Introduction

In the realm of modern manufacturing, thermoplastic injection molds have emerged as a pivotal technology, revolutionizing the production of various consumer and industrial products. This innovative technique offers unparalleled precision, efficiency, and versatility in creating complex shapes and structures. This article delves into the advancements and significance of thermoplastic injection molds, shedding light on their diverse applications and the benefits they bring to industries worldwide.

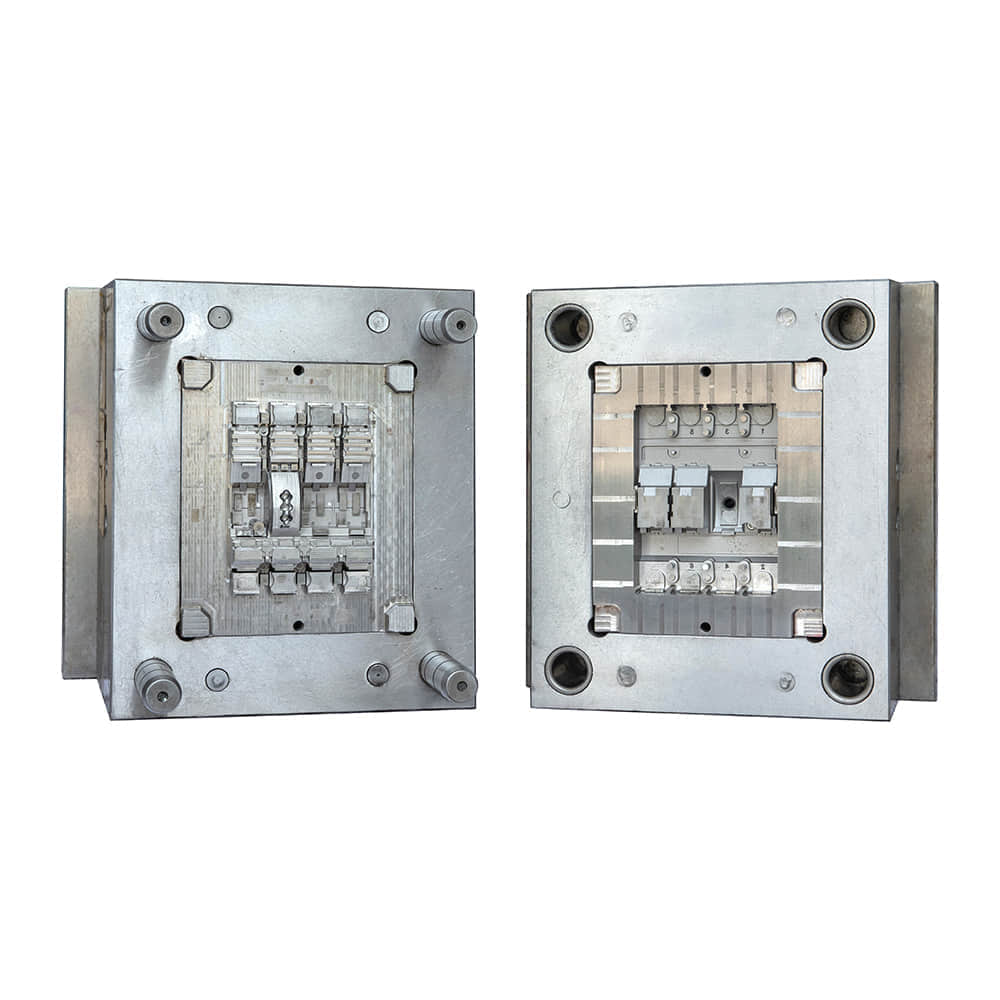

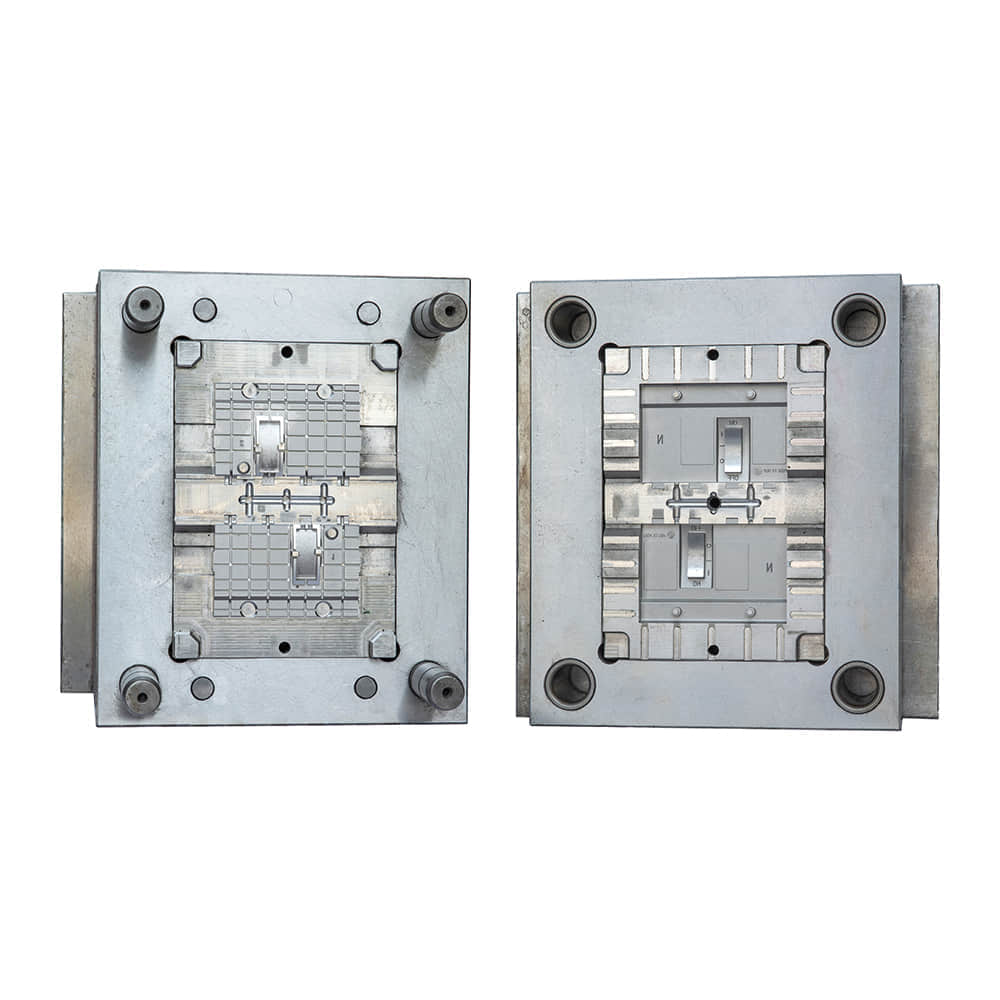

The Evolution of Thermoplastic Injection Molds The history of thermoplastic injection molds dates back to the mid-20th century when the concept of injecting molten plastic into a mold cavity gained traction. Over the decades, significant technological advancements have refined this process, making it an indispensable tool for mass production. Today, computer-aided design (CAD) software, along with computer numerical control (CNC) machining, enables the creation of highly detailed and intricate mold designs, pushing the boundaries of what is achievable. Precision and Complexity Redefined One of the standout advantages of thermoplastic injection molds is their ability to produce intricate and highly detailed products with exceptional precision. The molds themselves are crafted with meticulous accuracy, allowing for the replication of complex features down to micrometer scales. This level of precision has found its way into industries like electronics, where miniature components with exacting specifications are in high demand. Moreover, the consistent quality achieved through injection molding ensures minimal defects and deviations in the final products. Versatility in Material and Design Thermoplastic injection molds are renowned for their adaptability to a wide range of thermoplastic materials. This versatility, coupled