In the dynamic world of industrial automation, the demand for efficient, reliable, and durable valve systems has grown exponentially. Among the various types of valves, the explosion-proof electric butterfly valve stands out as an essential component, especially in industries with potentially hazardous environments. These valves play a crucial role in controlling the flow of liquids and gases, ensuring the safety and efficiency of operations. China, as a global manufacturing hub, has positioned itself as a leading provider of explosion-proof electric butterfly valves. This article explores the characteristics, benefits, and advancements of China-based manufacturers in producing high-quality explosion-proof electric butterfly valves.

The Importance of Explosion-Proof Electric Butterfly Valves

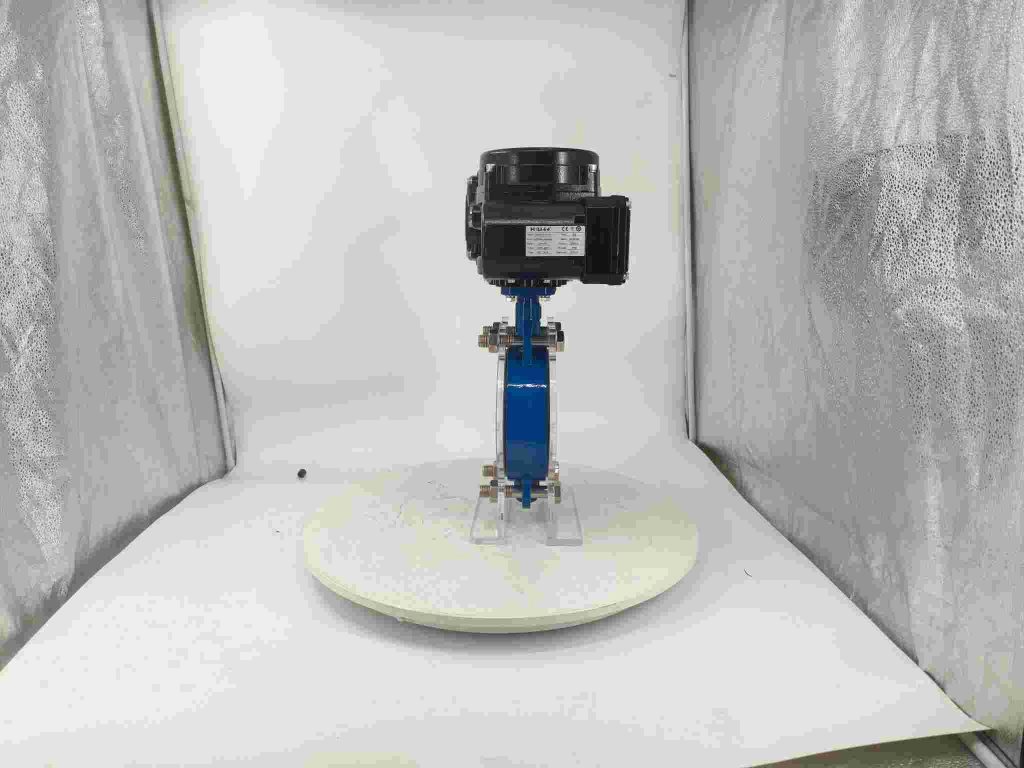

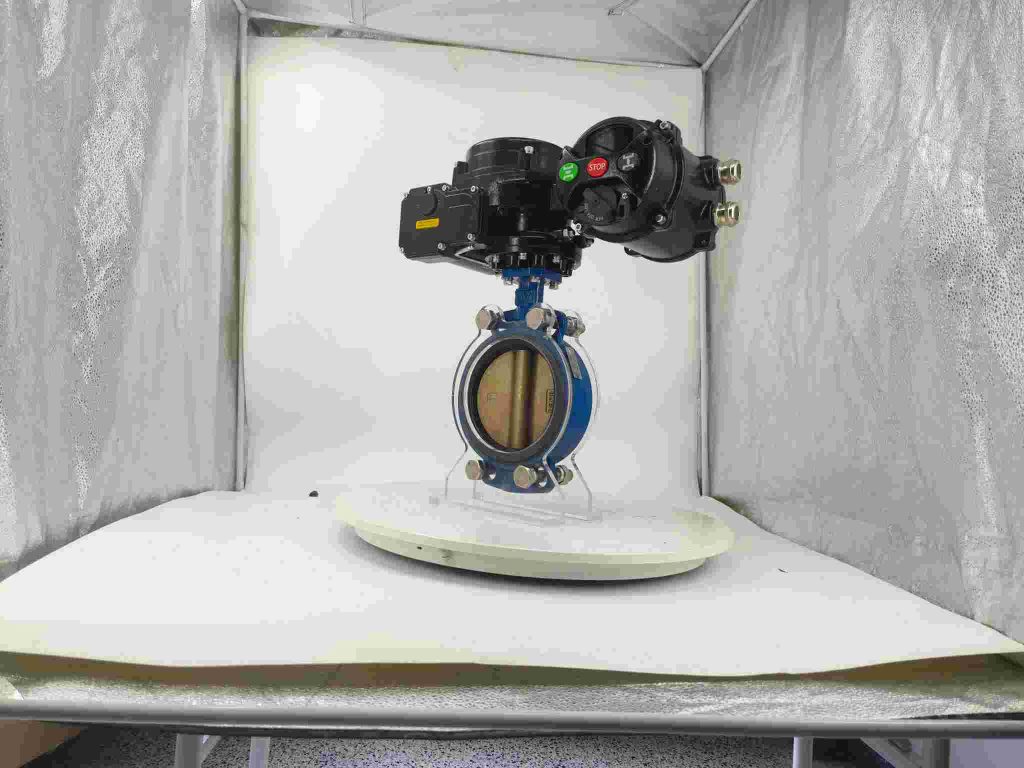

Explosion-proof electric butterfly valves are engineered to withstand explosive environments, offering a high degree of safety and operational reliability. These valves are specifically designed to handle situations where flammable gases, vapors, or dust are present, such as in chemical plants, refineries, oil and gas industries, and mining operations. The explosion-proof feature ensures that electrical components within the valve do not cause sparks or overheating, which could potentially ignite hazardous substances. The butterfly valve itself is known for its simple design, comprising a circular disc that rotates around a central axis to control flow. When coupled with electric actuators, these valves can be operated remotely, offering precise control over the flow of fluids. The explosion-proof feature adds an extra layer of security, making these valves indispensable in hazardous environments.