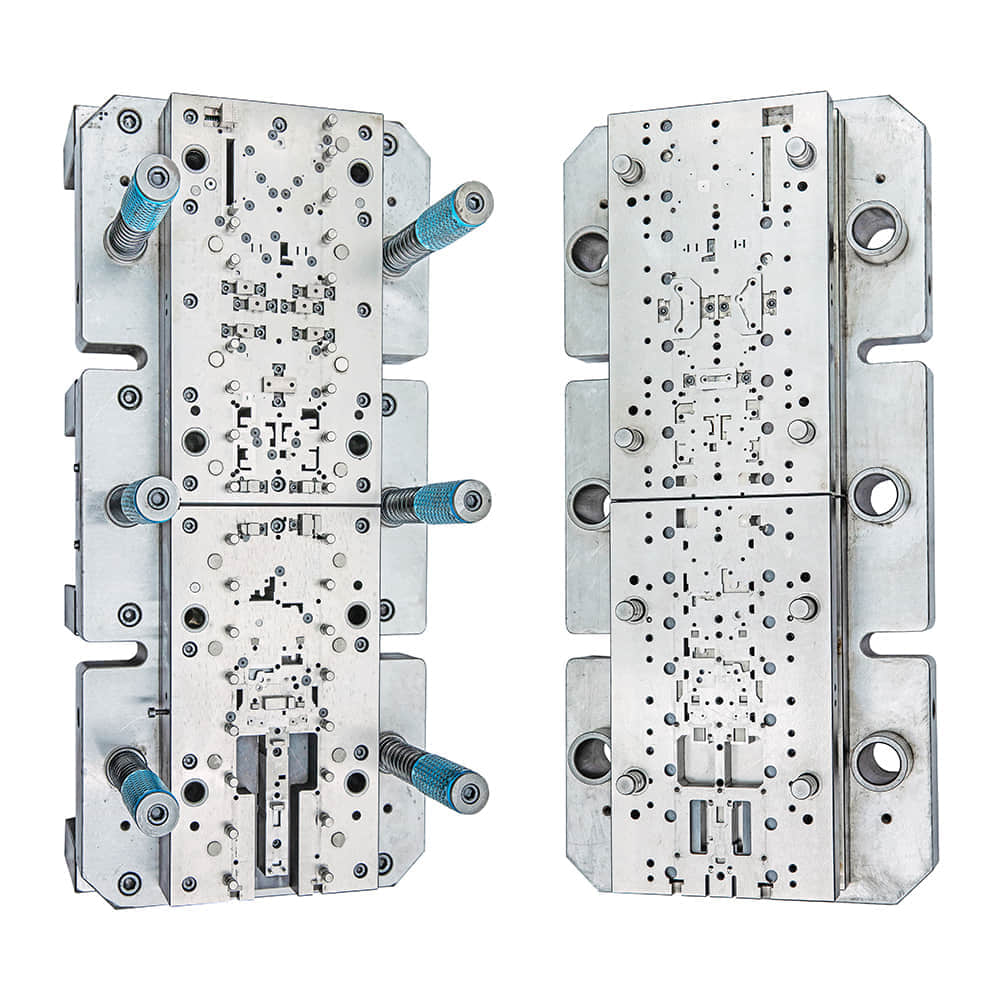

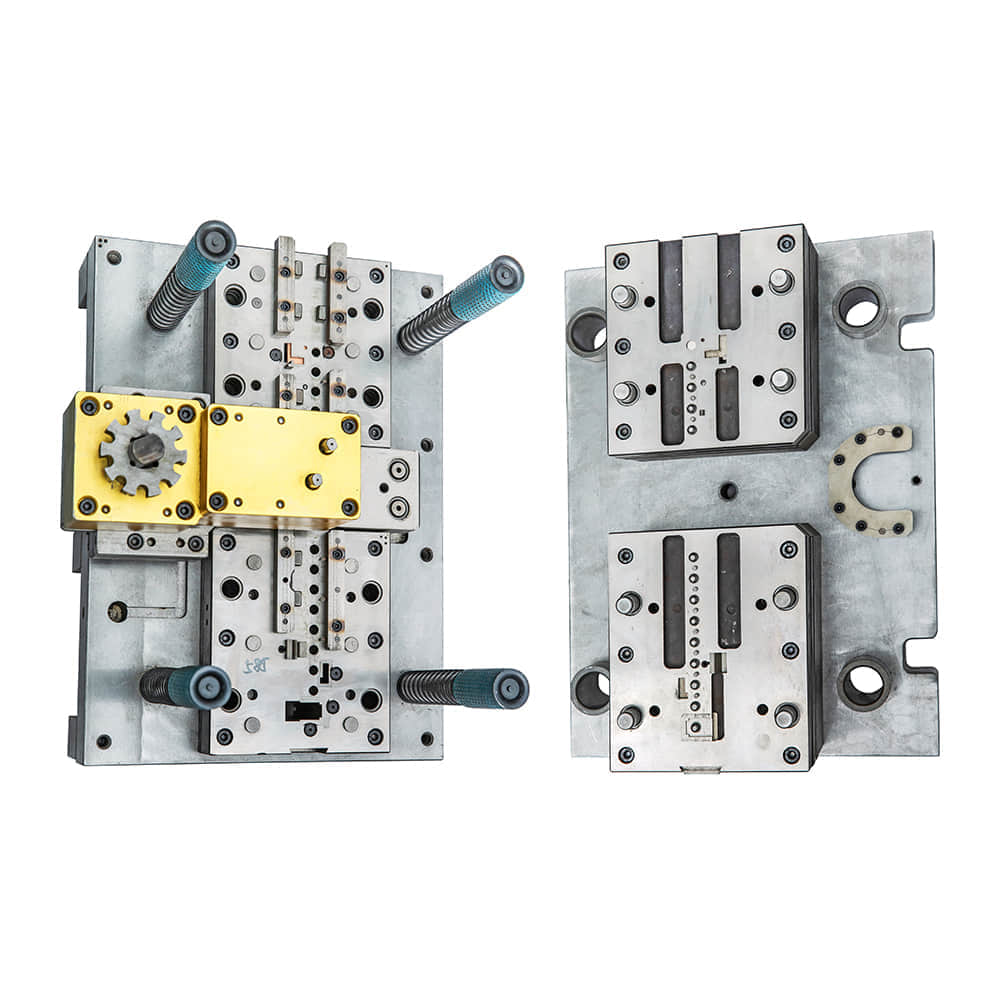

Metal stamping is a manufacturing process that transforms flat metal sheets into intricate shapes through pressing, forming, and cutting. The pivotal element of this process is the metal stamping die – a specialized tool that defines the final product’s design with remarkable accuracy and consistency. Original Equipment Manufacturers (OEMs) in this field are the masterminds behind these dies, often working behind the scenes to enable the production of countless everyday items. Precision Engineering at Its Core Metal stamping die OEM manufacturers are synonymous with precision engineering. They meticulously design and fabricate dies with tight tolerances, ensuring that each stamped part adheres to the desired specifications. These manufacturers employ advanced techniques like computer-aided design (CAD) and computer-aided manufacturing (CAM) to create dies that guarantee uniformity in production and minimal waste of resources. Customization – Meeting Diverse Industry Needs The versatility of metal stamping die OEM manufacturers is evident in their ability to cater to a wide range of industries. From automotive to electronics, aerospace to medical equipment, these manufacturers produce dies tailored to specific needs. This level of customization ensures that manufacturers in different sectors can rely on these experts to produce components that align perfectly with their requirements. Innovation in Material Usage Advancements in material science have significantly impacted the metal stamping die manufacturing sector. Modern OEM manufacturers are not only skilled in working with traditional metals like steel and aluminum but also adept at handling exotic and composite materials. This capability expands the