China has rapidly evolved into a global powerhouse in various industries, and the hardware mold manufacturing sector is no exception. With its dedication to precision, innovation, and cost-efficiency, China has become a hub for hardware mold production, catering to diverse industries such as automotive, electronics, consumer goods, and more.

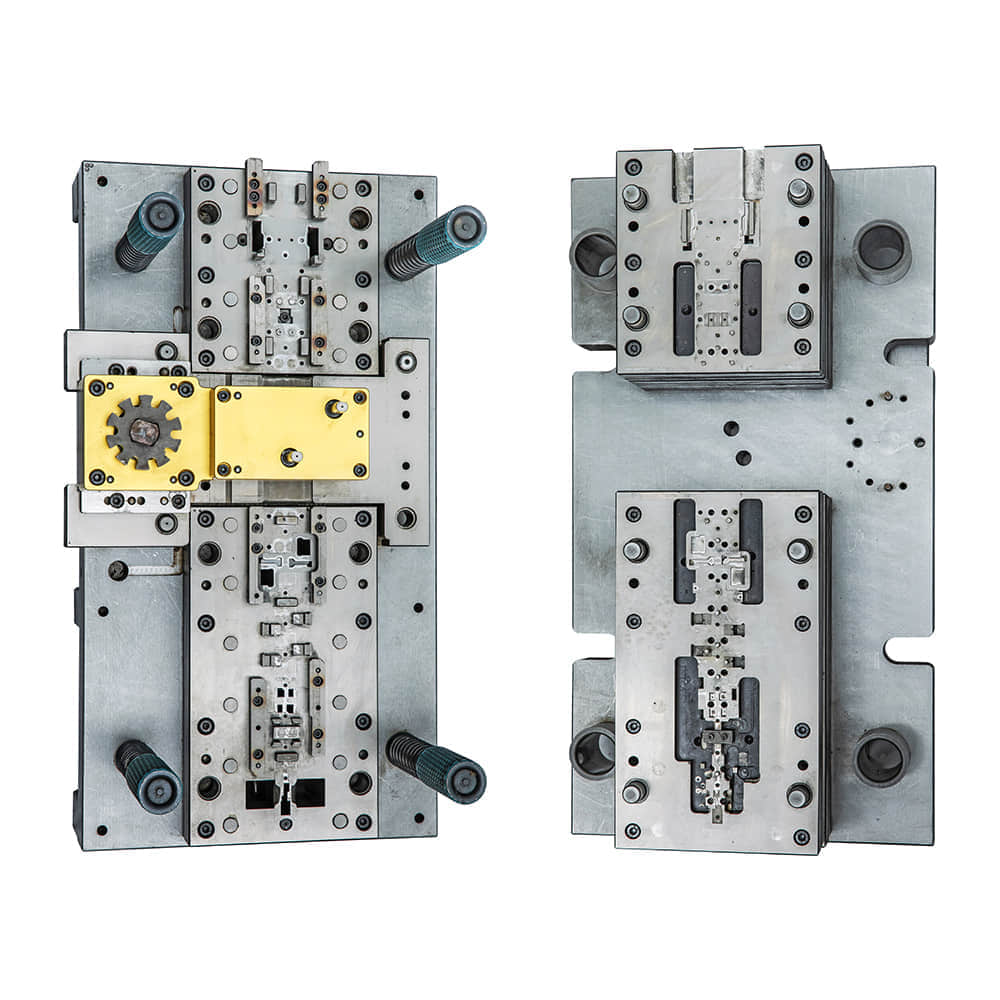

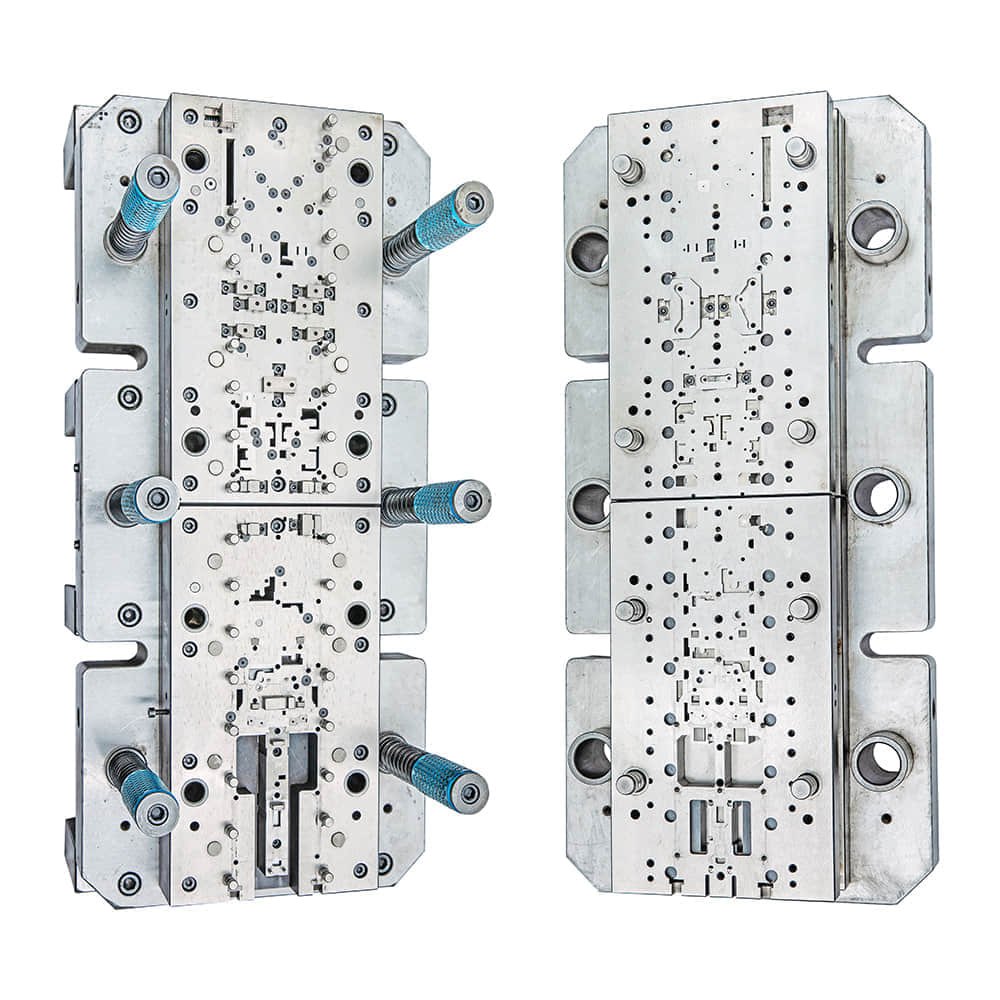

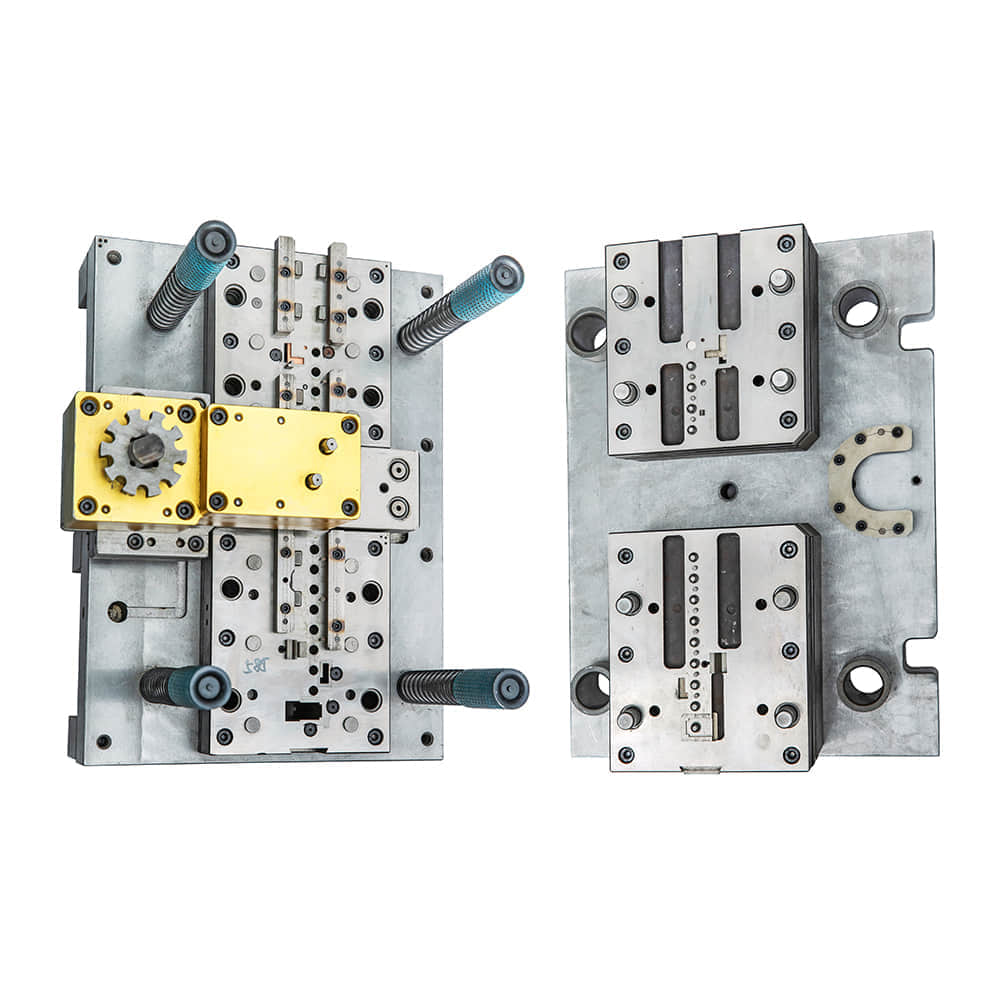

Precision lies at the heart of China’s hardware mold manufacturing prowess. The country boasts a robust infrastructure that supports advanced technologies, ensuring that the molds produced meet the tightest tolerances and specifications. China’s skilled workforce is trained to meticulously design and engineer molds that yield high-quality end products. From intricate components in electronic devices to large automobile parts, Chinese hardware mold manufacturers exhibit exceptional attention to detail, positioning themselves as leaders in the global market.

