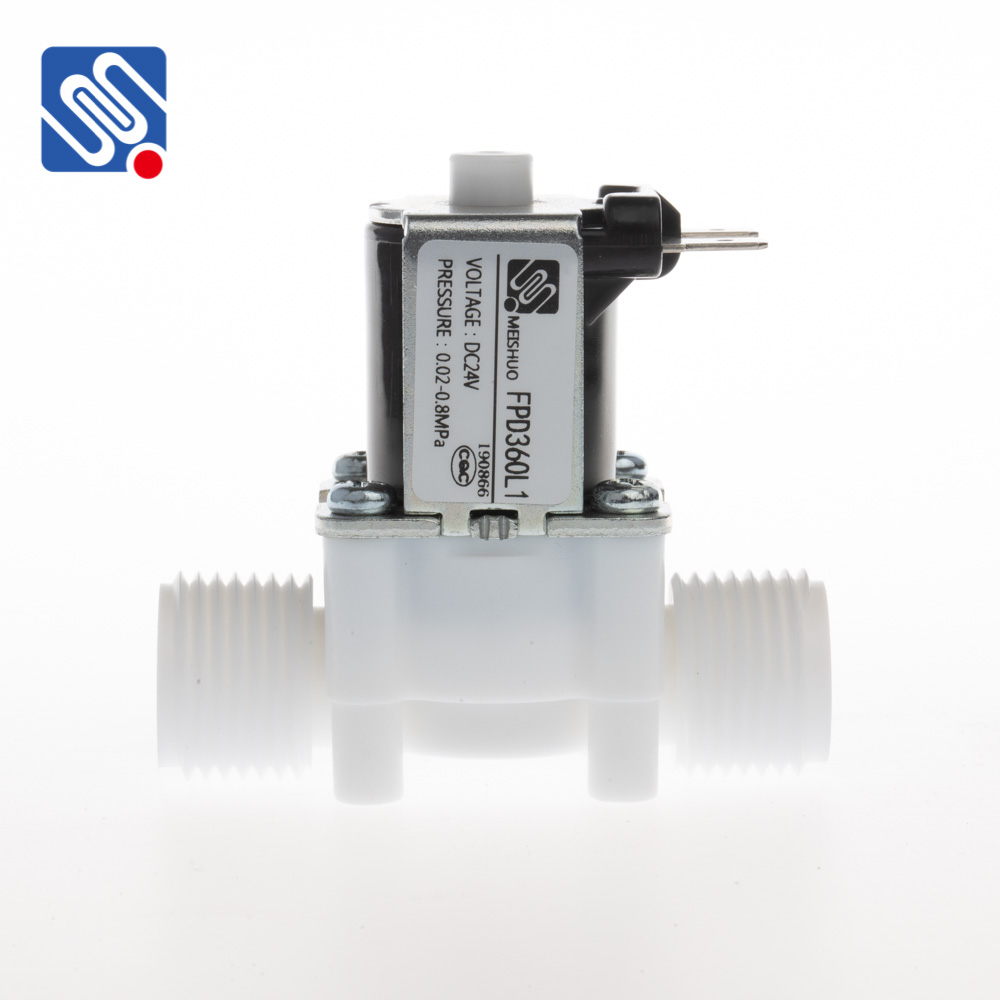

The plastic material is often preferred due to its resistance to corrosion, lightweight nature, and cost-effectiveness compared to metal solenoid valves. Common types of plastic materials used in solenoid valves include PVC (polyvinyl chloride), PP (polypropylene), PVDF (polyvinylidene fluoride), and other high-quality engineering plastics.

Key features of plastic solenoid valves include: Corrosion Resistance: Suitable for aggressive chemicals and harsh environments. Lightweight: Easier to install and handle compared to metal valves. Cost-Effective: Generally less expensive to manufacture and purchase. Durability: Long service life even in challenging environments. Some well-known Chinese manufacturers of plastic solenoid valves may also offer a variety of valve configurations, such as normally closed, normally open, and latching types, depending on the application. Are you looking for a specific supplier or more detailed information on these valves?