Relay technology has become a cornerstone in modern communication and networking solutions. Its ability to manage data flow efficiently, enhance connectivity, and ensure reliable communication makes it indispensable in various applications. This article aims to delve into Relay application notes, shedding light on their significance, implementation guidelines, and practical insights for developers and engineers.

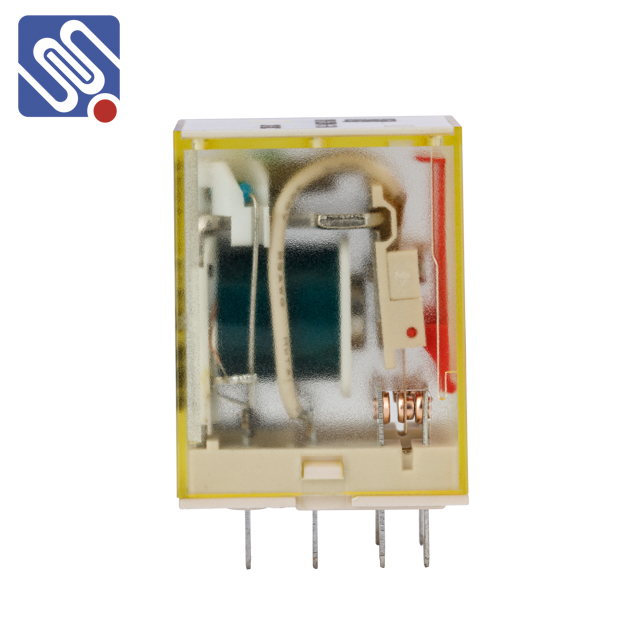

Understanding Relay Technology At its core, a relay is a device that enables the transmission of data from one point to another, often bridging the gap between different network segments. Relay functionality is crucial in scenarios where direct communication may not be feasible due to distance, protocol differences, or network architecture. In essence, relays facilitate the seamless flow of information, acting as intermediaries that enhance the robustness and efficiency of data transfer. The Importance of Relay Application Notes Relay application notes serve as a comprehensive guide for implementing relay systems in various projects. These documents often include detailed descriptions of relay components, operational protocols, and configuration settings. They address both the theoretical and practical aspects of relay technology, ensuring that users can effectively leverage the capabilities of relays in their specific contexts.