In the realm of modern manufacturing, precision and efficiency are paramount. One key player in achieving these objectives is the Metal Stamping Die Manufacturer. With expertise rooted in engineering and innovation, these manufacturers provide the vital tools that enable the production of intricate metal components used in various industries. This article delves into the world of metal stamping die manufacturing, highlighting its significance, processes, and contributions to the industrial landscape.

The Heart of Precision Engineering

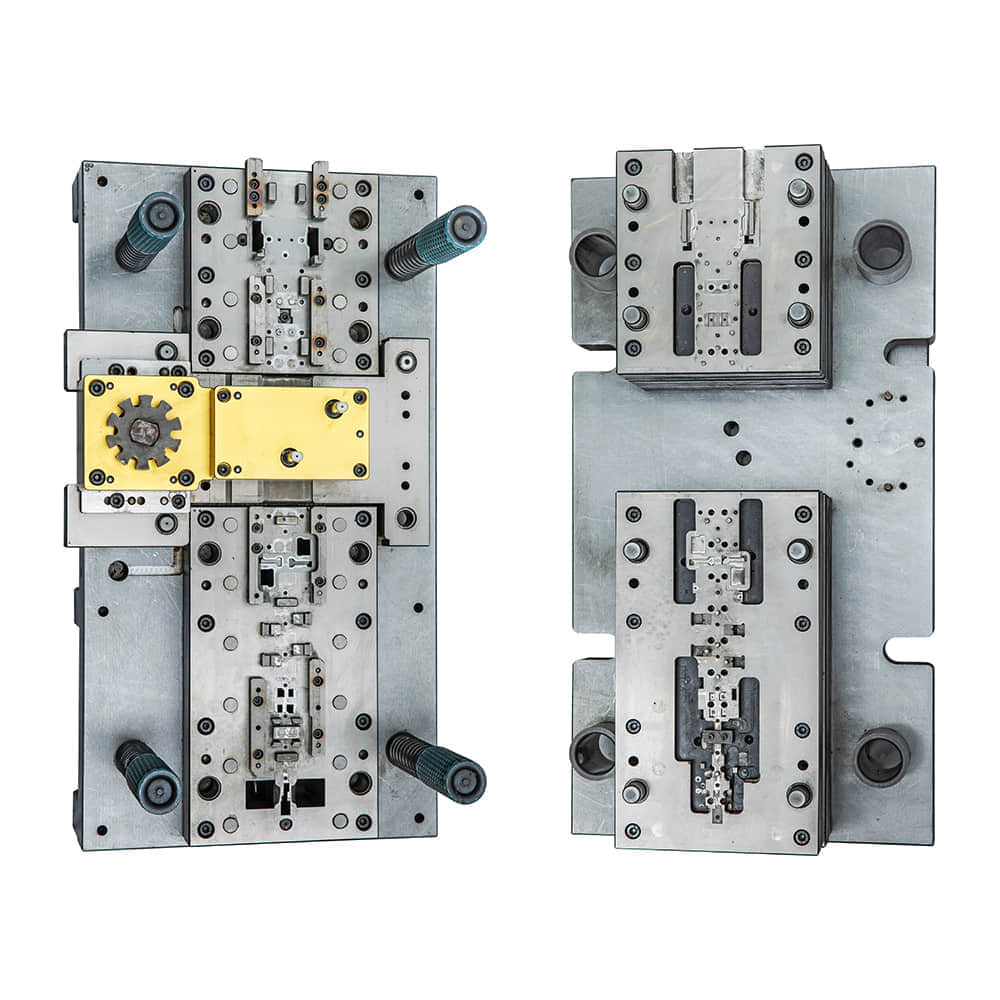

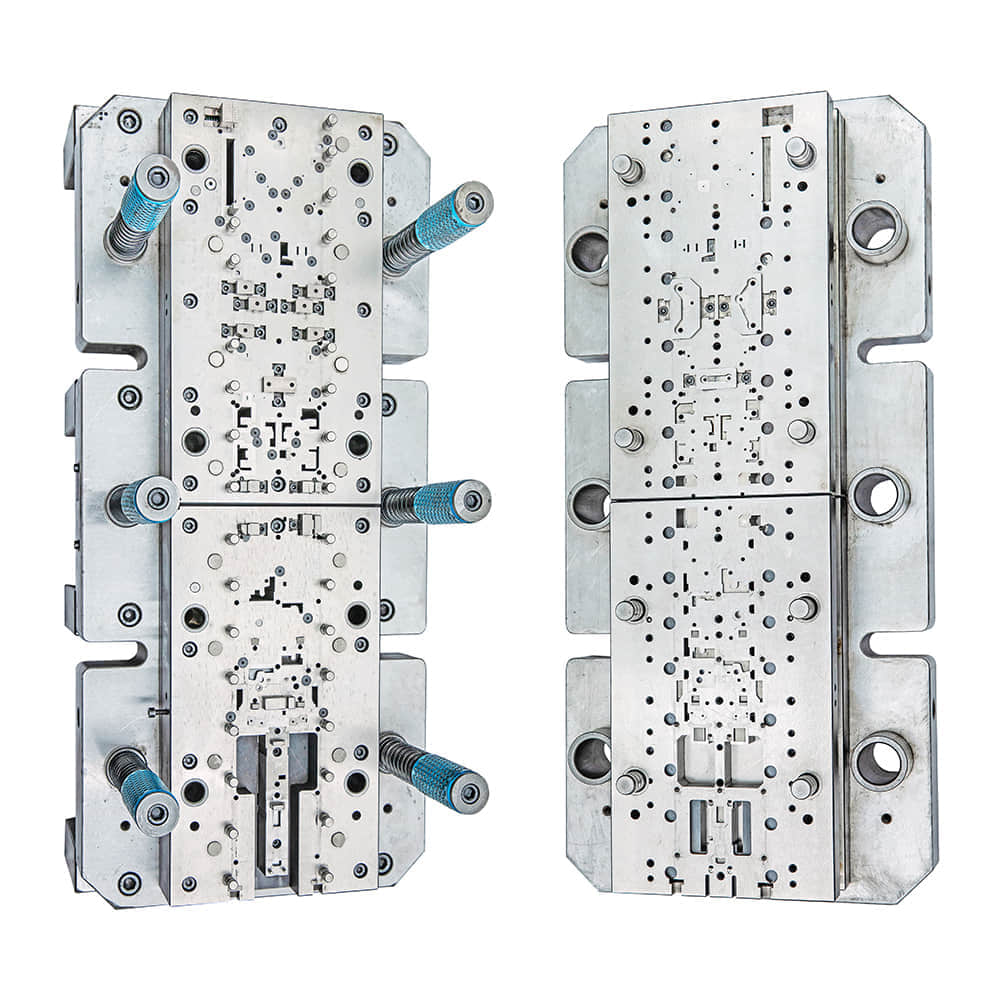

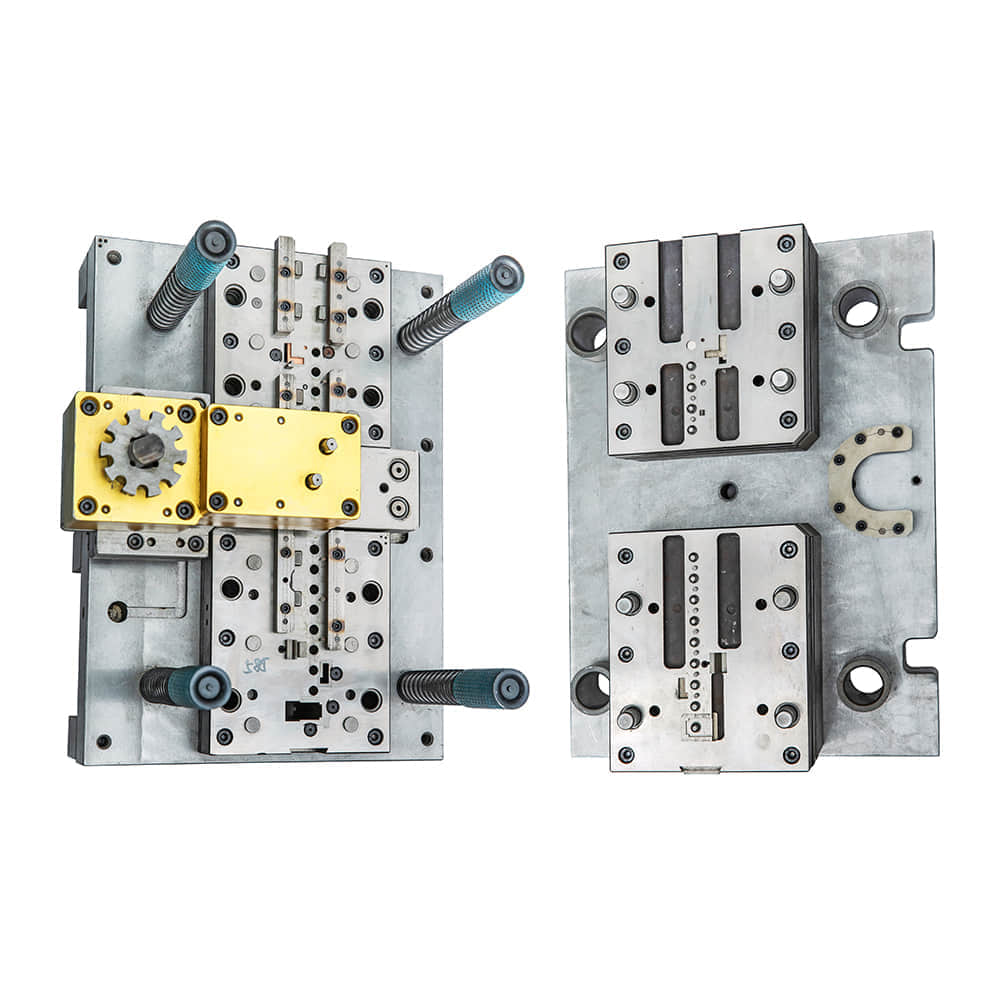

Metal stamping die manufacturers are the architects behind the precision engineering that drives many industrial processes. These manufacturers design and fabricate the dies, tools, and molds that shape raw metal sheets into finely detailed components. These components, ranging from automotive parts to consumer electronics, require exact specifications and tolerances. A metal stamping die must be meticulously crafted to ensure that each piece it produces adheres to these stringent requirements. The Art and Science of Die Manufacturing The process of creating metal stamping dies is a blend of art and science. It starts with in-depth design and engineering, where skilled professionals utilize computer-aided design (CAD) software to conceptualize the die’s geometry. Factors such as material characteristics, anticipated production volume, and intricate design