In industries where safety is paramount, such as oil and gas, chemical processing, and power generation, equipment must be designed to withstand the most hazardous conditions. One such critical component is the Explosion Proof Electric Gate Valve. This specialized valve combines the reliability of a gate valve with the protection of explosion-proof technology, ensuring that operations continue smoothly even in environments prone to volatile or flammable substances.

What is an Explosion Proof Electric Gate Valve?

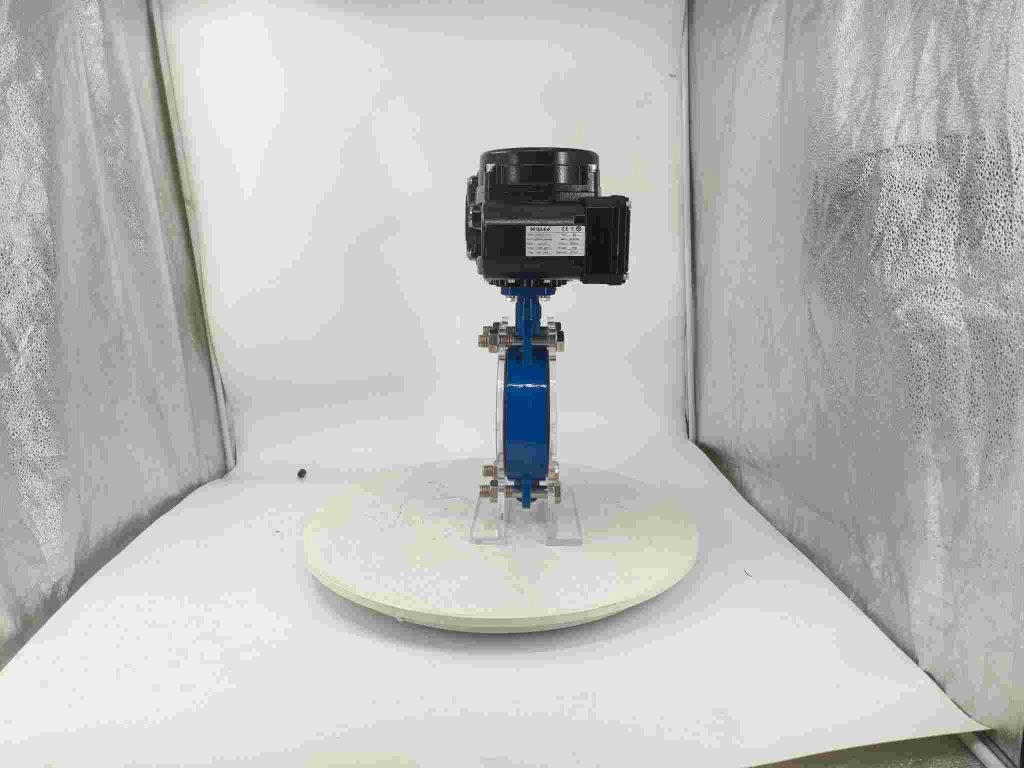

An Explosion Proof Electric Gate Valve is a type of industrial valve that is equipped with an electric actuator and is built to prevent the risk of explosion in environments where flammable gases, liquids, or vapors are present. The valve is typically installed in pipelines that carry hazardous materials, providing a reliable and secure means to control the flow of fluids or gases. Unlike traditional manual gate valves, which are operated by handwheels or levers, explosion-proof electric gate valves are controlled by electric motors, offering automation and remote operation. The electric actuator allows for precise control, enabling the valve to open or close based on signals from a control system, making it an ideal choice for modern industrial operations where automation and efficiency are critical.