Introduction

In the realm of modern manufacturing, thermoplastic injection molds have emerged as a cornerstone technology, revolutionizing the production of a wide range of consumer and industrial products. Leveraging the remarkable properties of thermoplastics, this innovative manufacturing process offers versatility, precision, and efficiency like never before. In this article, we will delve into the world of thermoplastic injection molds, exploring their advancements, applications, and the impact they have on various industries.

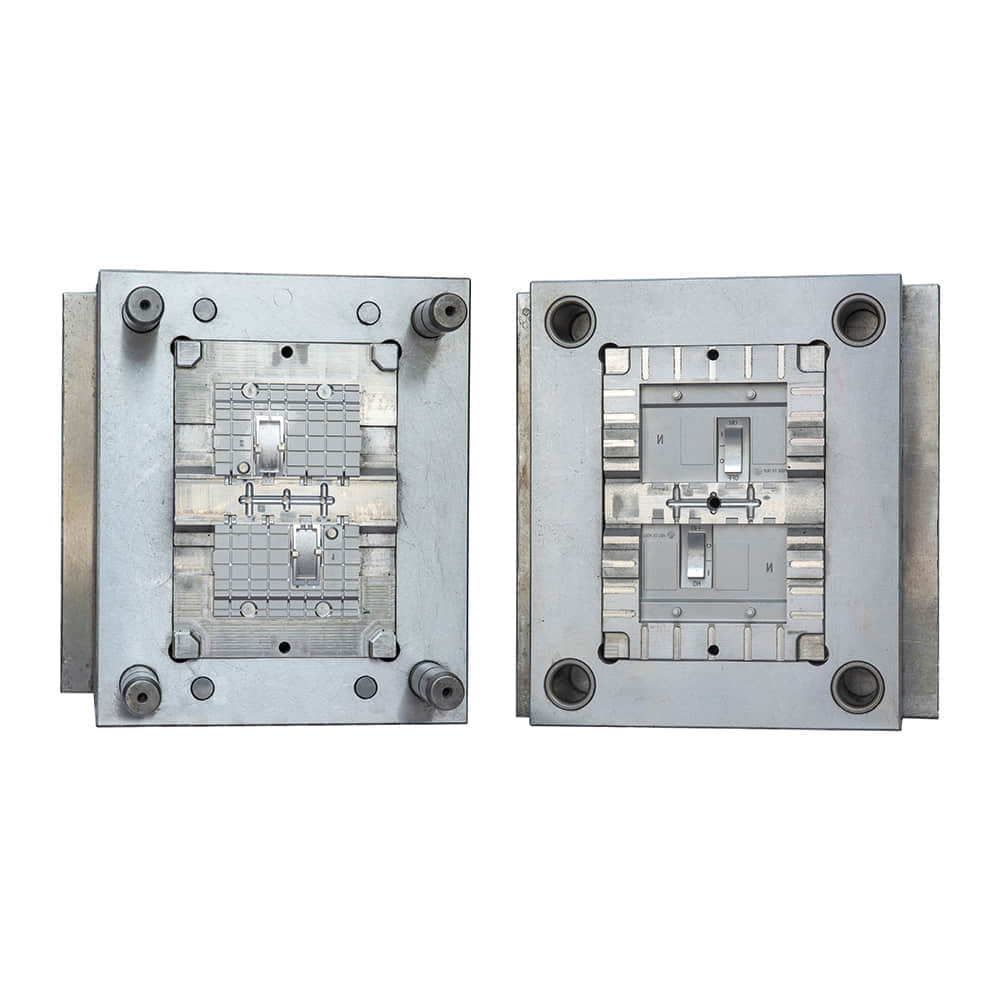

The Fundamentals of Thermoplastic Injection Molds Thermoplastic injection molding involves the creation of complex shapes and structures by injecting molten thermoplastic materials into a precisely crafted mold. The mold, usually made from metal, is designed to impart the desired shape and features to the final product. Once the molten plastic is injected into the mold, it cools and solidifies rapidly, taking on the form of the mold. This process allows for the efficient and consistent production of high-quality parts with intricate details. Advancements in Thermoplastic Injection Molds Recent years have witnessed significant advancements in thermoplastic injection molding technology, enhancing its capabilities and broadening its applications. One key advancement is the development of advanced mold materials, such as hardened steels and ceramics, which offer improved durability and extended tool life. Additionally, the integration of computer simulations and modeling techniques has enabled manufacturers to optimize mold designs before physical production, reducing the need for costly trial and error. Furthermore, the advent of multi-material and multi-color injection molding has opened doors to even more creative product designs. This allows for the incorporation of various materials or colors within a single mold cycle, resulting in products with enhanced functionality and aesthetics. These advancements collectively contribute to faster production cycles, reduced waste, and ultimately, lower costs. Applications across Industries The applications of thermoplastic injection molds span across a multitude of industries, each benefiting from the unique advantages this technology offers. Automotive Industry:Thermoplastic injection molding plays a pivotal role in the automotive sector, enabling the production of lightweight yet durable components. From interior panels to under-the-hood parts, this technology ensures precise manufacturing and consistency in performance. Consumer Electronics:The intricate designs and small form factors of modern electronic devices are made possible by thermoplastic injection molds. This process facilitates the creation of intricate casings, connectors, and buttons with exceptional detail. Medical Equipment:In the medical field, precision and hygiene are paramount. Thermoplastic injection molds provide a means to create intricate and sterilizable components used in medical devices, ensuring both patient safety and high-quality healthcare. Packaging:The packaging industry benefits from the speed and efficiency of thermoplastic injection molding for producing various types of packaging containers, caps, and closures. Toys and Leisure Products:Many everyday items, such as toys and leisure products, owe their affordability and intricate designs to thermoplastic injection molds. This technology allows for mass production of safe and engaging products for all age groups. Conclusion Thermoplastic injection molding stands as a testament to the continuous evolution of manufacturing techniques. Its ability to produce complex, high-quality parts with efficiency has significantly impacted various industries, shaping the way products are designed and manufactured. As advancements continue and new materials are introduced, the future of thermoplastic injection molds looks promising, holding the potential to further redefine the possibilities of modern manufacturing.