In the realm of manufacturing, China has firmly established itself as a global leader, consistently showcasing its prowess in various industries. One such industry that exemplifies China’s manufacturing excellence is the hardware mold manufacturing sector. With its emphasis on precision, innovation, and unwavering commitment to quality, China’s hardware mold manufacturers have carved out a prominent place on the international stage.

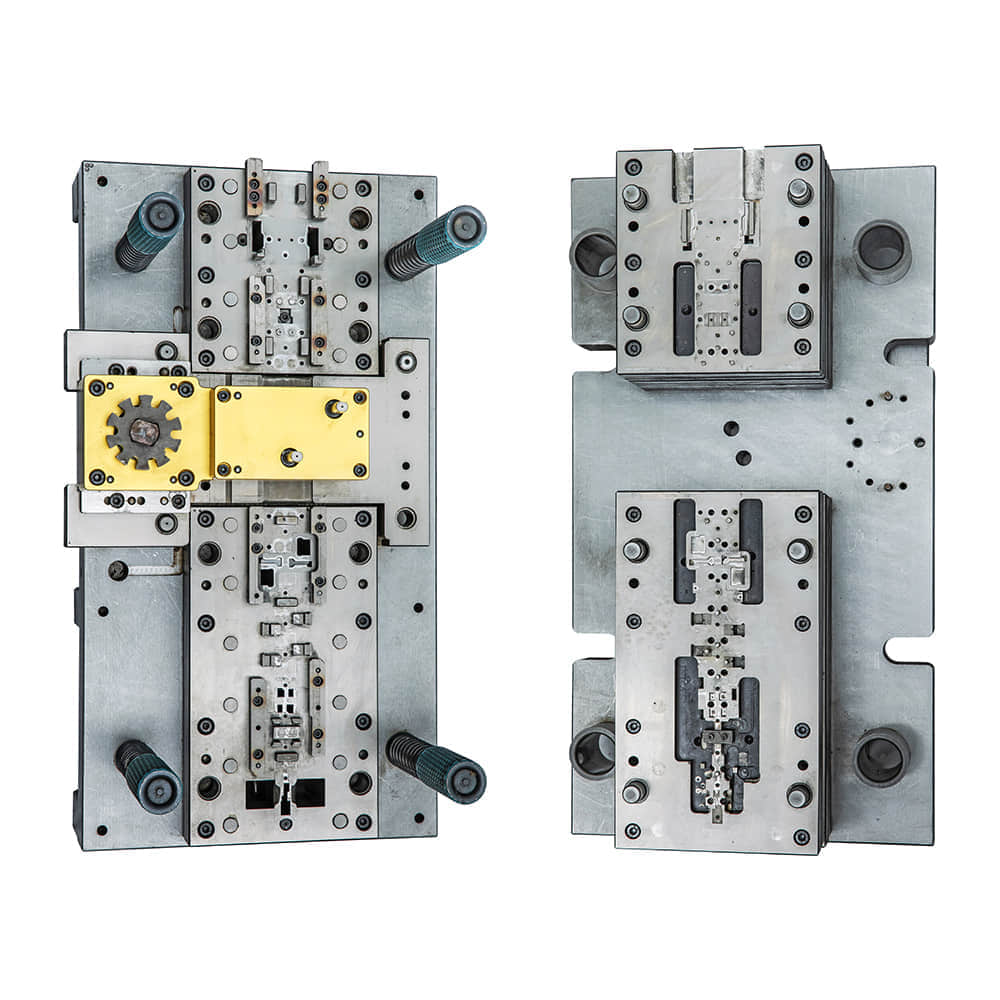

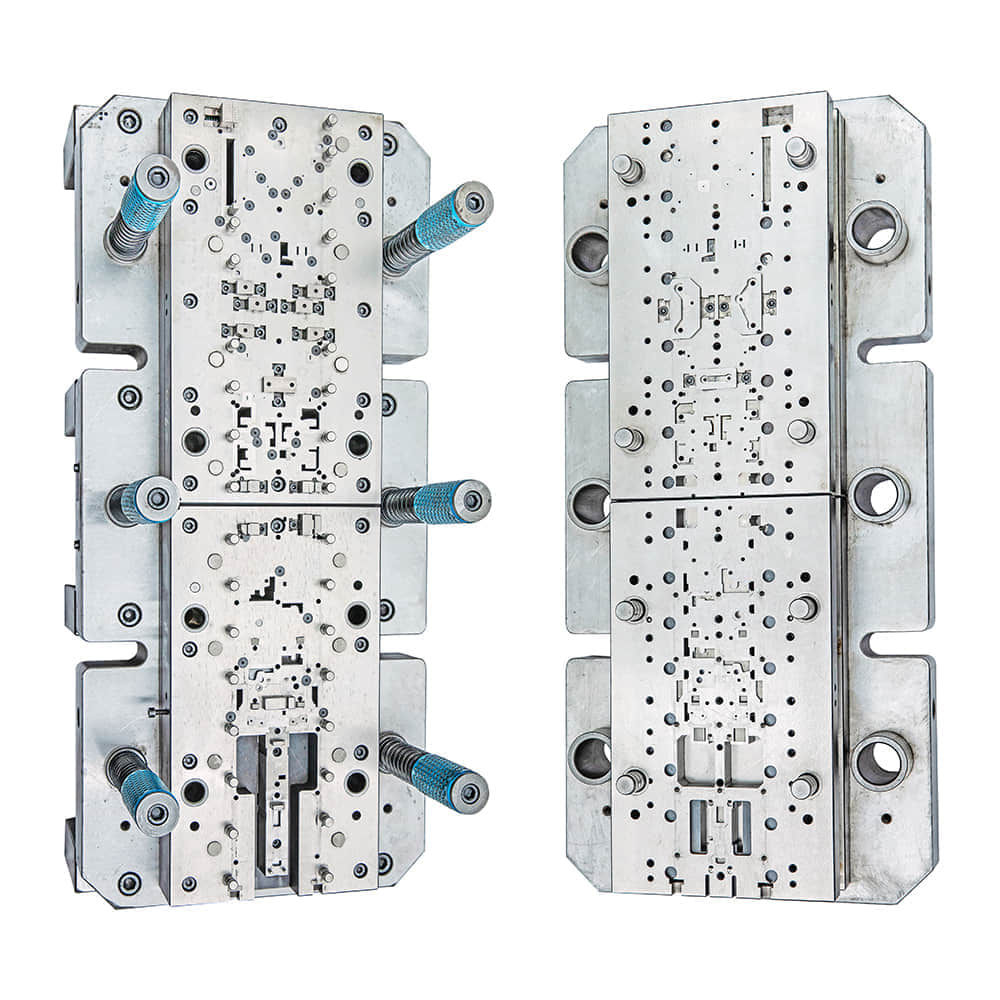

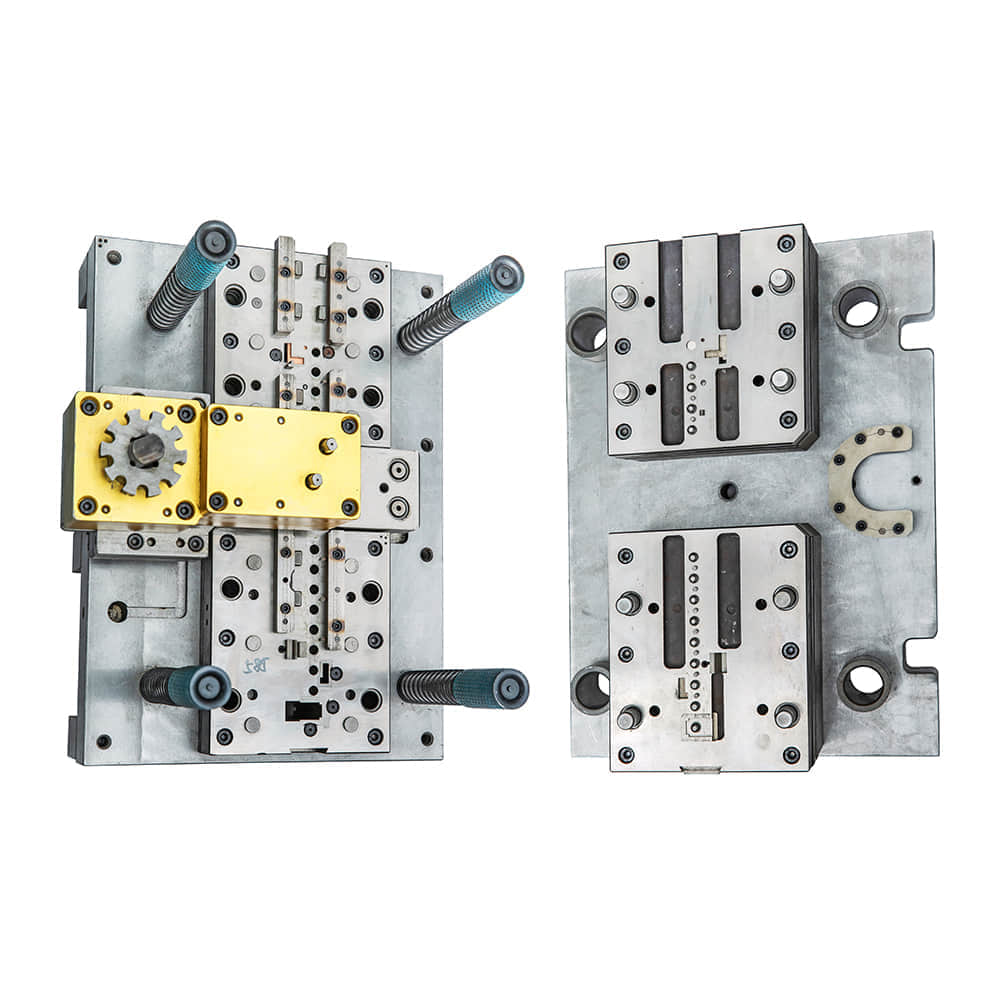

Precision is the cornerstone of China’s hardware mold manufacturing industry. The intricate and complex designs of modern products necessitate molds that can reproduce every detail with utmost accuracy. Chinese manufacturers have invested heavily in advanced technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to ensure that every mold produced meets the strictest precision standards. This dedication to precision is not only a testament to their technical expertise but also a reflection of their dedication to meeting the evolving needs of industries ranging from automotive to electronics.

Innovation has become synonymous with China’s approach to hardware mold manufacturing. The industry is marked by its proactive embrace of new technologies and methodologies. Additive manufacturing, commonly known as 3D printing, has revolutionized the way prototypes and molds are developed. Chinese manufacturers have adeptly incorporated 3D printing into their processes, allowing for rapid prototyping and reducing lead times. By staying at the forefront of technological advancements, China’s hardware mold manufacturers continue to push the boundaries of what is possible, providing their clients with innovative solutions that optimize production and efficiency. Quality reigns supreme in the competitive landscape of hardware mold manufacturing, and China stands tall in this aspect as well. Chinese manufacturers adhere to rigorous quality control processes at every stage of mold production. From the selection of materials to the final inspection, each step is meticulously executed to ensure that the molds meet the highest quality standards. This commitment to quality has earned China’s hardware mold manufacturers the trust and repeat business of clients from around the world. ISO certifications and other industry-specific accolades further validate their dedication to producing molds that stand the test of time. The global demand for precision-engineered products has driven China’s hardware mold manufacturers to continuously refine their skills and invest in their workforce. These manufacturers collaborate with educational institutions and technical training centers to nurture the next generation of skilled craftsmen. Apprenticeships and training programs not only pass down traditional techniques but also incorporate modern methodologies, creating a workforce that seamlessly merges time-honored practices with cutting-edge technologies. China’s hardware mold manufacturers have transcended their domestic borders to become key players in the international market. Their ability to produce molds that align with global standards while remaining cost-effective has garnered attention and respect across industries. As a result, China has become a sought-after destination for businesses seeking reliable partners in mold manufacturing. In conclusion, the story of China’s hardware mold manufacturing industry is one of precision, innovation, and quality. The industry’s unwavering dedication to producing molds that shape the products of today and tomorrow is a testament to China’s commitment to manufacturing excellence. As the global demand for precision-engineered products continues to rise, China’s hardware mold manufacturers are well-positioned to drive innovation, set new benchmarks for quality, and shape the future of manufacturing on a global scale.