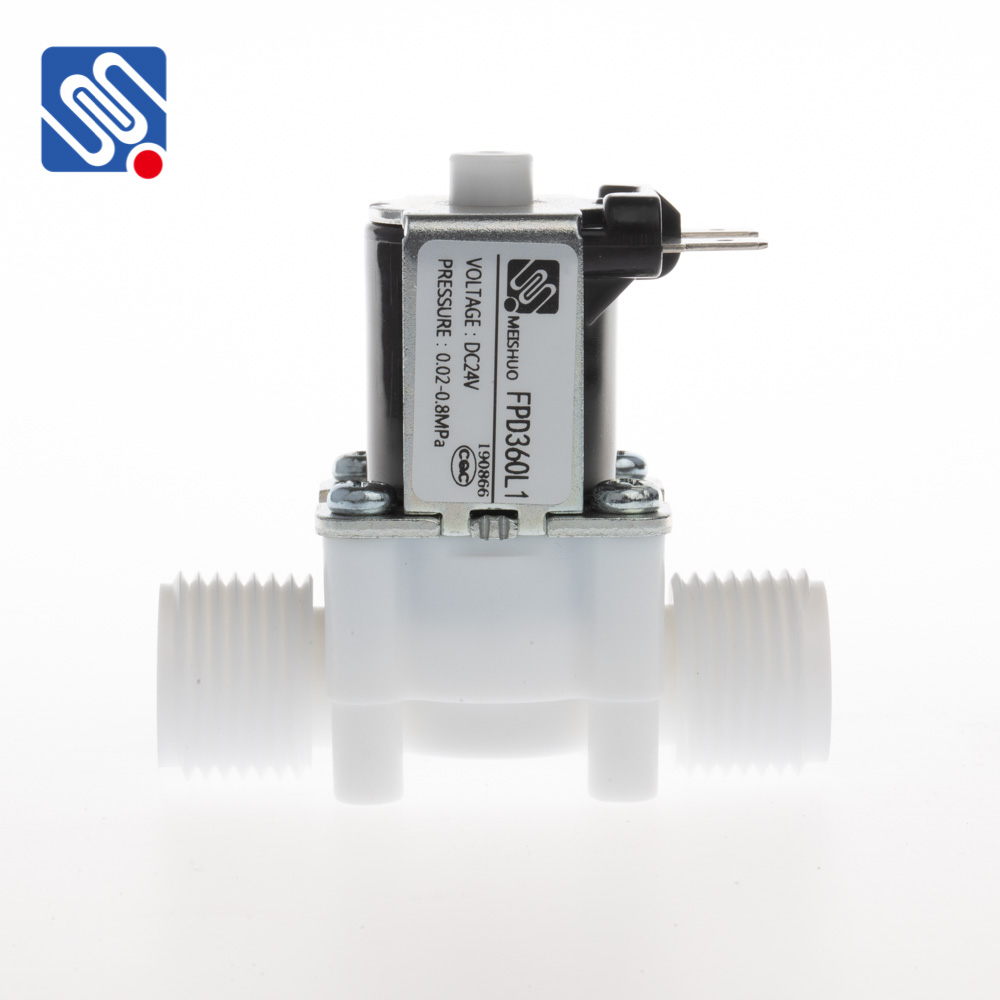

In the rapidly evolving industrial sector, solenoid valves have become essential components for controlling fluid flow in a variety of applications. Among the different types of solenoid valves, plastic solenoid valves have gained significant popularity due to their excellent resistance to corrosion, lightweight design, and cost-effectiveness. As demand for these valves continues to grow across industries such as water treatment, irrigation, HVAC, and chemical processing, China has become a global leader in the production and supply of plastic solenoid valves. With a large number of manufacturers catering to diverse industrial needs, China remains at the forefront of innovation in this sector.

Growing Demand for Plastic Solenoid Valves Plastic solenoid valves are used to regulate the flow of fluids in a wide range of systems. They are particularly valued for their resistance to corrosion, which makes them ideal for applications where the fluid being controlled is harsh or corrosive. Common materials used in the manufacturing of plastic solenoid valves include PVC (Polyvinyl Chloride), PVDF (Polyvinylidene Fluoride), and PP (Polypropylene), all of which are known for their superior chemical resistance and durability. These characteristics make plastic solenoid valves highly suitable for industries such as water treatment, where they help control the flow of treated water, as well as in the chemical industry for controlling the flow of aggressive chemicals. Additionally, plastic solenoid valves are used in agricultural applications for irrigation systems and in HVAC (Heating, Ventilation, and Air Conditioning) systems for precise fluid control.