In the industrial sector, safety and reliability are paramount. One critical component that ensures these attributes is the explosion-proof electric butterfly valve. This specialized valve is designed to control the flow of fluids in systems that are potentially hazardous, including those that handle flammable or explosive materials. For industries reliant on such equipment, finding a trustworthy OEM (Original Equipment Manufacturer) for explosion-proof electric butterfly valves is essential. This article delves into the features and significance of these valves, the role of OEM manufacturers, and what to consider when choosing a supplier.

Understanding Explosion-Proof Electric Butterfly Valves

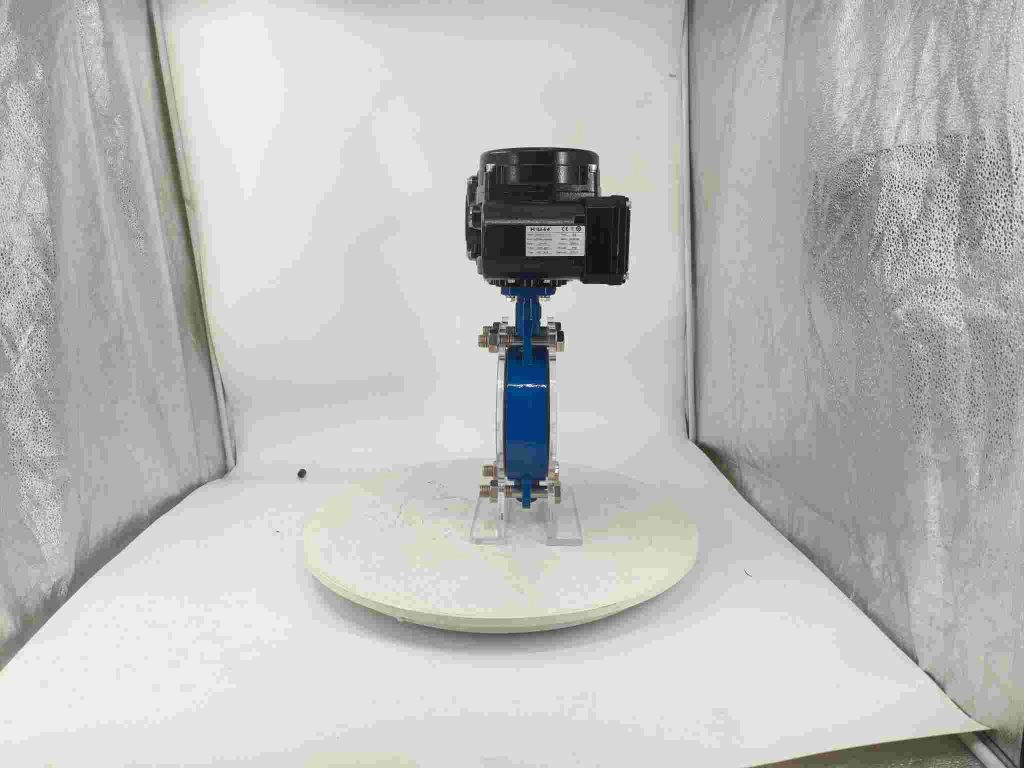

An explosion-proof electric butterfly valve is a device that combines the functionalities of a butterfly valve with electric actuation and explosion-proof features. The butterfly valve itself is a quarter-turn valve with a disk that rotates to open or close the flow of fluids. This design allows for precise control and quick operation, making it ideal for applications requiring frequent adjustments. The explosion-proof aspect of these valves is critical in environments where there is a risk of ignition or explosion. The valve’s housing is designed to withstand and contain any potential explosions, preventing the spread of flames and protecting both personnel and equipment. This feature is particularly important in industries such as petrochemicals, pharmaceuticals, and mining, where hazardous materials are common.