with advancements in material science, empowers manufacturers to choose the ideal material for a specific application, whether it’s for its mechanical properties, resistance to heat and chemicals, or aesthetic qualities. From medical devices to automotive components, this flexibility in material selection has expanded the horizons of what can be manufactured using injection molds. Efficiency and Cost-Effectiveness In an era where efficiency is paramount, thermoplastic injection molds shine. The automated nature of the process, once the mold design is perfected, ensures swift and consistent production cycles. The rapid cooling and solidification of molten plastic within the mold cavity minimize production time, making it an ideal choice for high-volume manufacturing. Additionally, the ability to create complex shapes in a single step eliminates the need for multiple manufacturing stages, reducing overall production costs and material wastage. Sustainability and Waste Reduction As the world places greater emphasis on sustainable practices, thermoplastic injection molds offer a greener alternative in the manufacturing landscape. The precision-driven process generates minimal scrap material, and any waste that is produced can often be recycled and reused. Moreover, the efficiency of injection molding leads to energy savings over traditional manufacturing methods, contributing to a reduced carbon footprint. Conclusion Thermoplastic injection molds have undoubtedly transformed the way products are manufactured across industries. From their humble beginnings to the current era of advanced CAD designs and versatile material options, these molds exemplify precision, efficiency, and sustainability. As technology continues to advance, it is exciting to contemplate the future possibilities that thermoplastic injection molds will unlock, further pushing the boundaries of innovation and shaping our world in remarkable ways.