In the ever-evolving landscape of industrial automation and control systems, the role of electric two-seat regulating valves has gained significant prominence. These valves are essential components used in various industries, including oil and gas, water treatment, chemical processing, and HVAC systems. As an OEM (Original Equipment Manufacturer) of electric two-seat regulating valves, understanding the intricacies of their design, functionality, and application is crucial for both manufacturers and end-users alike.

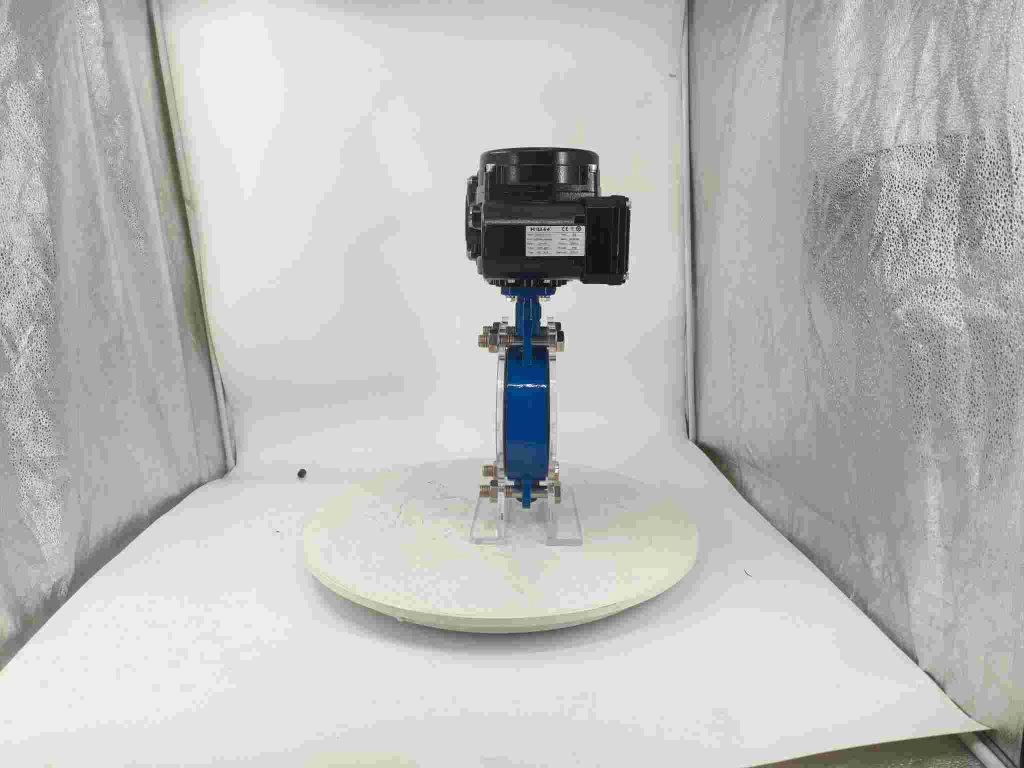

What is an Electric Two-Seat Regulating Valve? An electric two-seat regulating valve is designed to control the flow of liquids and gases in a pipeline system. The term “two-seat” refers to the valve’s design, which incorporates two seating surfaces that allow for precise flow regulation. This type of valve is actuated electrically, providing enhanced control and automation compared to traditional manual valves. The primary function of these valves is to modulate flow based on the required process conditions. By adjusting the position of the valve, operators can control variables such as pressure, temperature, and flow rate, ensuring that the system operates within optimal parameters. This capability is particularly beneficial in processes that demand high accuracy and responsiveness.