In the ever-evolving world of HVAC (Heating, Ventilation, and Air Conditioning) systems, the efficiency and effectiveness of climate control solutions are paramount. One crucial component that plays a significant role in achieving optimal indoor environments is the damper actuator. As a specialized field, the role of a damper actuator manufacturer is essential for providing high-quality products that meet the diverse needs of both residential and commercial applications.

Understanding Damper Actuators

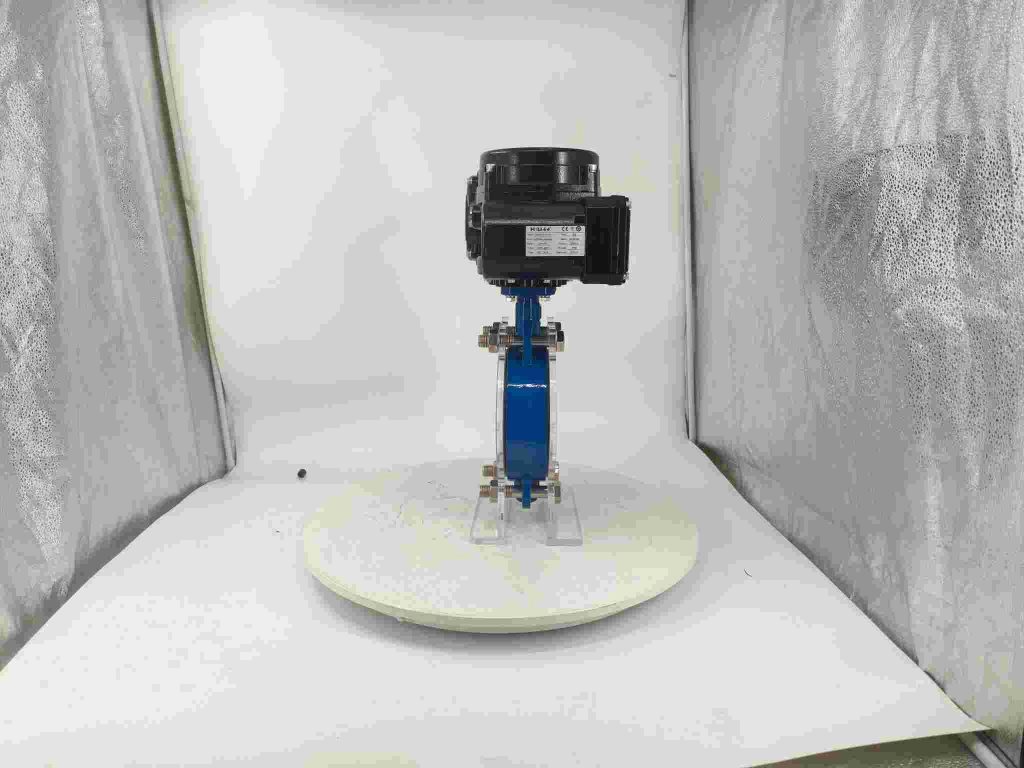

Damper actuators are devices responsible for controlling the flow of air in ducts, ensuring that HVAC systems operate efficiently. These actuators regulate the opening and closing of dampers, which are movable plates that manage airflow based on environmental demands. By modulating air volume, they help maintain desired temperature levels and enhance overall energy efficiency. The Importance of a Damper Actuator Manufacturer A reputable damper actuator manufacturer plays a crucial role in the HVAC supply chain. Their products must adhere to stringent quality standards and industry regulations to ensure safety, reliability, and performance. A manufacturer’s commitment to quality often begins with the selection of materials. High-grade components ensure durability and longevity, which are vital in demanding environments where HVAC systems operate continuously.