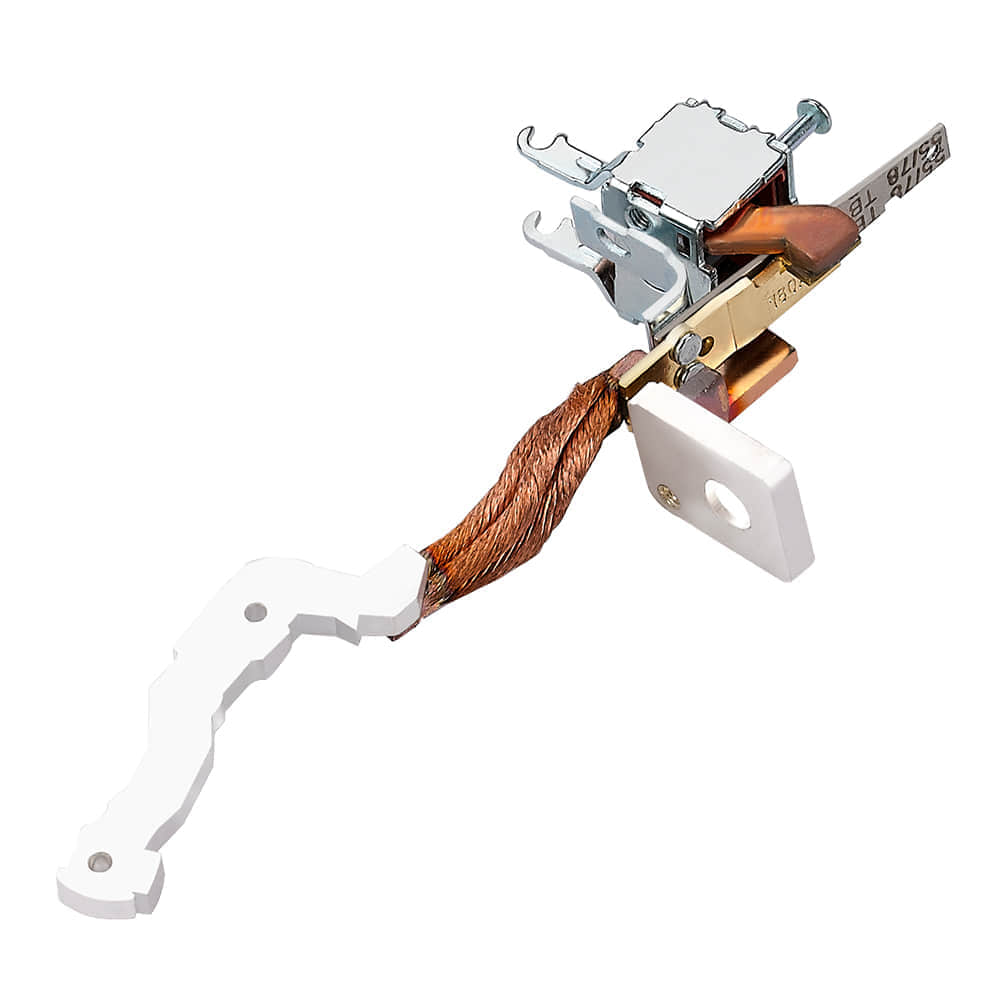

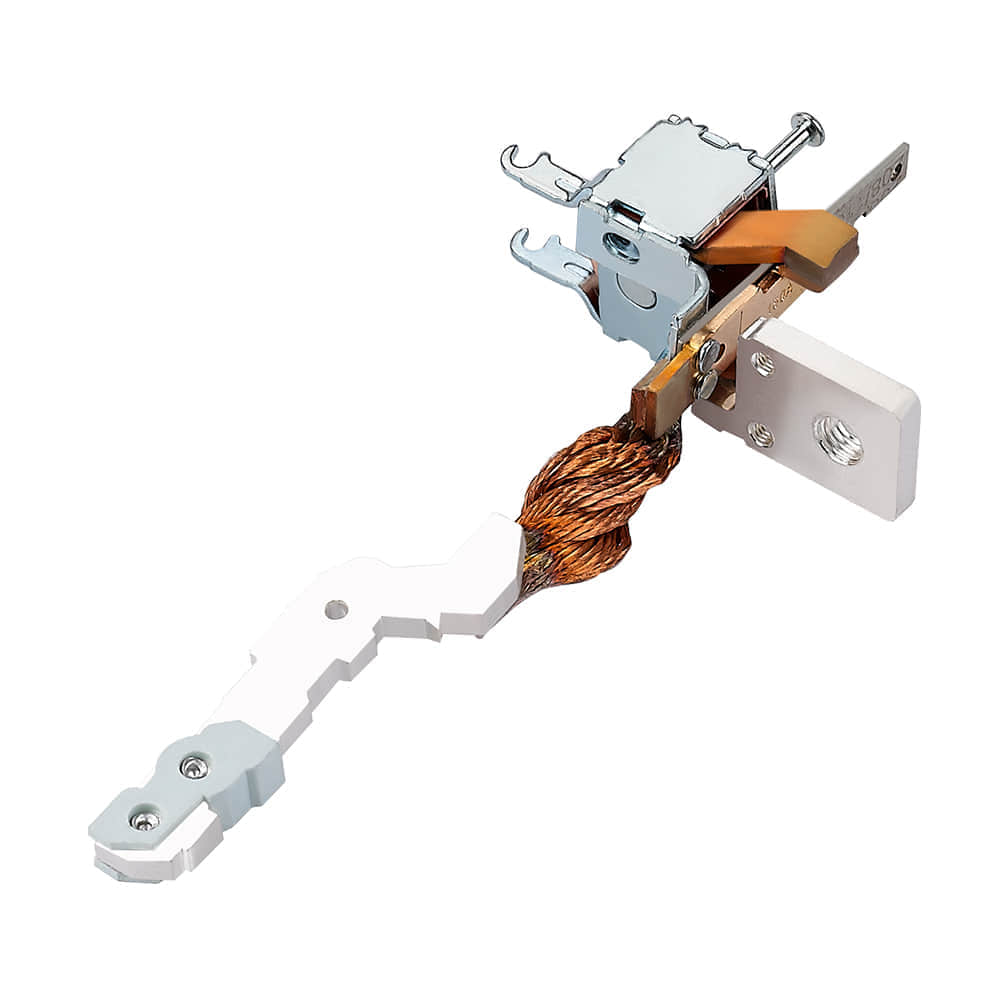

Metal Stamping Parts: Precision in Manufacturing

In the realm of modern manufacturing, metal stamping has emerged as a vital technique that combines precision, efficiency, and versatility. Metal stamping involves transforming flat metal sheets into various intricate shapes through pressing, bending, punching, and more. This process plays a pivotal role in creating components for industries ranging from automotive and aerospace to electronics and beyond. In this article, we delve into the world of metal stamping parts, exploring their significance, manufacturing process, and wide-ranging applications.

The Significance of Metal Stamping Parts Metal stamping is a highly efficient and cost-effective method for producing parts with consistent quality and accuracy. It allows manufacturers to rapidly produce large quantities of components while maintaining tight tolerances. This process offers versatility in terms of material selection, making it possible to work with a diverse range of metals including steel, aluminum, copper, and alloys. The Manufacturing Process The process of metal stamping involves several key stages: Design and Prototyping: Engineers create detailed designs and prototypes of the desired part. Computer-aided design (CAD) software plays a crucial role in this phase, enabling precise modeling and simulations. Tool and Die Creation: Tool and die makers then craft the specialized tools required for the stamping process. These tools, often made of hardened steel, are designed to accurately shape and cut the metal sheets. Material Selection: Manufacturers select the appropriate metal sheet for the specific application, considering factors such as strength, corrosion resistance, and cost. Stamping Process: The metal sheet is fed into the stamping press, where it is subjected to various forces that shape it according to the design. This may involve bending, blanking, embossing, coining, or deep drawing. Quality Control: Rigorous inspections are conducted