Hydrogen energy has emerged as one of the most promising solutions for sustainable energy in recent years. Among its various applications, hydrogen-powered technologies are being integrated into a variety of sectors, from transportation to industrial processes. One innovative use of hydrogen energy is in the development of hydrogen energy damper actuators, which hold the potential to revolutionize industries that rely on precise motion control and energy efficiency. This article delves into the function, benefits, and future prospects of hydrogen energy damper actuators, highlighting their significance in the broader context of energy sustainability.

What is a Hydrogen Energy Damper Actuator?

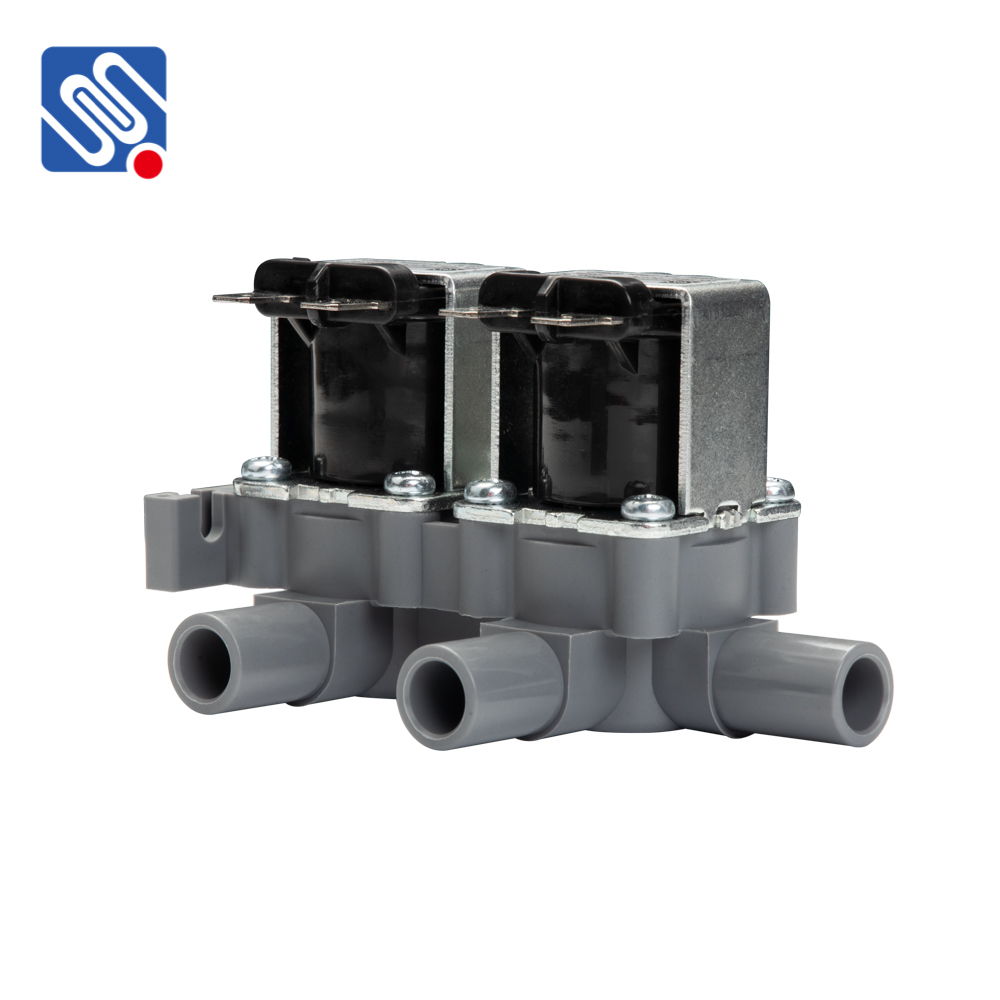

A damper actuator is a mechanical device used to control the movement or position of a damper, which regulates the flow of fluids, air, or gas within a system. These actuators are crucial in applications like HVAC systems, automotive suspensions, and industrial machinery, where precise control of damping forces is required for optimal performance. In a hydrogen energy damper actuator, the energy source driving the actuator’s movement is hydrogen fuel. By utilizing hydrogen as a power source, these actuators eliminate the need for conventional power supplies, such as electric motors or hydraulic systems, which may depend on fossil fuels or electricity generated from non-renewable sources. The unique advantage of using hydrogen is its clean energy properties: when hydrogen reacts with oxygen in a fuel cell to produce power, the only byproduct is water vapor, making it an environmentally friendly alternative to traditional energy sources.