Introduction

In the realm of manufacturing and production, innovation is a constant driving force, and the field of thermoplastic injection molding is no exception. Thermoplastic injection molds have revolutionized the way products are manufactured, enabling the creation of intricate and precise components with efficiency and accuracy. This article delves into the advancements that have shaped the world of thermoplastic injection molds, highlighting their significance and the benefits they bring to various industries.

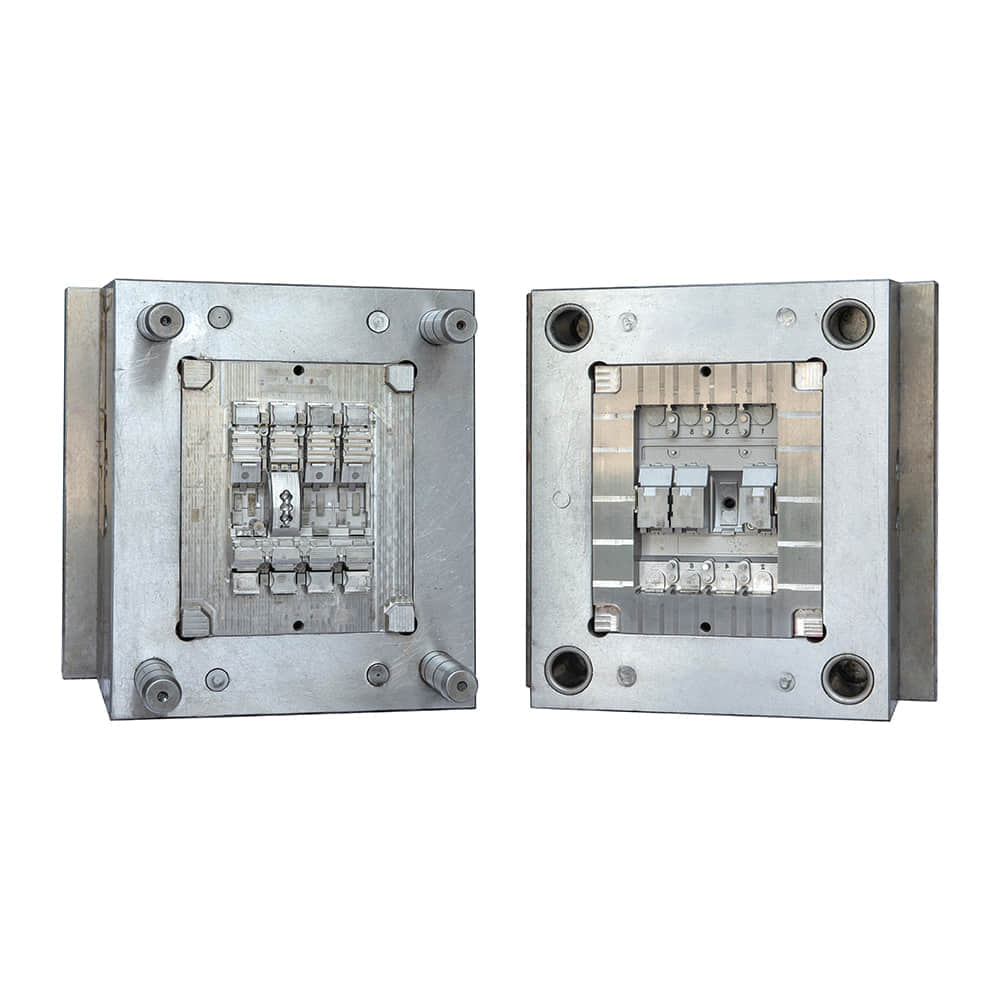

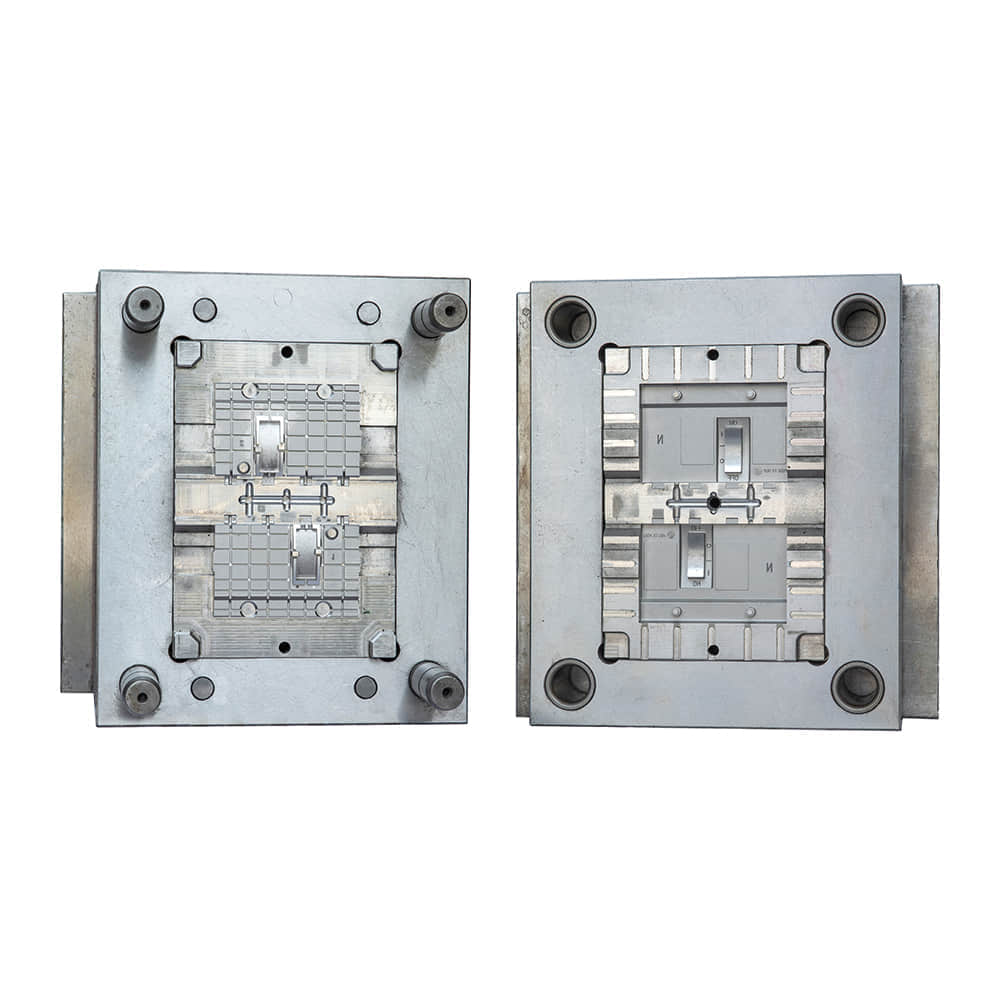

Evolution of Thermoplastic Injection Molds Thermoplastic injection molding has come a long way since its inception. Early molds were rudimentary, and the process was limited in terms of complexity and materials. However, with advancements in engineering, materials science, and manufacturing technology, injection molds have undergone a remarkable transformation. Modern molds are designed using cutting-edge computer-aided design (CAD) software, allowing for intricate designs and precise specifications. Precision and Complexity One of the standout features of thermoplastic injection molds is their ability to create intricate and complex geometries with unparalleled precision. This capability is especially crucial in industries such as aerospace, automotive, and electronics, where components with intricate designs and tight tolerances are required. The molds are crafted with extreme precision, ensuring that each product is consistent in quality and adherence to specifications. Material Versatility Advancements in materials science have expanded the range of thermoplastics that can be utilized in injection molding. From traditional polymers to specialized, high-performance materials, the options are vast. This versatility allows manufacturers to choose the ideal material for each application, whether it’s a consumer product requiring aesthetic appeal or an industrial part demanding robust mechanical properties. Faster Production Cycles In the world of manufacturing, time is