throughout the process to ensure dimensional accuracy, surface finish, and overall quality of the stamped parts. Applications Across Industries Metal stamping parts find their applications across diverse industries: Automotive: From chassis components to intricate engine parts, metal stamping is a cornerstone of automotive manufacturing, contributing to vehicle safety and performance. Electronics: Precision parts used in electronic devices, including connectors, brackets, and heat sinks, are often manufactured through stamping. Aerospace: The aerospace sector relies on metal stamping for crafting lightweight yet robust components that meet strict industry standards. Medical Devices: Stamping is used to produce medical instruments and equipment, ensuring precision and reliability in healthcare applications. Consumer Goods: Items such as kitchen appliances, hardware, and even decorative pieces are manufactured using metal stamping processes. Advantages and Future Trends Metal stamping offers numerous advantages, including high production speeds, repeatable accuracy, and the ability to maintain tight tolerances. Furthermore, advancements in technology, such as computerized numerical control (CNC) systems and innovative die designs, continue to enhance the efficiency and capabilities of metal stamping. Looking ahead, the industry is witnessing a trend toward increased automation and the integration of artificial intelligence for process optimization. This not only boosts production rates but also enhances the adaptability of metal stamping for complex and customized components. In Conclusion Metal stamping parts stand as a testament to human engineering prowess, combining design, material science, and precision manufacturing. With its wide-ranging applications and ever-evolving techniques, metal stamping remains a critical process in modern industrial production. As industries continue to demand high-quality components produced at scale, the significance of metal stamping parts is poised to grow, shaping the technological landscape for years to come.