In recent years, the demand for reliable and safe industrial equipment has surged, particularly in sectors such as oil and gas, chemicals, and pharmaceuticals. One crucial component in these industries is the butterfly valve, specifically the explosion-proof electric butterfly valve. These valves are engineered to manage the flow of liquids and gases while ensuring safety in hazardous environments. This article delves into the significance of explosion-proof electric butterfly valves, their applications, and highlights leading manufacturers in China.

Understanding Explosion-Proof Electric Butterfly Valves

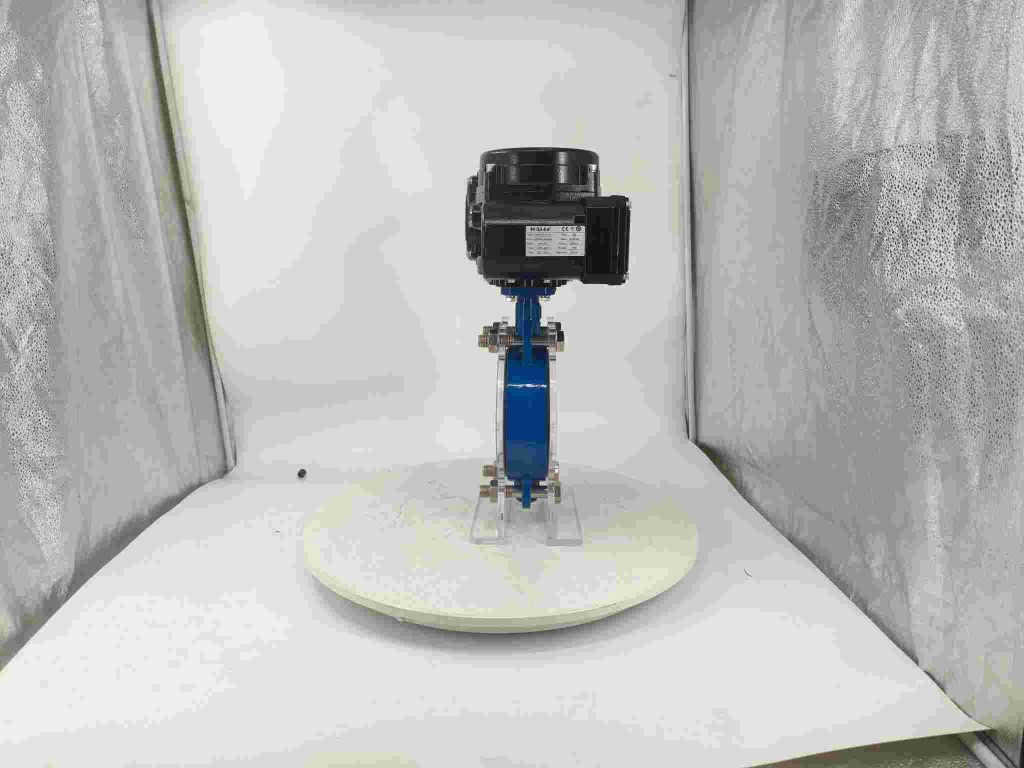

An explosion-proof electric butterfly valve is designed to prevent the ignition of explosive atmospheres, making it suitable for use in volatile environments. The valve features a disc that rotates on a shaft, allowing for quick opening and closing, which makes it an efficient choice for regulating flow. The electric actuator provides automation capabilities, enhancing operational efficiency and reducing manual intervention. The term “explosion-proof” refers to the valve’s construction, which includes robust materials and design features that prevent the escape of ignitable gases or vapors. This makes them essential in industries where flammable substances are present, such as chemical processing, oil refineries, and wastewater treatment plants.