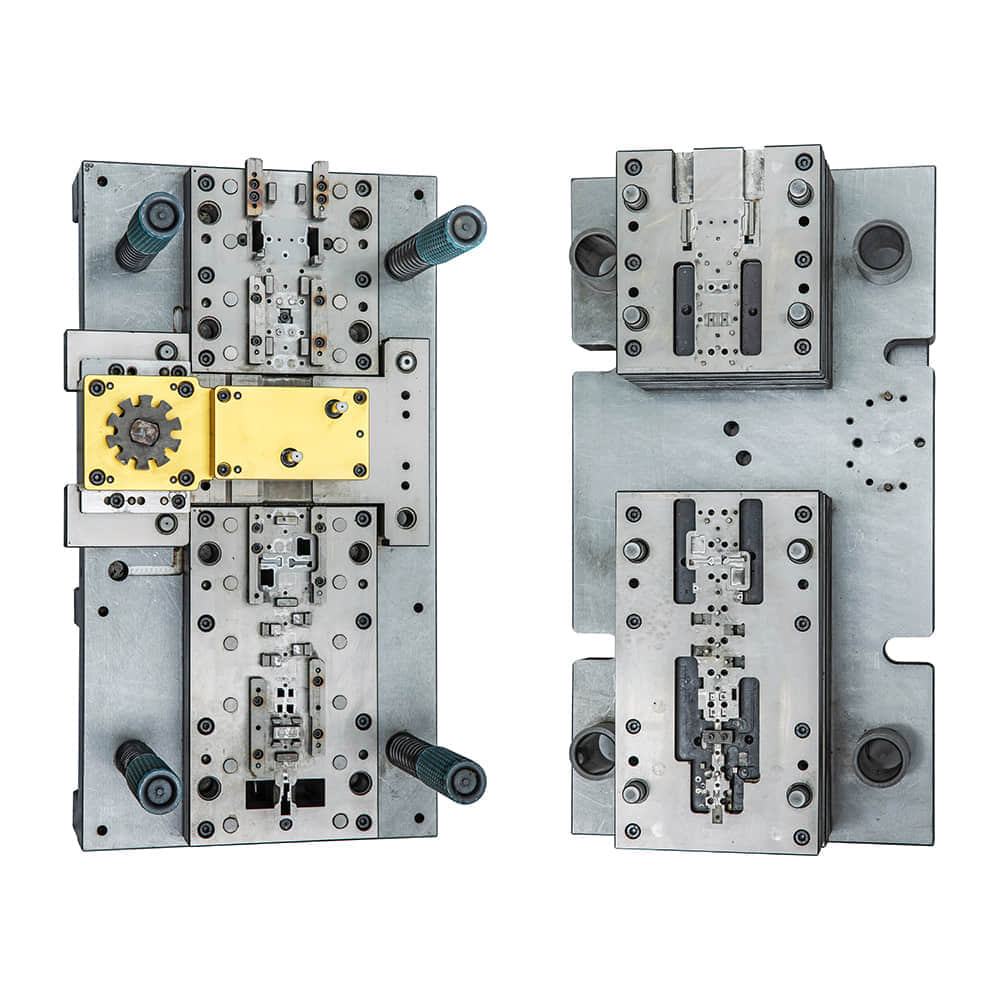

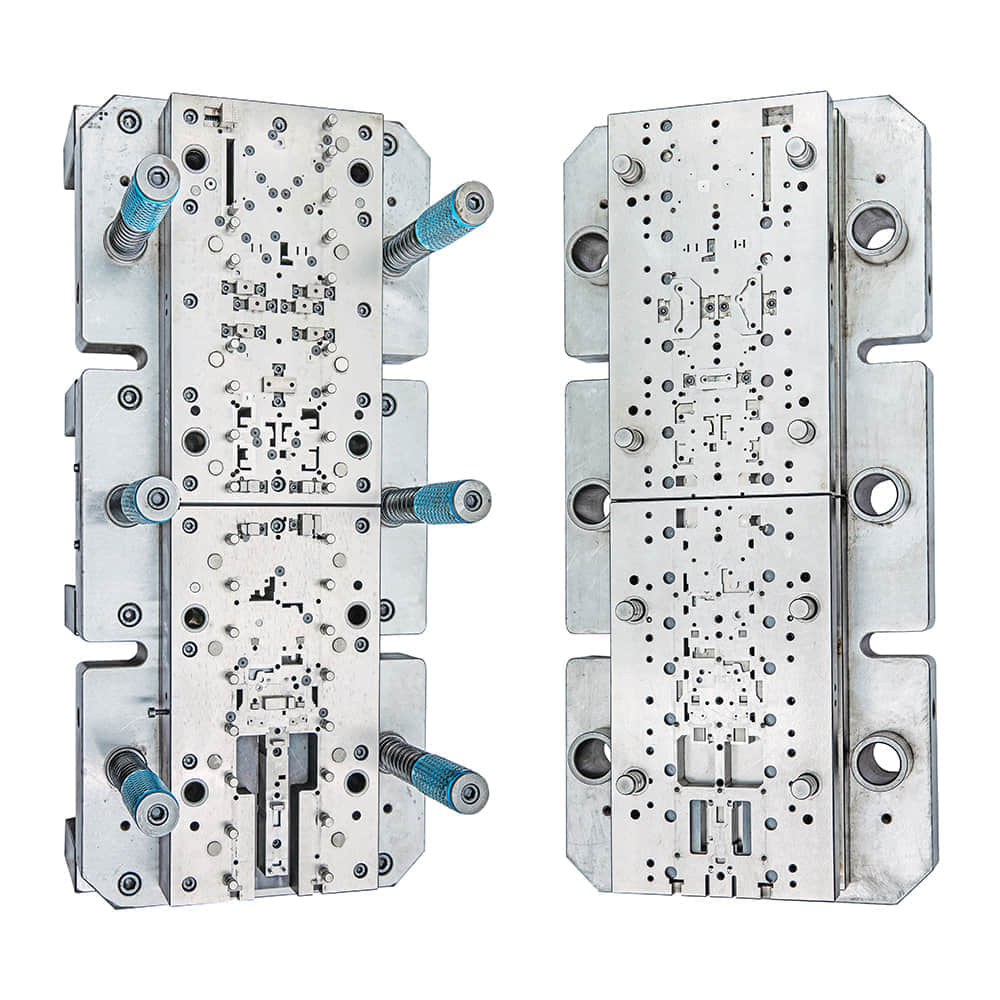

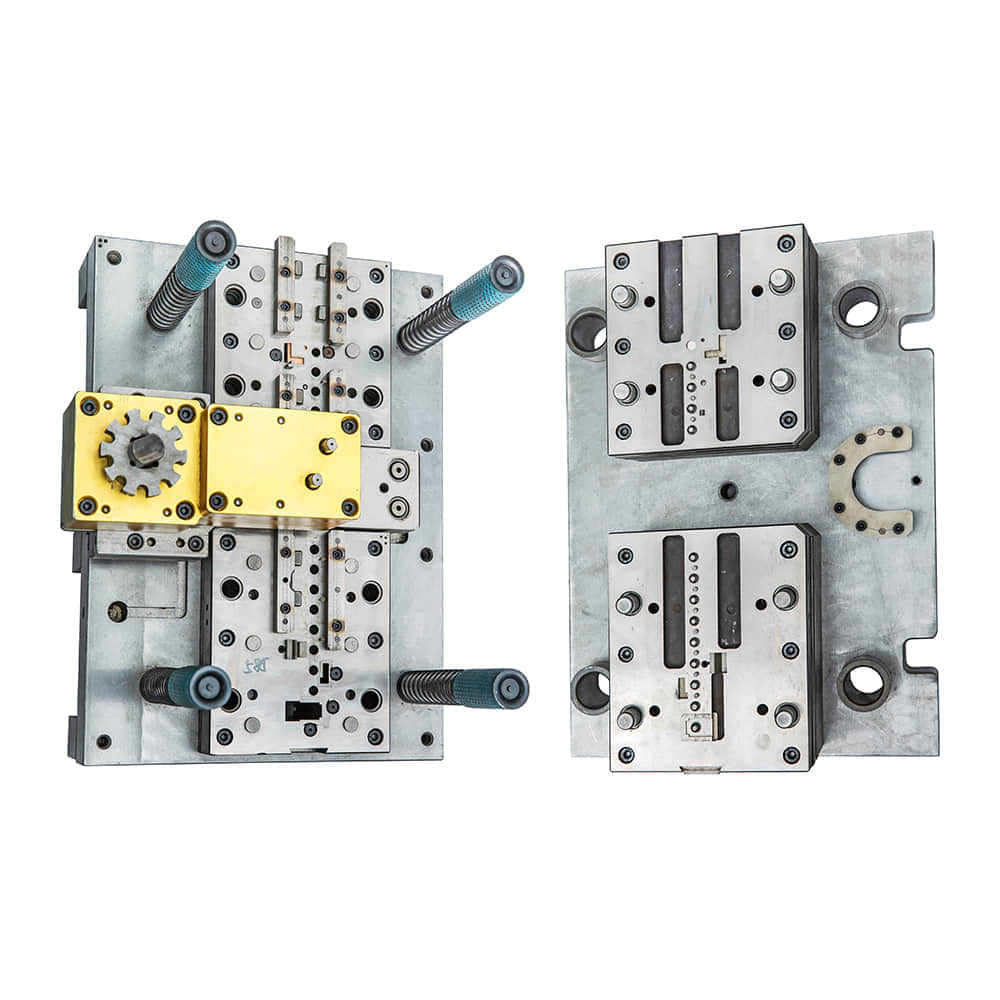

In the realm of manufacturing, where precision and innovation converge, China stands tall as a global leader. Among its numerous industrial accomplishments, China’s hardware mold manufacturing industry has garnered substantial recognition. Renowned for its meticulous craftsmanship, cutting-edge technology, and unwavering commitment to quality, China’s hardware mold manufacturers have reshaped industries worldwide.

The Essence of China’s Hardware Mold Manufacturing Industry

China’s hardware mold manufacturing industry epitomizes the nation’s dedication to precision engineering. With a history spanning decades, the industry has evolved from its nascent stages to become a formidable force on the international stage. The manufacturers’ journey has been underpinned by a continuous pursuit of perfection, with an emphasis on refining techniques, enhancing materials, and embracing emerging technologies. Precision as the Cornerstone Precision is the cornerstone of China’s hardware mold manufacturing prowess. Manufacturers employ advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to meticulously plan every facet of the mold. This digital precision translates into tangible excellence, as molds are crafted with minute details that perfectly mirror