possibilities for industries, allowing them to explore new avenues in lightweighting, durability, and performance. Efficiency and Cost-Effectiveness Metal stamping die OEM manufacturers contribute to the efficiency of the manufacturing ecosystem. Their expertise minimizes production errors, reduces lead times, and maximizes material utilization. This, in turn, enhances cost-effectiveness for both the OEM manufacturer and their clients. By optimizing the manufacturing process, metal stamping die OEM manufacturers play a crucial role in keeping production lines running smoothly. The Symbiotic Partnership The relationship between metal stamping die OEM manufacturers and the industries they serve is symbiotic. While these manufacturers remain largely in the background, their influence reverberates through supply chains. They work hand in hand with manufacturers to develop dies that align with their vision, ensuring that the end products maintain consistency and quality. Looking Ahead As technology continues to evolve, metal stamping die OEM manufacturers find themselves at the crossroads of innovation. Additive manufacturing, simulation technologies, and further advancements in materials are reshaping the landscape. These manufacturers are not only adapting to change but actively driving it, pushing the boundaries of what’s possible in the realm of precision metal component production. In conclusion, Metal Stamping Die OEM Manufacturers are the unsung champions of modern manufacturing. Their mastery over precision engineering, versatility across industries, and commitment to innovation propel industries forward. As we move into an era of ever more intricate and demanding designs, these manufacturers are poised to lead the charge, ensuring that the world of metal stamping continues to thrive.