In modern industrial applications, the efficient management of fluid flow is crucial. Among the various components that facilitate this, the Stainless Steel Electric Flange Ball Valve stands out for its reliability, durability, and performance. This article explores the key features, benefits, and applications of this type of valve, highlighting its significance in various industries.

What is a Stainless Steel Electric Flange Ball Valve?

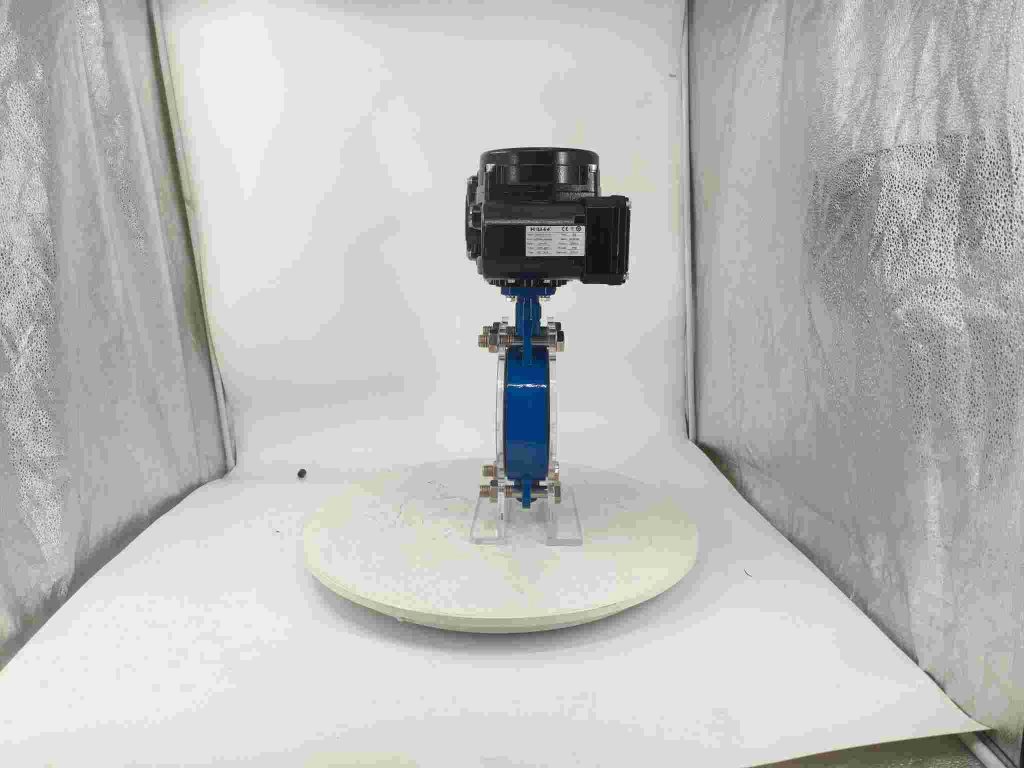

A Stainless Steel Electric Flange Ball Valve is a type of quarter-turn valve that uses a spherical disc, known as a ball, to control the flow of fluid. The ball has a hole through its center, and when aligned with the flow, allows fluid to pass through. Conversely, when the ball is rotated 90 degrees, the flow is obstructed. The “electric” component refers to the valve’s actuation through an electric motor, making it suitable for automated systems. The “flange” aspect indicates how the valve is attached to pipe systems, typically via flanged connections, allowing for easy installation and maintenance.