details are considered during this phase. Once the design is finalized, the manufacturing process commences. High-precision machining tools, such as CNC mills and wire EDM (Electrical Discharge Machining) machines, are employed to carve out the die’s components with remarkable accuracy. These components must fit together seamlessly to ensure flawless metal forming. Innovation and Technological Integration In recent years, innovation has propelled the metal stamping die manufacturing industry forward. Advanced technologies like computer simulation software aid in predicting how the metal will behave during the stamping process, allowing manufacturers to optimize their designs before physically crafting the dies. This reduces costly trial-and-error iterations and accelerates time-to-market for new products. Moreover, automation has found its way into this sector. Automated systems can handle repetitive tasks with minimal human intervention, increasing efficiency, consistency, and overall output. This integration of technology not only enhances productivity but also ensures that the manufactured components meet the highest quality standards. Driving Industries Forward The contributions of metal stamping die manufacturers are deeply ingrained in various industries. The automotive sector relies on these manufacturers to produce precision parts that contribute to vehicle safety and performance. In the electronics industry, metal stamped components form the basis of countless devices, from smartphones to industrial machinery. Even the aerospace industry benefits from metal stamping, as components must meet rigorous standards to ensure the safety of air travel. Quality Assurance as a Cornerstone Quality assurance stands as a cornerstone of metal stamping die manufacturing. Manufacturers employ rigorous testing and inspection protocols to verify that the produced components match the desired specifications. This commitment to quality extends the lifespan of the metal stamping dies themselves, which can be used for hundreds of thousands, if not millions, of production cycles with proper maintenance. Environmental Considerations As industries increasingly emphasize sustainability, metal stamping die manufacturers are also adapting. Efforts to minimize waste, reduce energy consumption, and employ eco-friendly materials are becoming more prevalent. By incorporating environmentally conscious practices, these manufacturers contribute to a greener manufacturing ecosystem. Conclusion The role of a metal stamping die manufacturer transcends the act of crafting tools; it involves shaping the present and future of industries around the world. Through precision engineering, technological integration, and a commitment to quality, these manufacturers enable the production of essential components that drive innovation across diverse sectors. As manufacturing continues to evolve, metal stamping die manufacturers remain integral to the process, working diligently behind the scenes to turn sheets of metal into the building blocks of modern life.