the desired end product. The precision not only reduces the need for post-production modifications but also ensures a seamless manufacturing process. Innovative Technological Integration China’s hardware mold manufacturers are synonymous with innovation. The industry has seamlessly integrated modern technologies such as artificial intelligence, additive manufacturing, and advanced material science into their processes. This fusion of innovation and tradition has revolutionized the production of hardware molds, enabling intricate designs, complex geometries, and faster production cycles. The integration of robotics and automation has further optimized manufacturing processes, increasing efficiency and reducing human error. Global Impact and Collaborations The impact of China’s hardware mold manufacturers reverberates worldwide. Collaborations with international businesses have led to the creation of cutting-edge products across various sectors, including automotive, electronics, aerospace, and consumer goods. China’s manufacturers have demonstrated an adaptability to diverse industry needs, providing customized mold solutions that drive product development and innovation. As a result, the “Made in China” label is no longer just an indication of mass production but a stamp of quality and precision. Quality Assurance and Sustainability China’s hardware mold manufacturers uphold rigorous quality assurance standards. Stringent testing, inspection, and validation processes are embedded into every stage of production, ensuring that each mold meets the highest benchmarks of quality and performance. Furthermore, the industry has recognized the importance of sustainability. Efforts are being made to minimize waste, optimize energy usage, and explore eco-friendly materials, aligning with global initiatives for a greener future. A Glimpse into the Future The trajectory of China’s hardware mold manufacturing industry is poised for continued growth and innovation. The convergence of smart manufacturing, the Internet of Things (IoT), and data analytics is expected to further enhance precision, efficiency, and customization. As global industries evolve, China’s manufacturers are committed to leading the way, leveraging their expertise to shape new frontiers of possibility. In Conclusion China’s hardware mold manufacturers have transcended conventional boundaries, elevating themselves into the realm of precision engineering and innovation. Their indomitable spirit, coupled with a relentless pursuit of perfection, has established them as leaders in the global manufacturing landscape. With a legacy built on precision, innovation, collaboration, and sustainability, China’s hardware mold manufacturers continue to mold the future of industries worldwide.