Ground Fault Protection Relay (GFPR) is an indispensable component of electrical safety systems, primarily utilized in various applications to safeguard personnel and equipment from electrical faults. These relays play a critical role in identifying and mitigating ground faults, which can lead to severe electrical accidents, equipment damage, and even fires. In this article, we will explore the features, functionality, applications, and importance of Ground Fault Protection Relays in modern electrical systems.

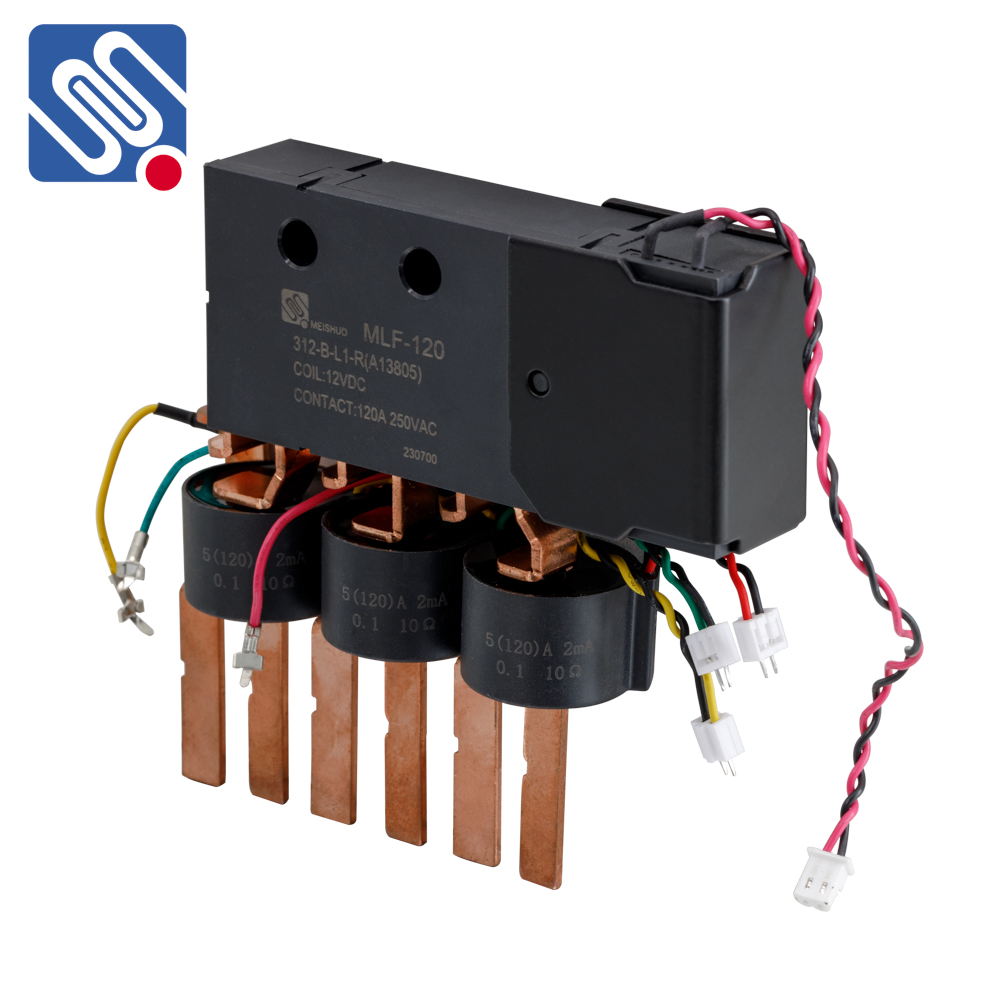

What is a Ground Fault Protection Relay? A Ground Fault Protection Relay is a device designed to detect imbalances in electrical current that indicate a ground fault condition. A ground fault occurs when electrical current unintentionally flows to the ground (earth) through an alternate path, often due to equipment failure, insulation breakdown, or accidental contact. When such incidents occur, they can pose serious safety risks, including electrical shock to personnel and damage to electrical equipment. How Does a Ground Fault Protection Relay Work? The operation of a GFPR is based on the principle of current monitoring. It typically employs core balance transformers (or zero-sequence current transformers) to measure the current flowing through a conductor system. Under normal operating conditions, the total current entering the system should equal the current leaving it. However, during a ground fault, a portion of the current diverts to the ground, creating an imbalance.