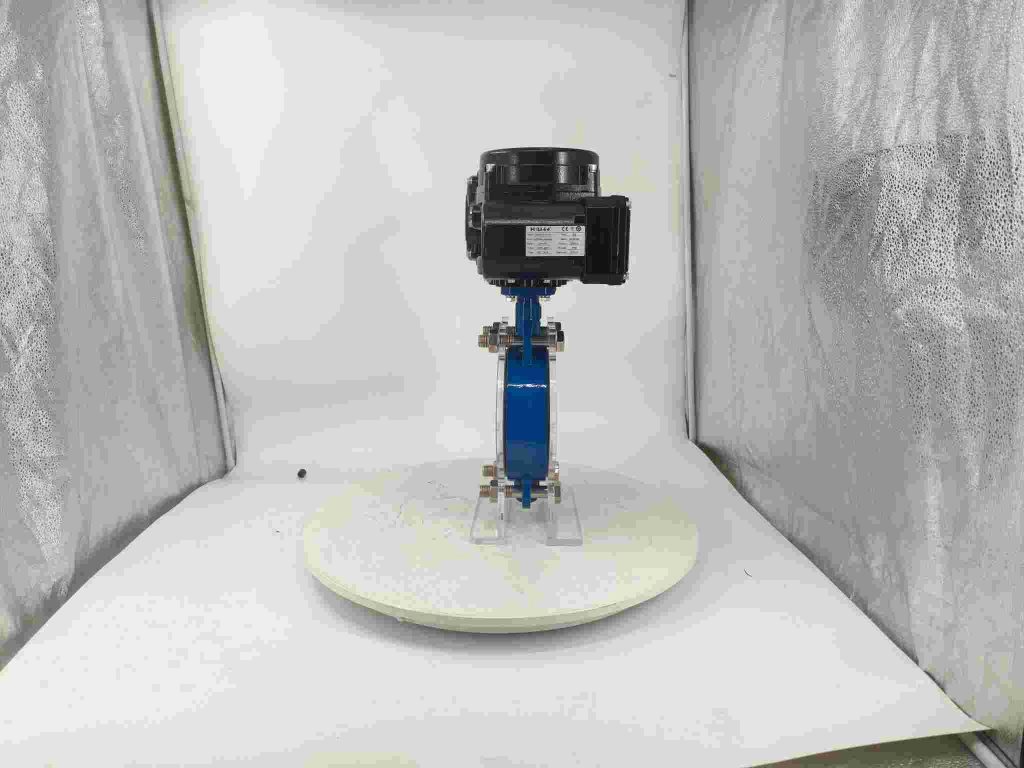

In the modern industrial landscape, the significance of precise flow control cannot be overstated. One of the paramount devices facilitating such control is the Electric Two-Seat Regulating Valve. This advanced valve type is an essential component in various industries, including chemical processing, oil and gas, water treatment, and HVAC (Heating, Ventilation, and Air Conditioning) systems. This article delves into the features, working principles, applications, and advantages of the electric two-seat regulating valve, highlighting its importance in industrial automation.

Key Features The electric two-seat regulating valve is distinguished by its innovative double-seat design. This structure comprises two parallel valve seats, allowing for greater flow capacity and enhanced control characteristics compared to traditional single-seat valves. The double-seat configuration minimizes flow turbulence and pressure loss, which is critical for maintaining the efficacy and efficiency of fluid systems. At the heart of this valve’s functionality is its electric actuator. Unlike pneumatic actuators, which require compressed air, electric actuators provide a more controlled and precise mechanism for valve operation. This means that the valve can be adjusted in response to a continuous signal—usually a 4-20mA current or a 0-10V voltage—allowing for smooth flow adjustments rather than merely open or closed states. The use of electric actuators also means that these valves can operate in environments where compressed air is impractical or unavailable.