A Cold Water Solenoid Valve is an essential component in many modern water control systems. As a type of electromechanical valve, it allows for the precise regulation of cold water flow in a wide range of appliances and industrial applications. This article explores the working principle, applications, and advantages of cold water solenoid valves, highlighting their significance in various sectors.

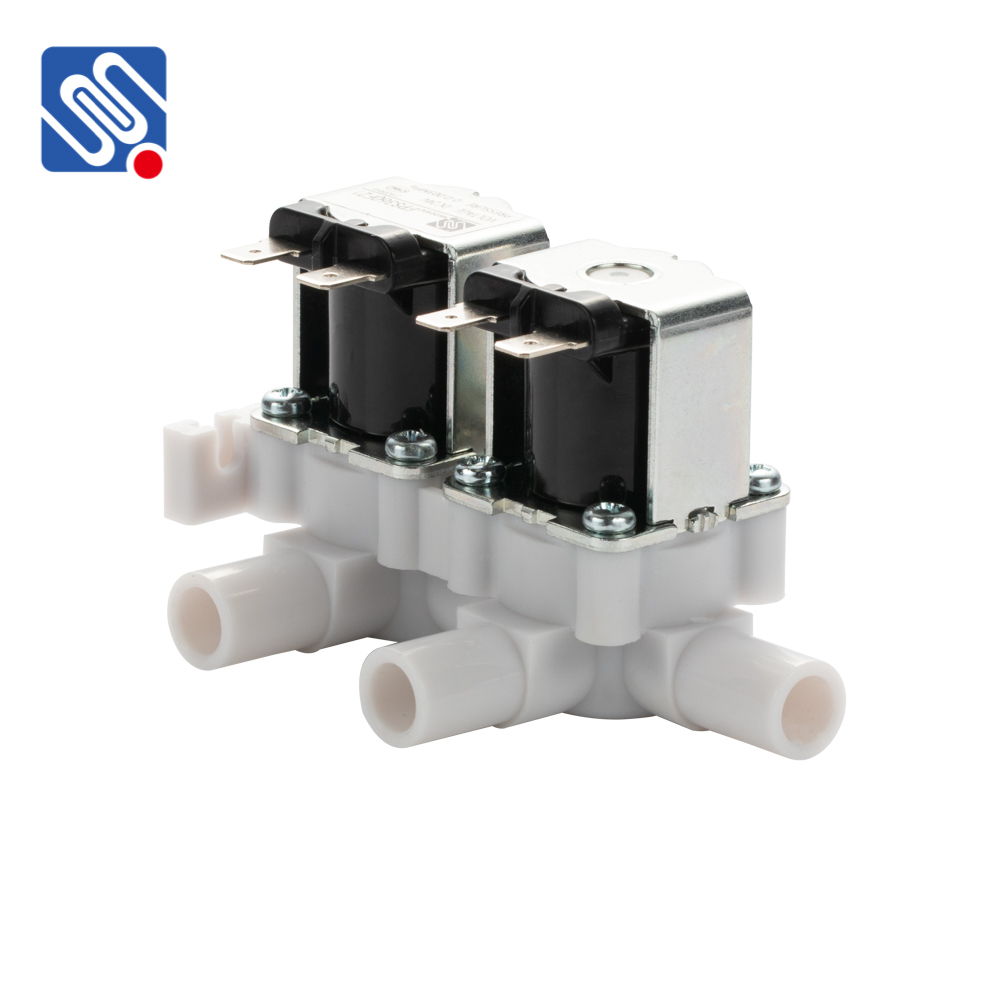

Working Principle of Cold Water Solenoid Valves Cold Water Solenoid Valves operate based on the electromagnetic principle. They consist of an electromagnetic coil, a valve body, a plunger, and a spring. When electrical current passes through the coil, it generates a magnetic field that moves the plunger inside the valve. This movement either opens or closes the valve depending on the design, regulating the flow of cold water. There are two common types of solenoid valves: normally closed (NC) and normally open (NO). In a normally closed valve, the plunger is held in the closed position by a spring when there is no power, preventing water flow. When the solenoid is energized, the magnetic force lifts the plunger, allowing water to flow. In contrast, normally open valves allow water to flow when de-energized, and the solenoid action closes the valve when powered.