often of the essence. Thermoplastic injection molds have undergone improvements that have drastically reduced production cycles. Automation, robotics, and enhanced mold cooling systems have all contributed to faster mold filling and cooling times. This not only increases overall production efficiency but also reduces energy consumption and costs. Sustainability and Waste Reduction As global awareness of environmental issues grows, industries are under pressure to adopt sustainable practices. Thermoplastic injection molding aligns with these goals by minimizing waste. With the use of advanced simulation tools, manufacturers can optimize mold designs, reduce material wastage, and minimize the need for post-processing. Furthermore, the recyclability of many thermoplastics contributes to a more environmentally friendly production process. Customization and Iterative Design In today’s fast-paced market, customization and rapid iteration are key to staying competitive. Thermoplastic injection molds facilitate quick design changes and iterations without the need for extensive tooling modifications. This is particularly advantageous in industries like consumer electronics, where product designs evolve rapidly. Cost-Efficiency The combination of precision, speed, and material versatility in thermoplastic injection molding translates to cost-efficiency. The reduced need for secondary operations, the ability to produce complex parts in a single operation, and the minimization of defects all contribute to lowering overall production costs. Conclusion Thermoplastic injection molds have evolved into a cornerstone of modern manufacturing, enabling the creation of intricate, high-quality components with efficiency and accuracy. With advancements in design, materials, and technology, these molds continue to shape various industries, from automotive and electronics to healthcare and consumer goods. As innovation in the field of thermoplastic injection molding persists, we can anticipate even more remarkable capabilities, furthering the impact of this technology on the way we create products.