Innovation is another driving force behind China’s hardware mold manufacturing success story. To stay ahead in the competitive landscape, manufacturers consistently invest in research and development. This dedication has led to the adoption of cutting-edge techniques such as computer-aided design (CAD), computer-aided manufacturing (CAM), and even artificial intelligence (AI) in the mold-making process. These innovations not only enhance the accuracy of mold production but also accelerate the overall manufacturing timeline, giving businesses a crucial edge in their operations. One hallmark of China’s hardware mold industry is its adaptability to evolving market demands. Manufacturers in China understand that different industries require molds with varying specifications. The ability to swiftly pivot and tailor mold production according to these requirements sets Chinese manufacturers apart. Whether it’s a rapid shift in design, material, or production volume, China’s hardware mold industry rises to the challenge, serving as a reliable partner to businesses worldwide. Cost-efficiency has also been a key factor in China’s dominance in hardware mold manufacturing. The country offers competitive pricing without compromising on quality. Economies of scale, streamlined production processes, and access to cost-effective raw materials contribute to the attractive pricing structure. This makes China an ideal destination for businesses looking to optimize their production costs while obtaining top-notch molds. Environmental sustainability has gained prominence globally, and China’s hardware mold manufacturers are attuned to this trend. Many manufacturers are embracing greener practices by adopting eco-friendly materials, optimizing energy consumption, and minimizing waste in the production process. This commitment to sustainability not only aligns with international standards but also reflects a conscientious approach to responsible manufacturing. In conclusion, China’s hardware mold manufacturers have carved out a remarkable niche in the global manufacturing landscape. Their precision, innovation, adaptability, cost-efficiency, and sustainability practices contribute to their position as leaders in the industry. As China continues to invest in advanced technologies and refine its manufacturing processes, its hardware mold manufacturers are poised to play an increasingly pivotal role in shaping various industries worldwide.