In the realm of industrial automation and home appliance management, the temperature control relay plays a pivotal role in ensuring that systems operate within designated temperature ranges. These devices are essential for both maintaining efficiency and safeguarding equipment from the detrimental effects of overheating or excessive cooling. This article aims to explore the functionalities, applications, and importance of temperature control relays.

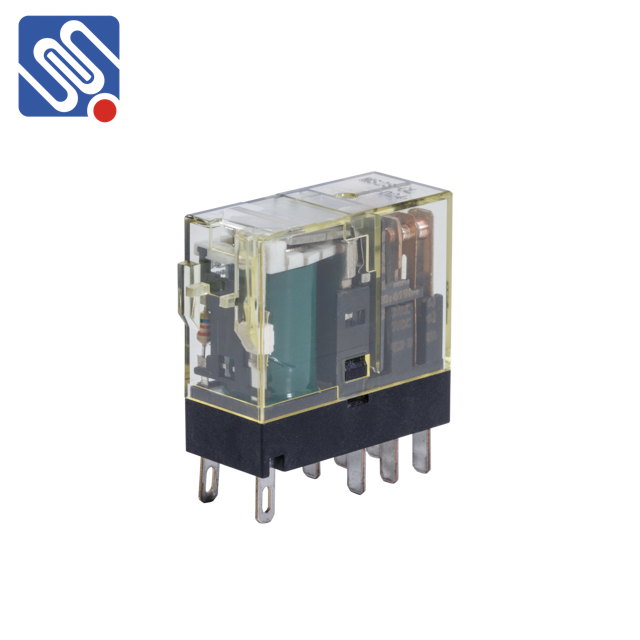

What is a Temperature Control Relay? A temperature control relay is an electromechanical device that monitors temperature and activates or deactivates equipment based on preset temperature thresholds. It typically consists of a temperature sensor, a relay switch, and a control circuit. The relay’s primary function is to open or close electrical contacts based on the temperature readings from the sensor. By doing so, it can control heating elements, cooling systems, or other associated machinery. How Does a Temperature Control Relay Work? The operational mechanism of a temperature control relay can be broken down into several key steps: