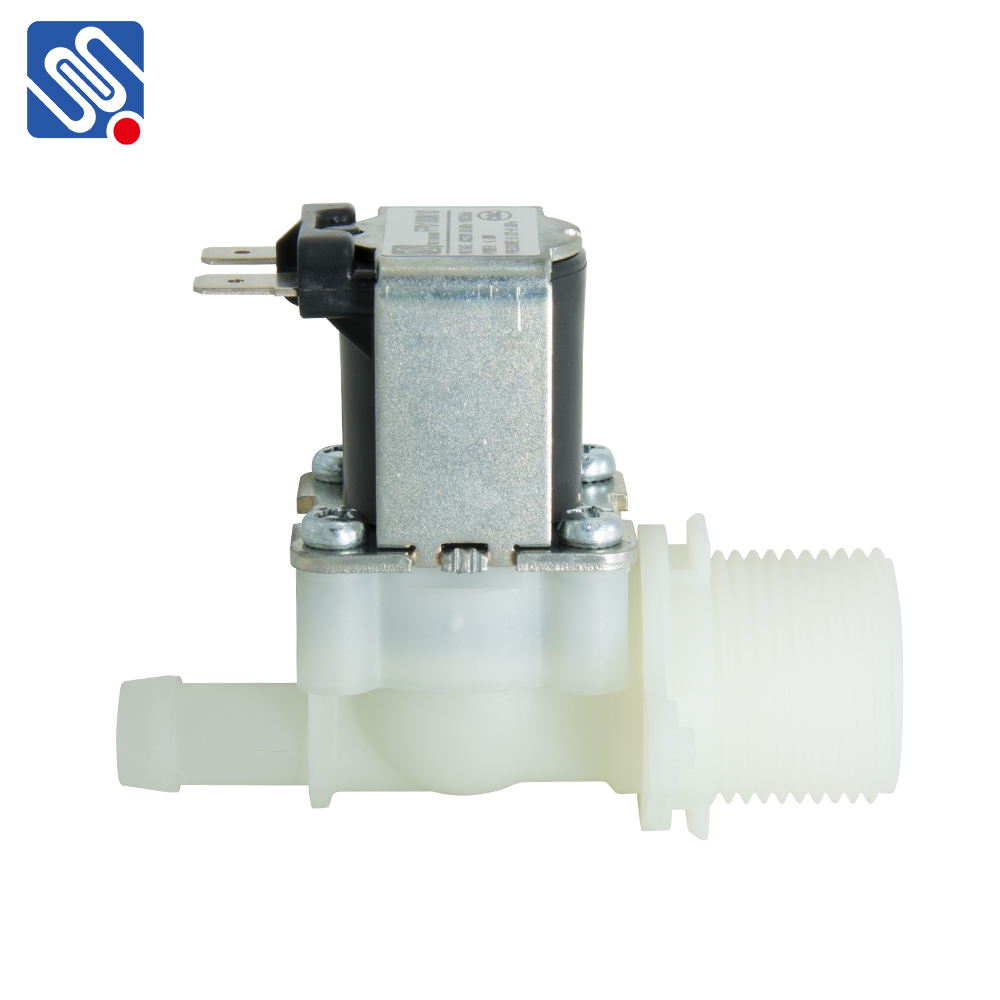

In the realm of automation and fluid management, the Durable Plastic Solenoid Valve stands out as a trusted device that has significantly advanced the way we control the movement of liquids and gases. These valves are designed to operate via electromagnetic mechanisms, allowing for precise control of fluid flow in various applications. As industries evolve and demand more reliable solutions, the use of durable plastic in solenoid valves has gained popularity due to its impressive characteristics and benefits.

Understanding Solenoid Valves A solenoid valve is an electromechanically operated valve used for controlling the flow of fluids. The magnetic coil within the valve activates or deactivates the flow path when electricity is applied. Solenoid valves are available in different configurations, such as normally closed or normally open, allowing for versatile applications. The introduction of durable plastics as a core material for these valves has revolutionized their use, particularly in environments where corrosion and chemical resistance are critical factors. Advantages of Durable Plastic Solenoid Valves