Metal Stamping Die: Merging Precision and Craftsmanship for Manufacturing Excellence

In the world of metalworking, precision and efficiency are paramount. Among the many techniques that cater to these requirements, metal stamping stands out as a highly effective method for mass-producing intricate metal components. At the heart of this process lies the unsung hero, the metal stamping die. This article delves into the fascinating realm of metal stamping dies, where artistry and engineering unite to shape the modern manufacturing landscape.

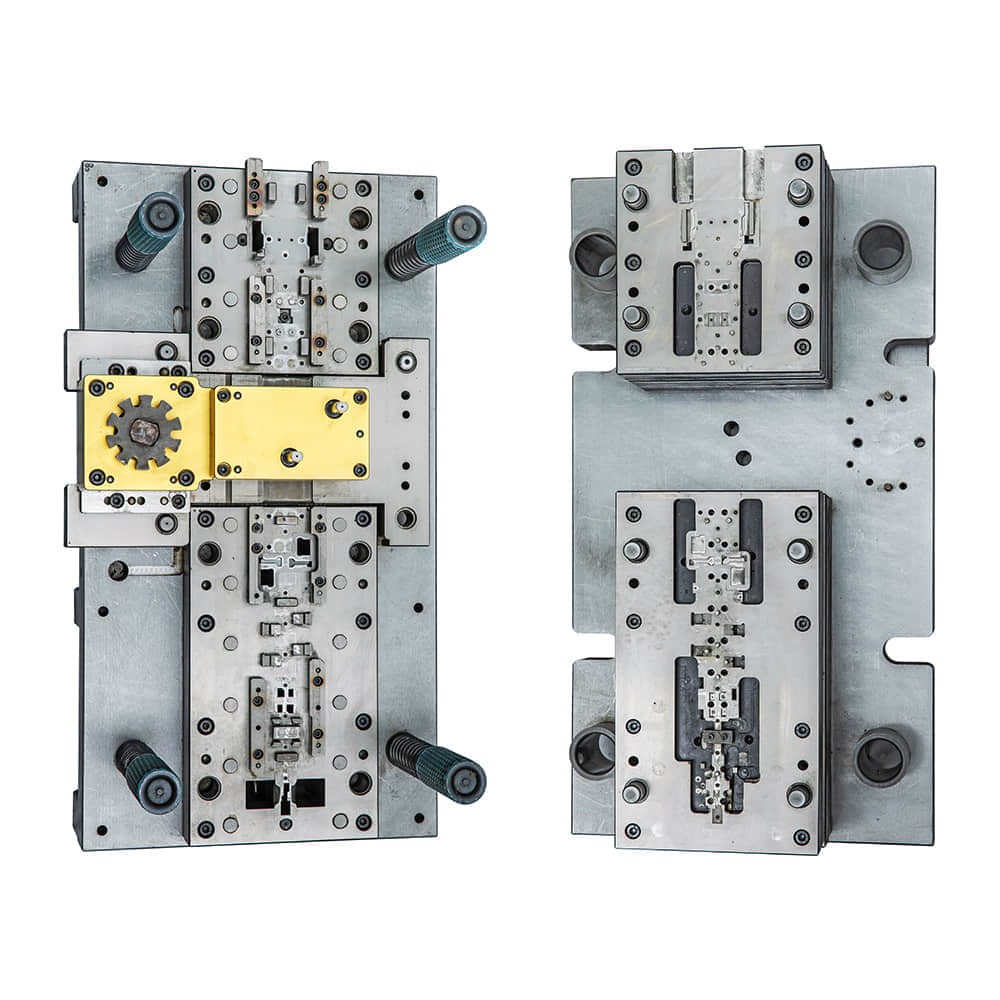

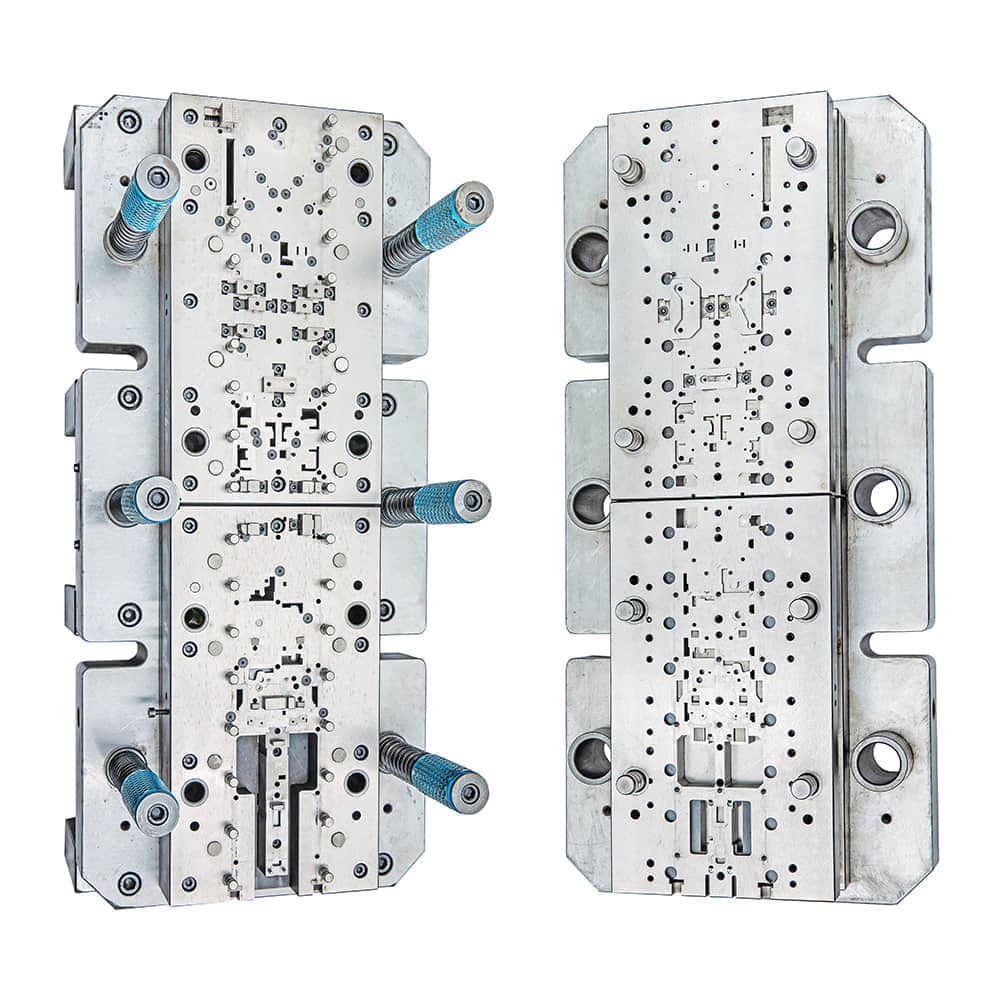

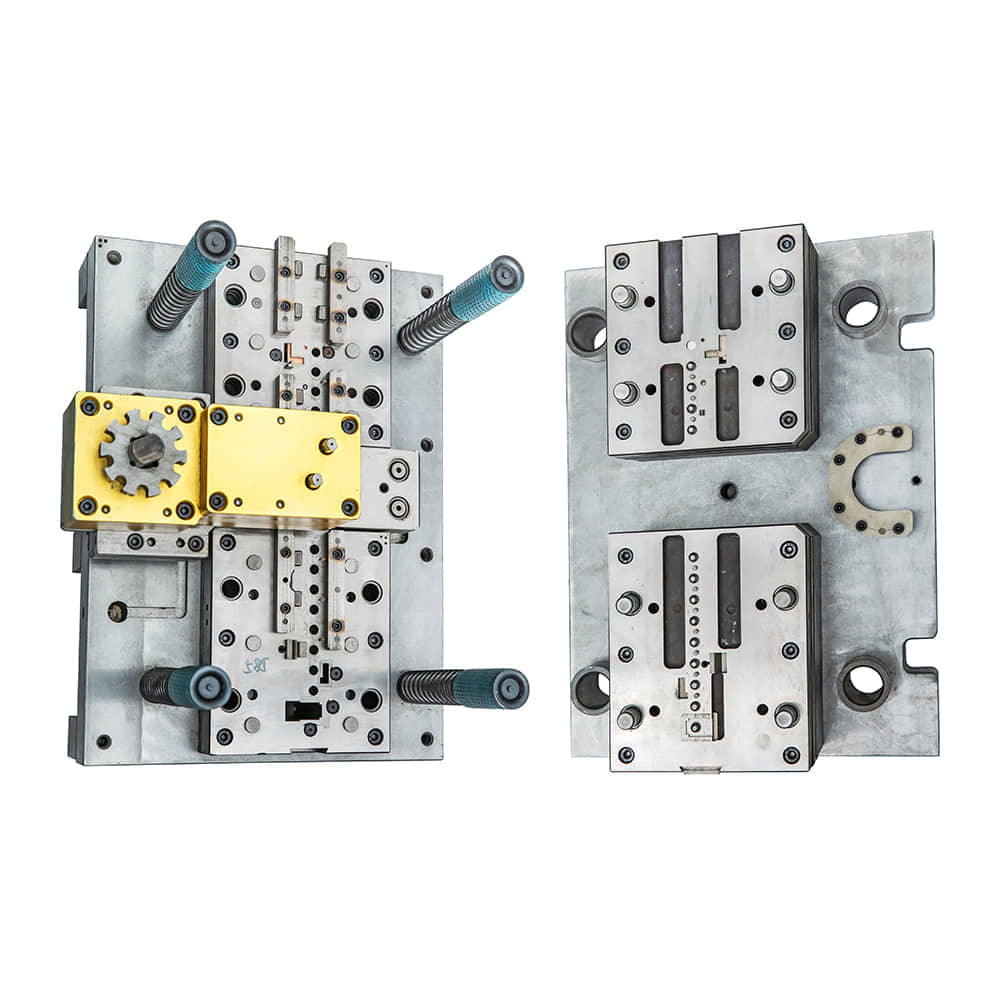

The Essence of Metal Stamping Dies Metal stamping dies are specialized tools used in the metal stamping process to shape, cut, or transform flat metal sheets into the desired form. These dies, often made from high-strength tool steels, are meticulously crafted to withstand the immense pressures and forces involved in the stamping process. They come in various types, including blanking dies, piercing dies, bending dies, and forming dies, each tailored to a specific task in the production line. Precision Engineering: The Backbone of Metal Stamping Dies Crafting a metal stamping die is a symphony of precision engineering and skilled craftsmanship. Computer-Aided Design (CAD) software plays a pivotal role, allowing engineers to create intricate designs with micron-level accuracy. Every contour, every curve is meticulously planned to ensure the final product conforms to the desired specifications. Once the design is established, Computer-Aided Manufacturing (CAM) software takes over, generating the tool paths that guide the cutting and shaping mechanisms. This data is then transferred to advanced machining tools like CNC mills and EDM machines. These machines sculpt the die’s components with extraordinary accuracy, often reaching tolerances measured in thousandths of an inch. The Artistry of Die Making While the engineering aspect is paramount, die making also encompasses an artistic dimension. Experienced tool and die makers bring intuition and creativity to the process. They understand the nuances of metal behavior, heat treatment, and material selection, infusing a level of craftsmanship that transforms raw materials into functional works of art. Die makers must consider a plethora of factors, from the metal’s elasticity to the intricacies of the part’s geometry. Achieving the perfect balance between form and function requires both technical expertise and an artistic touch. Challenges and Innovations The evolution of metal stamping dies is a testament to human ingenuity. As industries demand more complex and efficient solutions, die makers and engineers rise to the challenge. Advanced simulation techniques allow for virtual testing of dies before their physical creation, reducing costly trial and error. Materials science also plays a crucial role. Researchers continually develop new tool steels and coatings that enhance the die’s durability, reducing wear and tear during the stamping process. This innovation extends the lifespan of dies and ensures consistent product quality over time. The Impact on Manufacturing Metal stamping dies have a profound impact across various industries. From automotive components to consumer electronics, many products we encounter daily owe their existence to this precise and efficient manufacturing method. The consistency and speed offered by metal stamping would be unattainable without the mastery of die making. Conclusion In the realm of manufacturing, where precision meets artistry, metal stamping dies stand as a testament to human achievement. These unassuming tools embody the fusion of cutting-edge engineering and timeless craftsmanship. As industries continue to advance, metal stamping dies will undoubtedly evolve, pushing the boundaries of what is possible and ensuring that the products of tomorrow are shaped with the same dedication and innovation as those of today.